Acoustic resonator and preparation method thereof

A technology of acoustic wave resonators and through-slots, applied in the field of microelectronics, can solve problems such as frequency adjustment of clutter acoustic wave resonators, and achieve the effects of reduced area, large capacitance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

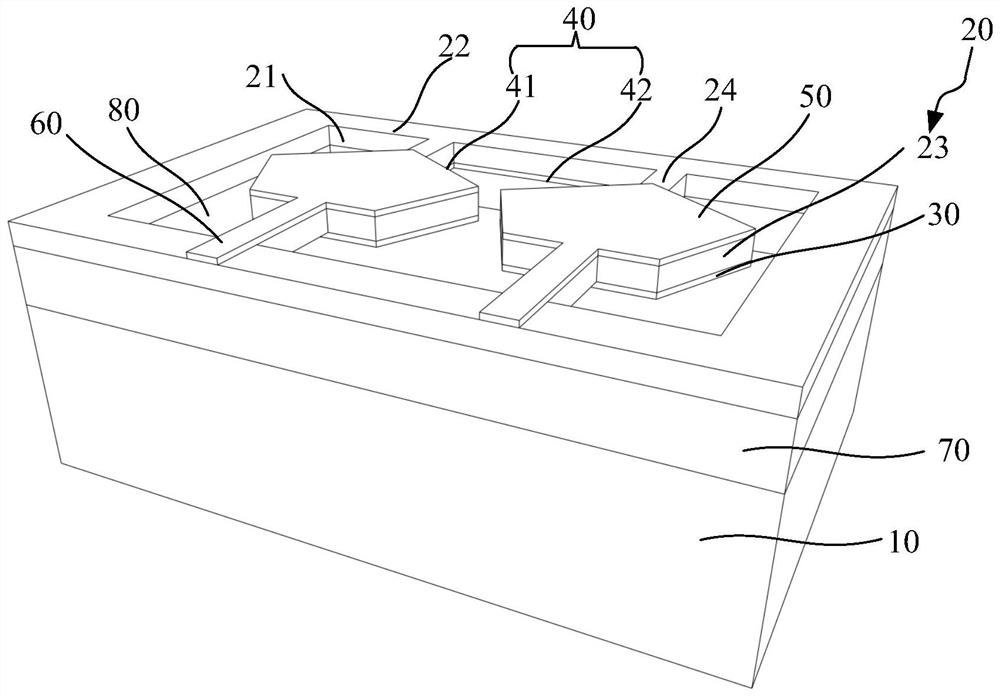

[0087] Such as figure 1 As shown, the present embodiment provides an acoustic wave resonator, and the acoustic wave resonator includes:

[0088] supporting substrate 10;

[0089] The piezoelectric layer 20 is formed on the upper surface of the support substrate 10; the piezoelectric layer 20 includes: a through groove 21, an edge support structure 22 and N effective piezoelectric structures 23, and the through groove 21 is formed on the In the piezoelectric layer 20 and the supporting substrate 10 is exposed, the edge support structure 22 is formed on the periphery of the through groove 21, and the effective piezoelectric structures 23 are arranged in parallel and spaced in the through groove 21 , and fixed to the opposite sides of the edge support structure 22 by engaging arms 24;

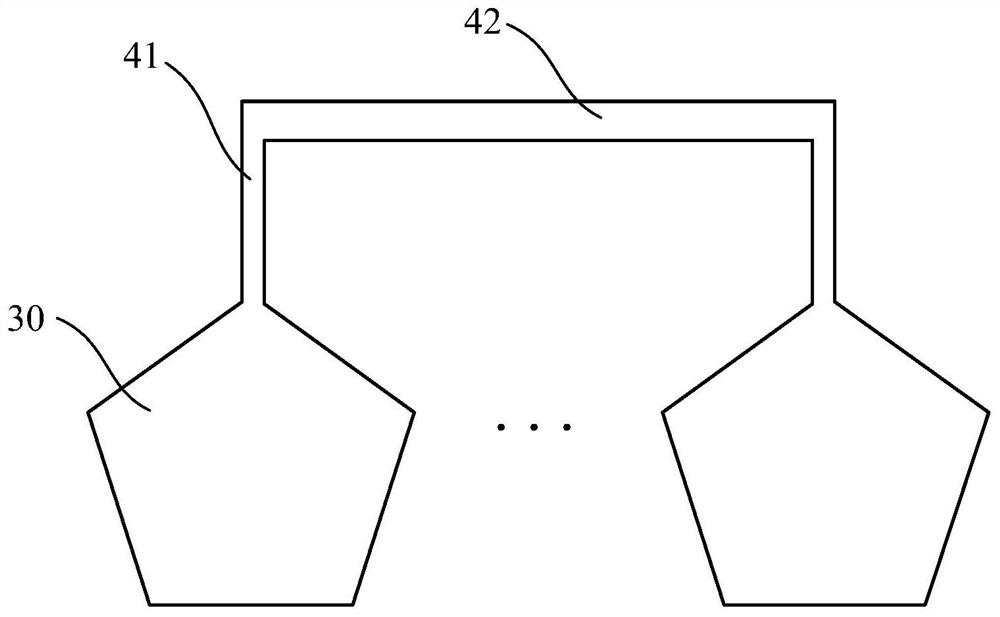

[0090] N bottom electrodes 30 correspond one-to-one to the N effective piezoelectric structures 23, and are formed between the effective piezoelectric structures 23 and the support substrate 10;...

Embodiment 2

[0103] Such as image 3 As shown, this embodiment also provides a preparation method of an acoustic wave resonator, the preparation method comprising:

[0104] 1) providing a supporting substrate 10;

[0105] 2) forming N bottom electrodes 30 on the upper surface of the support substrate 10, wherein the N bottom electrodes 30 are led out through the bottom electrode connection structure 40 and connected to each other;

[0106] 3) Forming a piezoelectric material layer 90 on the upper surface of the structure obtained in 2), and patterning the piezoelectric material layer 90 to form a piezoelectric layer 20, wherein the piezoelectric layer 20 includes a through groove 21, an edge support structure 22. Bonding arms 24 and N effective piezoelectric structures 23, wherein the through groove 21 is formed in the piezoelectric material layer 90 and exposes the support substrate 10, and the edge support structure 22 is formed in the On the periphery of the through-slot 21, N effecti...

Embodiment 3

[0120] Such as Figure 5 As shown, the present embodiment provides a method for preparing an acoustic wave resonator, the preparation method comprising:

[0121]1) Provide a piezoelectric substrate 20', the piezoelectric substrate 20' includes a first surface and a second surface opposite to the first surface, and the first surface of the piezoelectric substrate 20' performing patterned ion implantation to form a damaged layer 100 in the piezoelectric substrate 20';

[0122] 2) forming N bottom electrodes 30 on the first surface of the piezoelectric substrate 20', wherein the N bottom electrodes 30 are led out through the bottom electrode connection structure 40 and communicated with each other;

[0123] 3) forming a bonding layer 70 on the upper surface of the structure obtained in 2), and using the bonding layer 70 to bond the structure obtained in 2) to the support substrate 10;

[0124] 4) Peel off and polish the structure obtained in 3) based on the second surface to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com