Mushroom stick forming machine

A molding machine and fungus rod technology, applied in horticulture, agriculture, plant cultivation, etc., can solve the problems of time-consuming, laborious and labor-intensive, limited number of bags, uncompacted compost, etc., to achieve accurate position, convenient movement, bag groove Ease of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

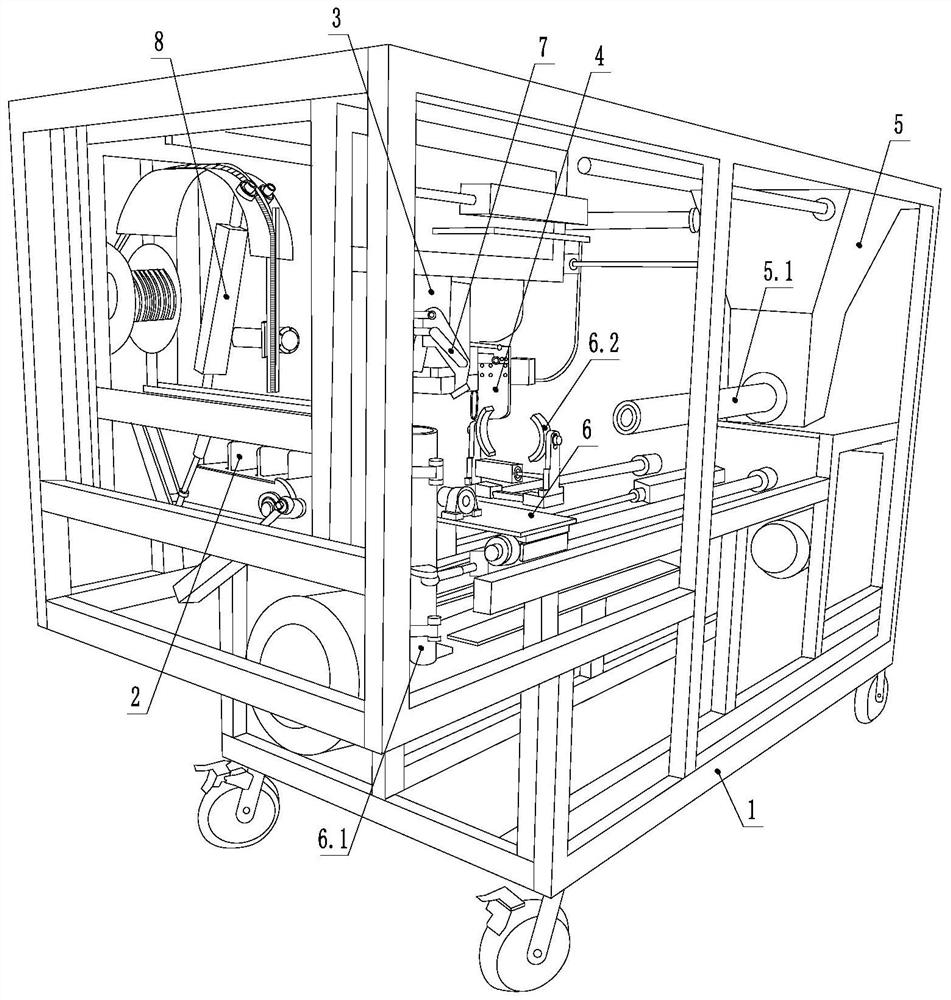

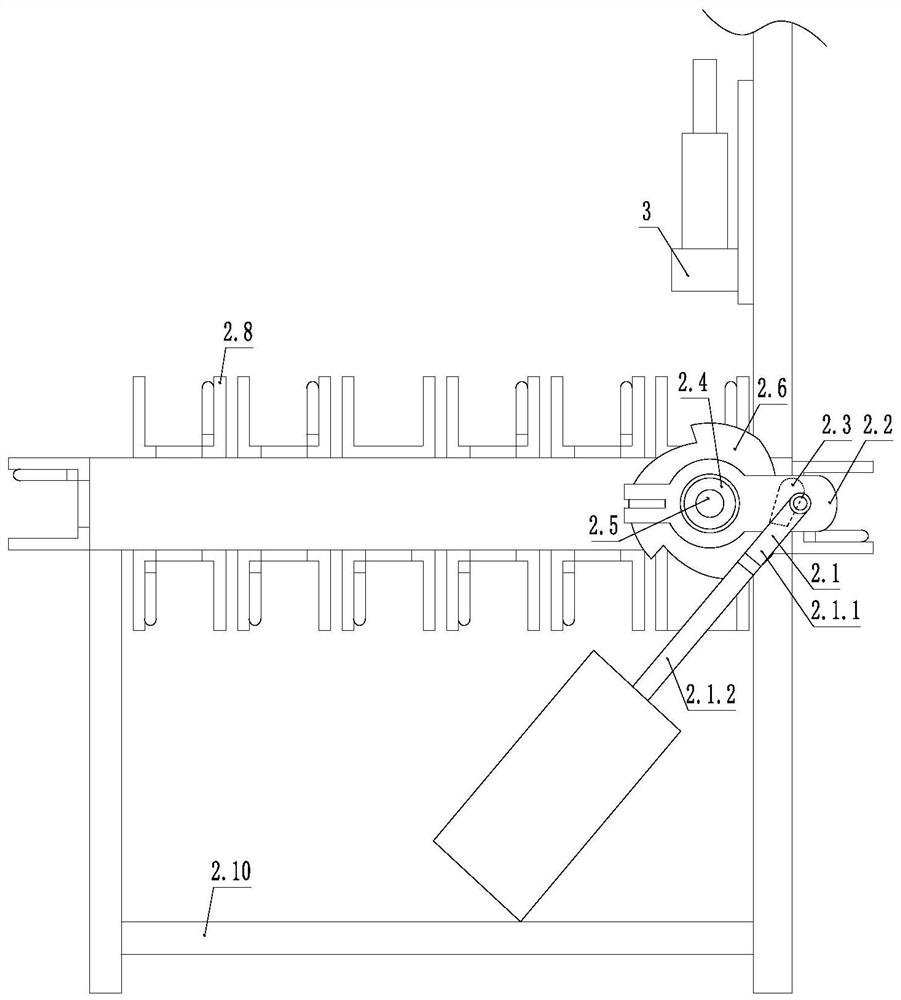

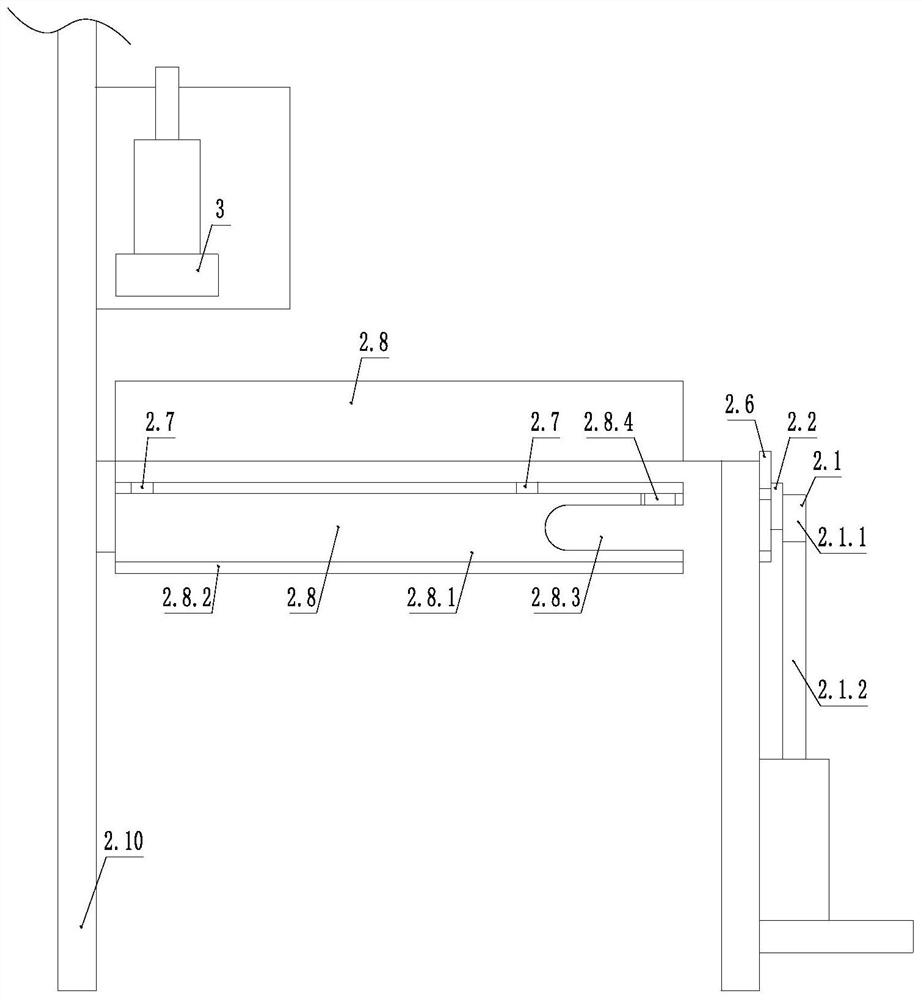

[0090] Such as Figure 1-12As shown, this bacterium stick molding machine in the present embodiment comprises frame 1, and the left middle part of frame 1 is provided with bag-releasing mechanism 2, and the right rear portion of bag-releasing mechanism 2 is equipped with suction bag mechanism 3, and machine The left rear portion of the frame 1 is provided with a bagging mechanism 4, the rear portion of the bagging mechanism 4 is provided with a control mechanism, the right rear portion of the frame 1 is provided with a discharge mechanism 5, and the right front portion of the frame 1 is connected to the discharge mechanism 5. A bag return mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com