Thixotropic slurry rock-carrying capacity simulation test platform

A technology of thixotropic mud and simulation platform, which is applied in soil material testing, material inspection, etc., and can solve problems such as the inability to obtain the rock-carrying effect of thixotropic mud ratio and grouting scheme, and the inability to adjust the structure to simulate different construction scenarios, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

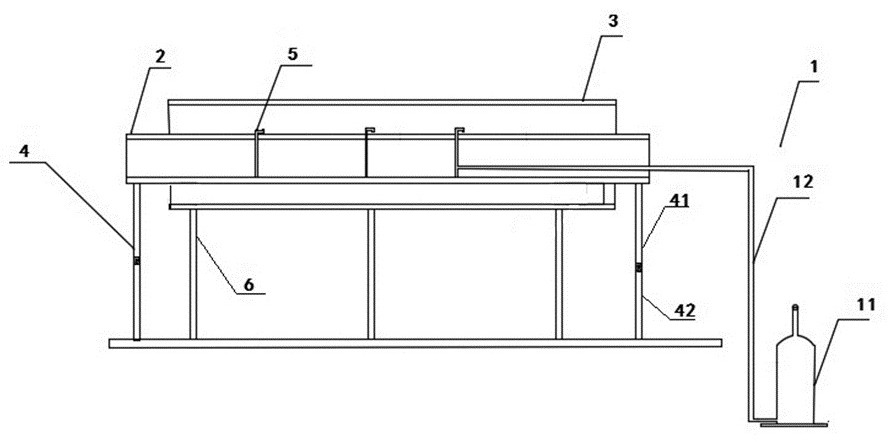

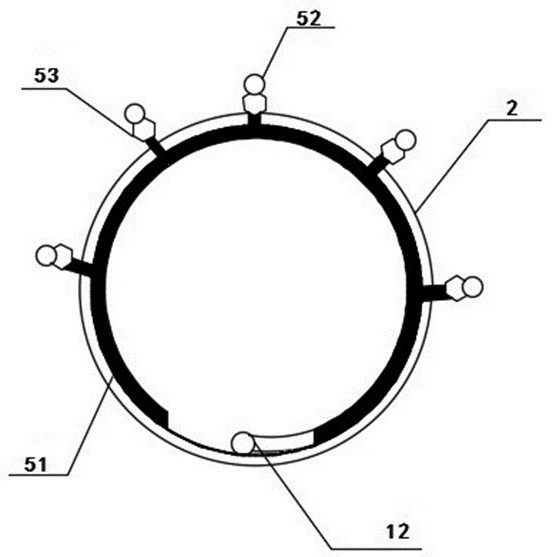

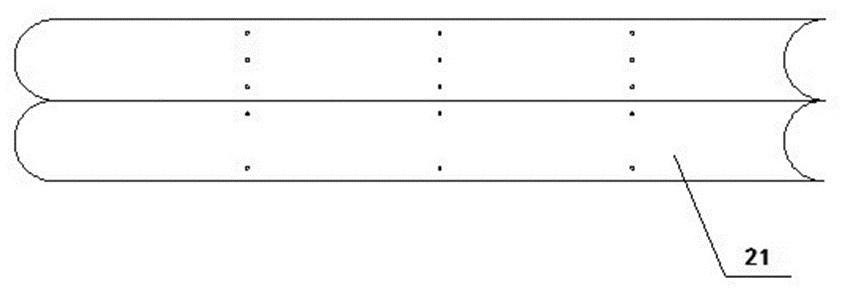

[0040] Example 1, such as figure 1 , figure 2 and image 3As shown, a thixotropic mud rock-carrying capacity simulation platform includes a grouting device 1, an inner pipeline 2, an outer pipeline 3, a slope adjustment device 4, a slurry ejector 5 and a supporting device 6; the grouting device 1 includes a grouting machine 11 and grouting pipeline 12; inner pipeline 2 is composed of pipeline monomer 21; slope adjustment device 4 includes rod one 41 and rod two 42; slurry outlet 5 includes slurry outlet pipeline 51, outlet nozzle 52 and anti-slurry backflow components 53.

[0041] The inner pipe 2 is steel pipe, the outer pipe 3 is transparent tempered glass, the inner pipe 2 is used to simulate the jacking pipe in actual construction, the outer pipe 3 is arranged outside the inner pipe 2, the outer pipe 3 is used to place rock debris, and the inner pipe The gap between 2 and the outer pipe 3 is the storage area, and the rock debris is placed in the storage area, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com