Welding tool for engine base and rack of diesel engine

A welding tool and diesel engine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of laborious installation and disassembly, hidden dangers, complicated disassembly, etc., to ensure stability, improve welding quality, The effect of reducing the hidden danger of wear and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Such as Image 6 , 7 As shown, after the assembly is completed, the structure diagram of the workpiece 22 to be welded is given. It can be seen from the figure that the workpiece 22 includes structures such as side plates, end plates and web plates. After the basic assembly of the workpiece 22 is completed and completed by spot welding After the initial positioning, it is necessary to use welding to achieve complete fixation of adjacent parts. In the welding process, flat welding is easier to improve welding quality than overhead welding and vertical welding. Therefore, when welding workpieces 22 such as the frame of the diesel engine and the machine base, there is a need to turn over to complete the corresponding weld seam by flat welding.

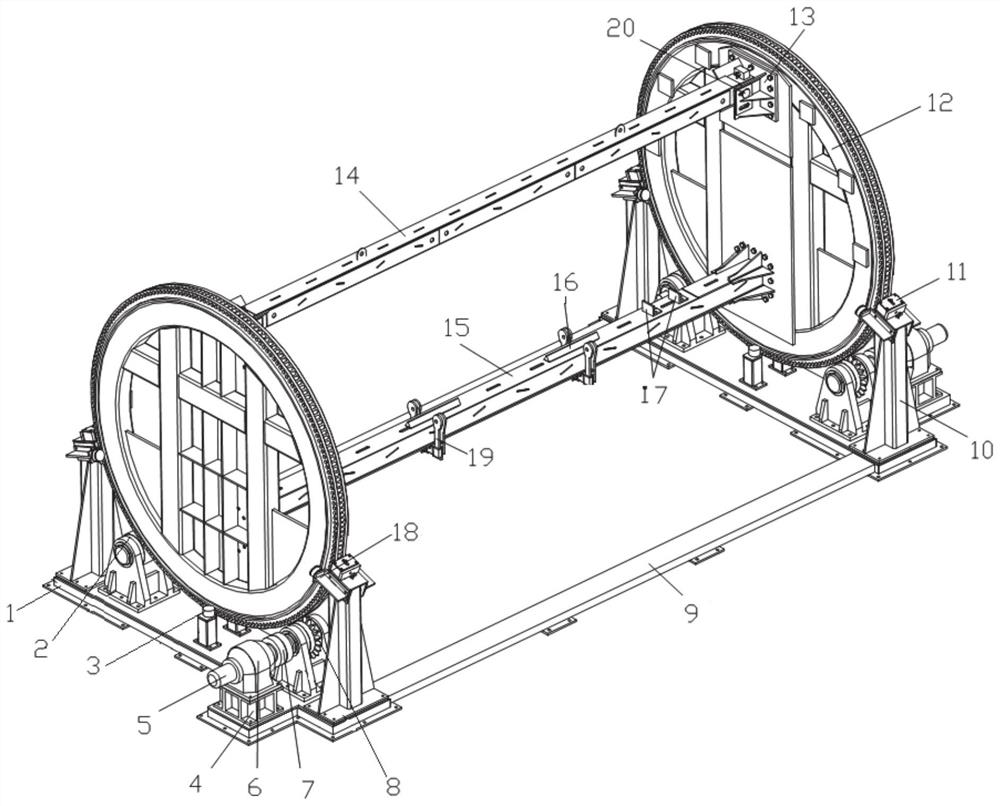

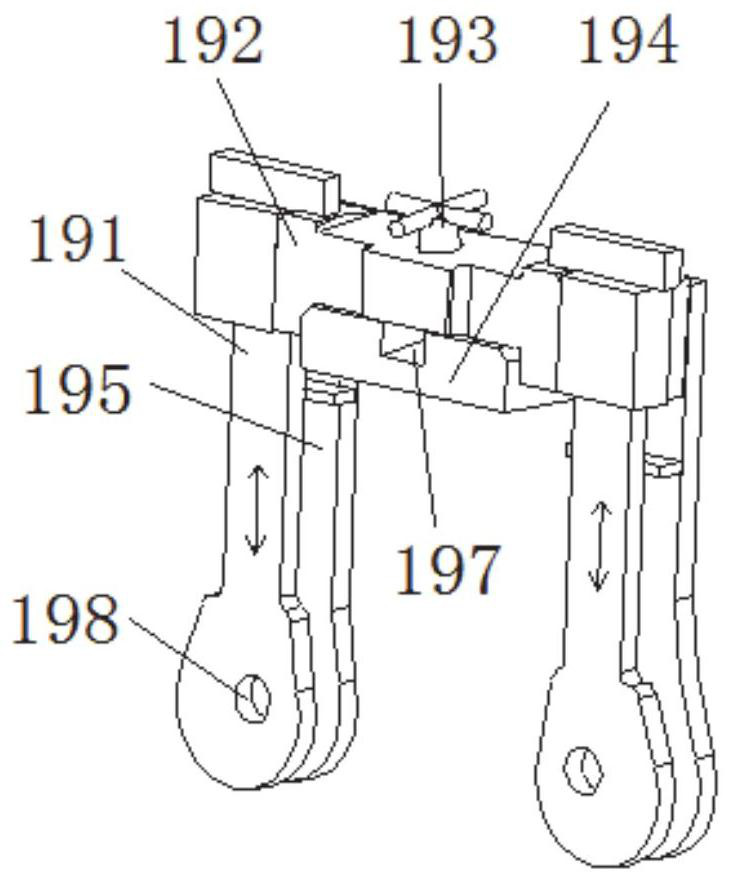

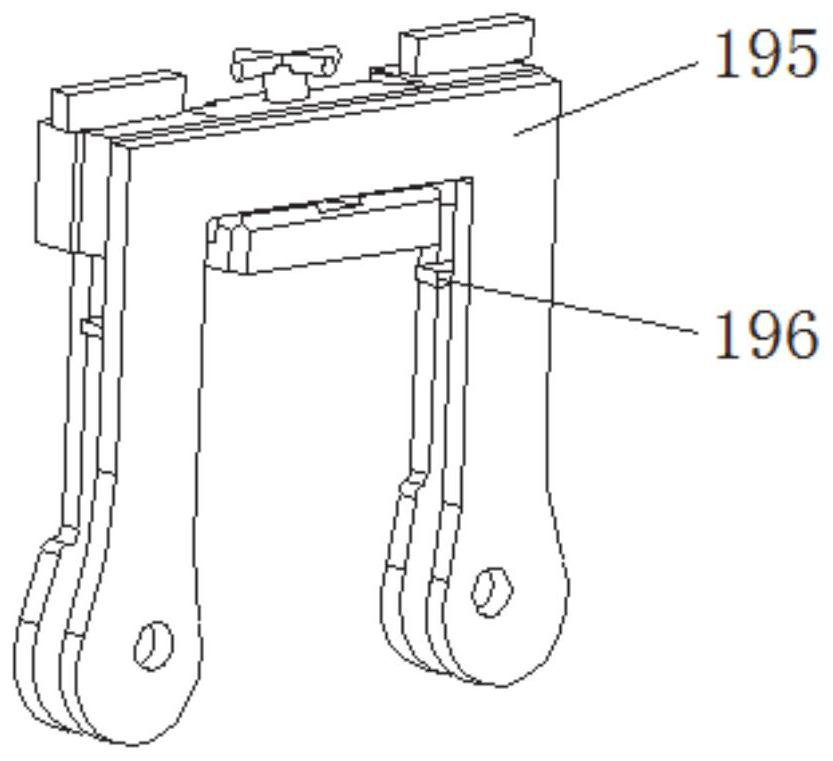

[0032] Such as figure 1 As shown, this embodiment provides a diesel engine base and a welding tool for the frame, including a turntable that can rotate along the horizontal axis and is fixed, and the turnframe has a horizontal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com