A method of laser cladding and anti-corrosion for steam turbine blades

A technology of steam turbine blades and laser cladding, which is applied in the coating process of metal materials, coatings, etc., can solve the problems of not meeting the requirements of water erosion resistance of blades, the production quality not meeting the requirements of use, and low production efficiency of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

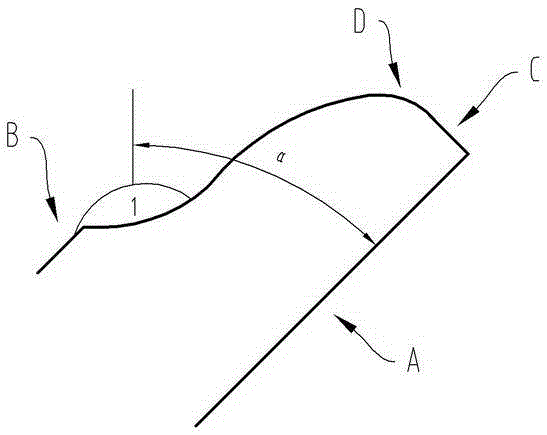

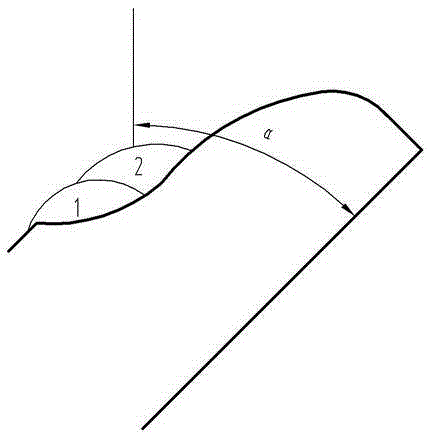

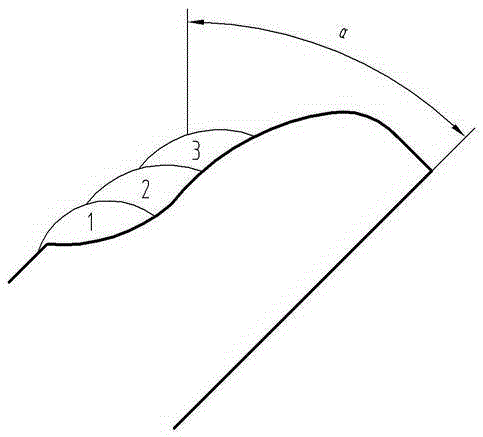

[0044] A 40-inch steam turbine final stage blade, its material is 0Cr17Ni4Cu4Nb, the laser cladding process is as follows, firstly, the cladding groove is polished with a grinding wheel, the blade is clamped to the cladding machine, and then a preheater is installed to complete the cladding The area is preheated, the preheating temperature is 100°C, the laser power is set to 2500W, the defocus is adjusted to a spot size of 5mm, and the powder feeding amount is set to 5g / min; The angle α between the directions of the laser beams is 55°, and the points are taught along the lower edge of the cladding tank, the data is collected to the software, the speed of the X-axis (blade radial direction) is set to 80mm / min, and the Y-axis ( Blade lateral) offset of 2.5mm (intake side direction), the software generates a cladding path program along the groove edge line Y direction offset 2.5mm, cladding, after the first pass cladding is completed, the next pass The edge line is used as the re...

Embodiment 2

[0047] A 67-inch steam turbine final-stage blade, whose cladding length and width are larger than the 40-inch blade in Example 1. The laser cladding process is as follows. Firstly, the cladding groove is ground with a grinding wheel, the blade is clamped to the cladding machine, and then a preheater is installed to preheat the cladding area. The preheating temperature is 300°C, and the laser power Set it to 3800W, adjust the defocus amount until the spot size is 6mm, and set the powder feeding amount to 6.5g / min. Then rotate the blade until the angle α between the reference plane of the inner arc of the blade and the direction of the laser beam is 35°, carry out teaching and tracing along the lower edge line of the cladding tank, collect the data to the software, and set the X-axis (blade radial) speed to 90mm / min, set the Y-axis (blade transverse) offset to 3mm (intake edge direction), and generate a cladding path program along the groove edge line Y-direction offset of 3mm b...

Embodiment 3

[0050] A 48-inch steam turbine final stage blade, its material is 1Cr12Ni3Mo2VN, the laser cladding process is as follows, firstly, the cladding groove is polished with a grinding wheel, the blade is clamped to the cladding machine, and then a preheater is installed to complete the cladding The area is preheated, the preheating temperature is 200°C, the laser power is set to 3000W, the defocus is adjusted to a spot size of 5.5mm, and the powder feeding volume is set to 5.75g / min. Then rotate the blade until the angle α between the reference plane of the inner arc of the blade and the direction of the laser beam is 45°, carry out teaching and tracing along the lower edge line of the cladding tank, collect the data to the software, and set the X-axis (blade radial) speed to 85mm / min, set the Y-axis (blade transverse) offset to 2.5mm (intake edge direction), and generate a cladding path program along the groove edge line Y-direction offset of 2.5mm by the software for cladding, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com