Method and system for reconstructing phase voltage of permanent magnet synchronous motor

A permanent magnet synchronous motor, phase voltage technology, applied in electrical components, emergency protection circuit devices, etc., can solve the problems of space saving and cost reduction, and achieve the effect of saving space, improving reliability and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

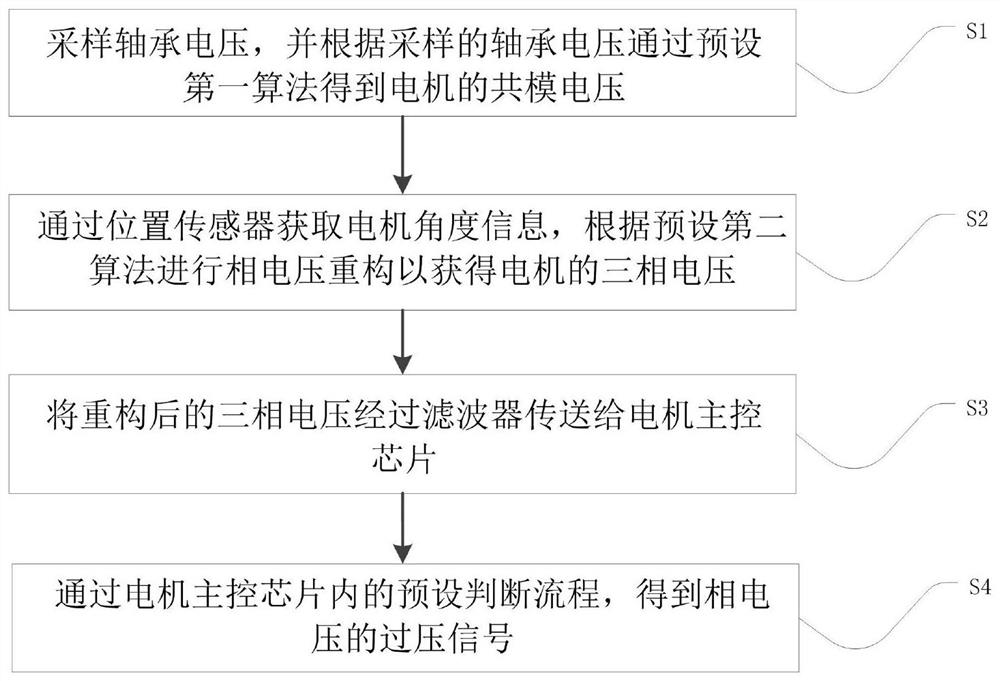

[0050] This embodiment provides a method for phase voltage reconstruction of a permanent magnet synchronous motor, such as figure 1 As shown, the method includes the steps of:

[0051] S1: Sample the bearing voltage, and obtain the common mode voltage of the motor through the preset first algorithm according to the sampled bearing voltage;

[0052] S2: Obtain the motor angle information through the position sensor, and perform phase voltage reconstruction according to the preset second algorithm to obtain the three-phase voltage of the motor;

[0053] S3: Send the reconstructed three-phase voltage to the motor main control chip through the filter;

[0054] S4: Obtain the overvoltage signal of the phase voltage through the preset judgment process in the motor main control chip.

[0055] Among them, the default first algorithm is:

[0056]

[0057] Among them, v b Indicates the bearing voltage; C wr Indicates the equivalent capacitance between the stator winding and the ...

