Non-excavation mud formula suitable for cobble clay composite stratum

A composite formation, trenchless technology, applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of increasing the frictional resistance of drilling tools, easy collapse of the hole wall, damage to formation stability, etc., to extend the life of the drill bit, Good rock-carrying effect and the effect of preventing instability and collapse of the hole wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The embodiment of the present invention also provides a kind of preparation method of the non-excavation mud formula that is applicable to pebble-clay composite formation, comprises the following steps:

[0022] (1) Weigh 100 parts by mass of water, and add 1-2 parts by mass of lubricating drag reducer in the water, stir for 10min under the stirring condition of 6000r / min rotating speed, and stir evenly;

[0023] (2) Add 4-6 parts by mass of dispersed film-forming agent to the solvent in the step (1) under stirring condition of 100r / min, and stir for 16h;

[0024] (3) Add 0.4-0.6 parts by mass of water sensitivity inhibitor to the solvent in the step (2) under stirring condition of 600r / min, and stir for 30min;

[0025] (4) Under the stirring condition of 6000r / min rotating speed, add 0.1-0.2 mass parts of fluid loss control agent and 0.2-0.4 mass parts of viscosity increasing agent to the solvent in the step (3) in sequence, and stir evenly to obtain a suitable Trench...

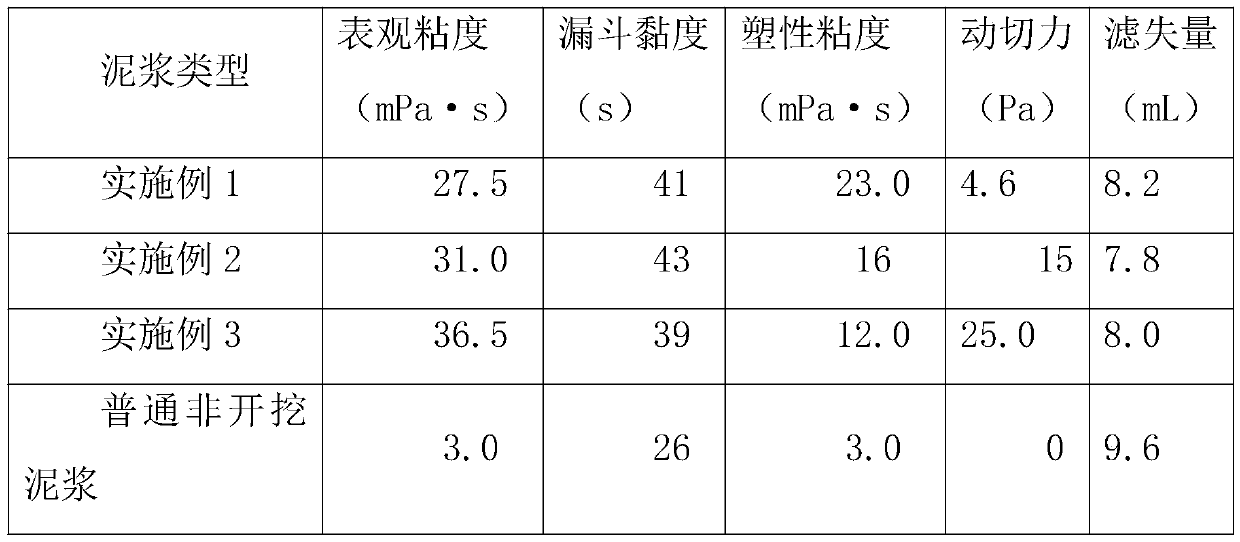

Embodiment 1

[0027] A non-excavation mud formula suitable for pebble-clay composite formations, prepared from the following raw materials: 1000ml of water, 40g of sodium bentonite, 1g of low-viscosity polyanionic cellulose, 2g of high-viscosity sodium carboxymethylcellulose, and lubricating drag reducer 10g, water sensitivity inhibitor 4g.

[0028] Preparation:

[0029] (1) Weigh 1000mL of water, add 0.59g sodium dodecylbenzenesulfonate (AS-12), 1.18g SP-80, 3.53g engine oil and 4.7g saponified oil into the water, stir at 6000r / min Stir for 10 minutes under the same conditions, and mix evenly with 10g of lubricating drag reducer;

[0030] (2) Add 40 g of sodium bentonite to the solvent in the step (1) under 100 r / min stirring condition, and stir for 16 h;

[0031] (3) Add 3.33g SOLTEX to the solvent in the step (2) under stirring condition of 600r / min, stir for 30min, then add 0.67g polyacrylamide, stir for 30min;

[0032] (4) Under the condition of stirring at a rotating speed of 6000r...

Embodiment 2

[0034] A non-excavation mud formula suitable for pebble-clay composite formations, prepared from the following raw materials: 1000ml of water, 50g of sodium bentonite, 2g of low-viscosity polyanionic cellulose, 3g of high-viscosity sodium carboxymethylcellulose, and lubricating drag reducer 15g, water sensitivity inhibitor 5g.

[0035] Preparation:

[0036] (1) Weigh 1000mL of water, add 0.88g sodium dodecylbenzenesulfonate (AS-12), 1.76g SP-80, 5.29g engine oil and 7.06g saponified oil into the water, stir at 6000r / min Stir for 10 minutes under the same conditions, and mix evenly with 15g of lubricating drag reducer;

[0037] (2) Add 50 g of sodium bentonite to the solvent in the step (1) under 100 r / min stirring condition, and stir for 16 h;

[0038] (3) Add 4.17g SOLTEX to the solvent in the step (2) under stirring condition of 600r / min, stir for 30min, then add 0.83g polyacrylamide, stir for 30min;

[0039] (4) Under the condition of stirring at a rotating speed of 6000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com