A kind of anti-temperature and anti-salt viscosity reducer for drilling fluid and its preparation and application

A technology of drilling fluid and viscosity reducer, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of drilling fluid thickening, short maintenance period, narrow application range, etc., achieve stable rheological properties, reduce Viscosity, good rock carrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

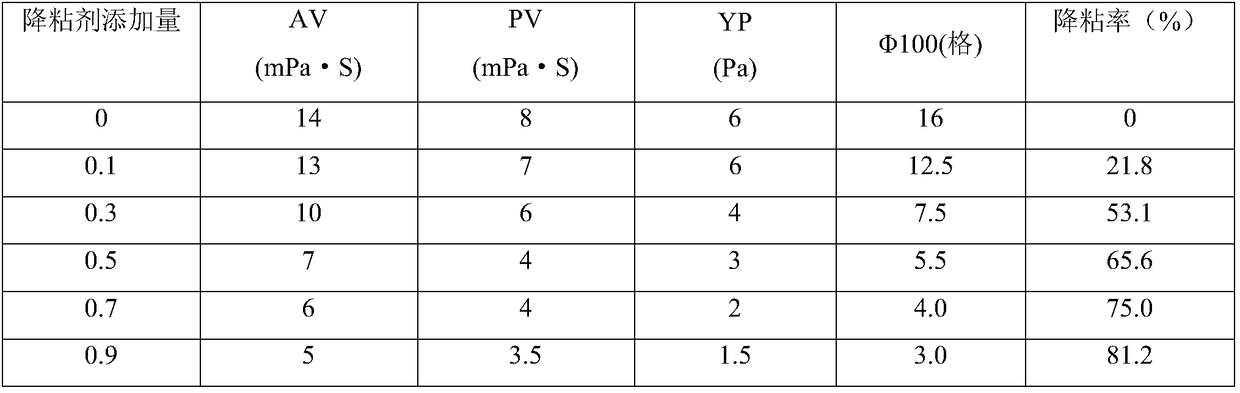

Examples

Embodiment 1

[0023] A temperature-resistant and salt-resistant viscosity-reducing agent for drilling fluid, the preparation method of which is as follows:

[0024] (1) Add maleic anhydride and water into the reaction kettle, stir to dissolve it fully, then raise the temperature to 60-80°C, add 2-acrylamide-2-methylpropanesulfonic acid and methacrylic acid while stirring at a constant speed Acyloxyethyltrimethylammonium chloride and ammonium persulfate, after reacting for 2 hours, adjust the pH value of the product to 7-9 with sodium hydroxide to obtain a light blue copolymer aqueous solution;

[0025] Wherein the mass ratio of the three monomers of maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid, and methacryloyloxyethyltrimethylammonium chloride is 35:45:20; On a mass basis, the concentration of the three monomers added, maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid and methacryloyloxyethyltrimethylammonium chloride, is 38wt% in total; the added persulfuric acid ...

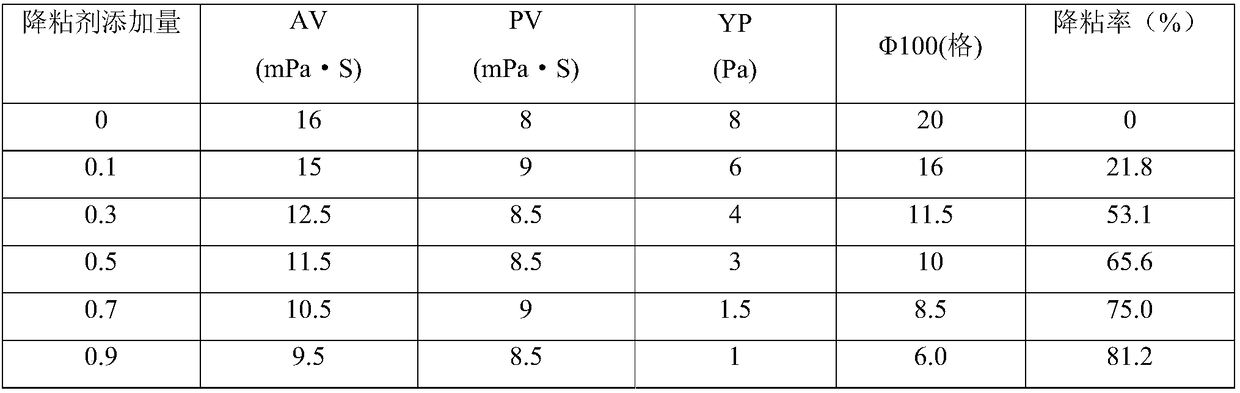

Embodiment 2

[0029] A temperature-resistant and salt-resistant viscosity-reducing agent for drilling fluid, the preparation method of which is as follows:

[0030] (1) Add maleic anhydride and water into the reaction kettle, stir to dissolve it fully, then raise the temperature to 60-80°C, add 2-acrylamide-2-methylpropanesulfonic acid and methacrylic acid while stirring at a constant speed Acyloxyethyltrimethylammonium chloride and potassium persulfate reacted for 2 hours, and the pH value of the product was adjusted to 7-9 with potassium hydroxide to obtain a light blue copolymer aqueous solution;

[0031] Wherein the mass ratio of the three monomers of maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid, and methacryloyloxyethyltrimethylammonium chloride is 32:42:22; On a mass basis, the concentration of the three monomers of maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid and methacryloyloxyethyltrimethylammonium chloride added is 35wt% in total; The concentration o...

Embodiment 3

[0035] A temperature-resistant and salt-resistant viscosity-reducing agent for drilling fluid, the preparation method of which is as follows:

[0036] (1) Add maleic anhydride and water into the reaction kettle, stir to dissolve it fully, then raise the temperature to 60-80°C, add 2-acrylamide-2-methylpropanesulfonic acid and methacrylic acid while stirring at a constant speed Acyloxyethyltrimethylammonium chloride and potassium persulfate, after reacting for 3 hours, adjust the pH value of the product to 7-9 with potassium hydroxide to obtain a light blue copolymer aqueous solution;

[0037] Wherein the mass ratio of the three monomers of maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid, and methacryloyloxyethyltrimethylammonium chloride is 32:40:18; On a mass basis, the concentration of the three monomers of maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid and methacryloxyethyltrimethylammonium chloride added is 36wt% in total; the added persulfuric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com