Embodiment 2

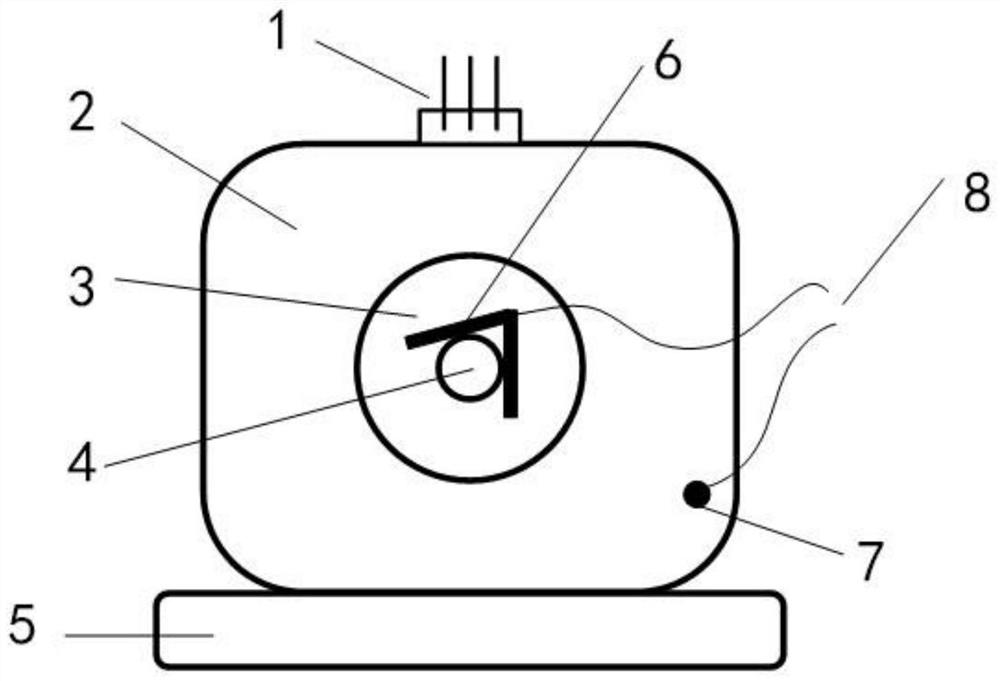

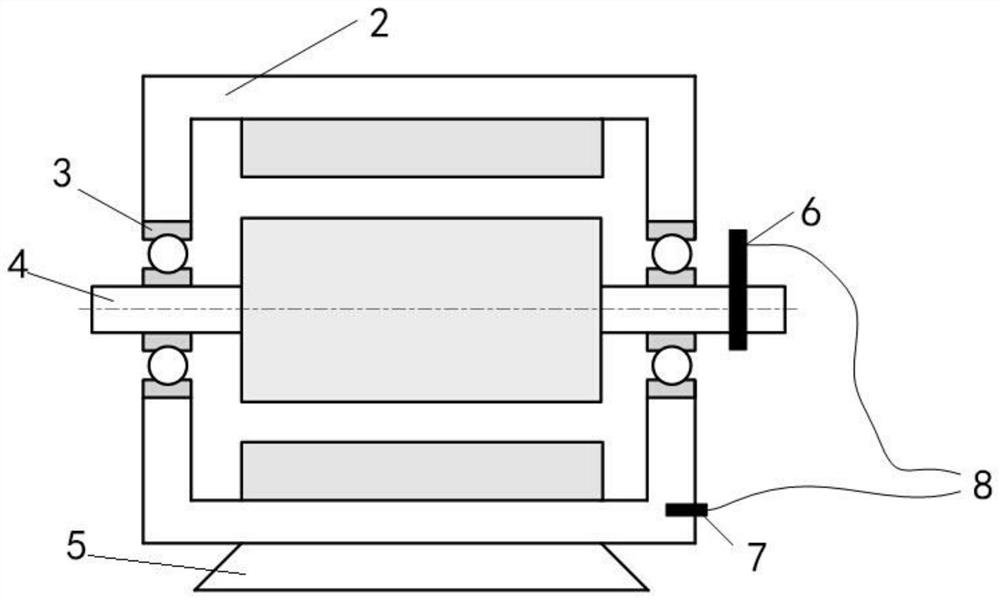

[0073] This embodiment provides a system for phase voltage reconstruction of a permanent magnet synchronous motor, such as Figure 6 As shown, the system includes:

[0074] Sampling module: used to sample the bearing voltage; the first calculation module: obtain the common mode voltage of the motor through the preset first algorithm according to the sampled bearing voltage; the acquisition module: used to obtain the motor angle information; the second calculation module: according to the preset The second algorithm performs phase voltage reconstruction to obtain the three-phase voltage of the motor; transmission module: used to transmit the reconstructed three-phase voltage to the main control chip of the motor through a filter; Set up the judgment process to get the overvoltage signal of the phase voltage.

[0075] Specifically, the module is used to sample the bearing voltage, and the common-mode voltage of the motor is obtained by the first algorithm module; combined with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com