Bulk cargo ship with comprehensive energy-saving effect meeting EEDI high-stage requirements

An energy-saving, bulk carrier technology, applied in the direction of hull, ship construction, hull design, etc., can solve problems such as large gaps in requirements, difficulty in combined application, lack of application conditions for real ships, etc., to reduce CO2 emissions, The effect of reducing fuel consumption and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

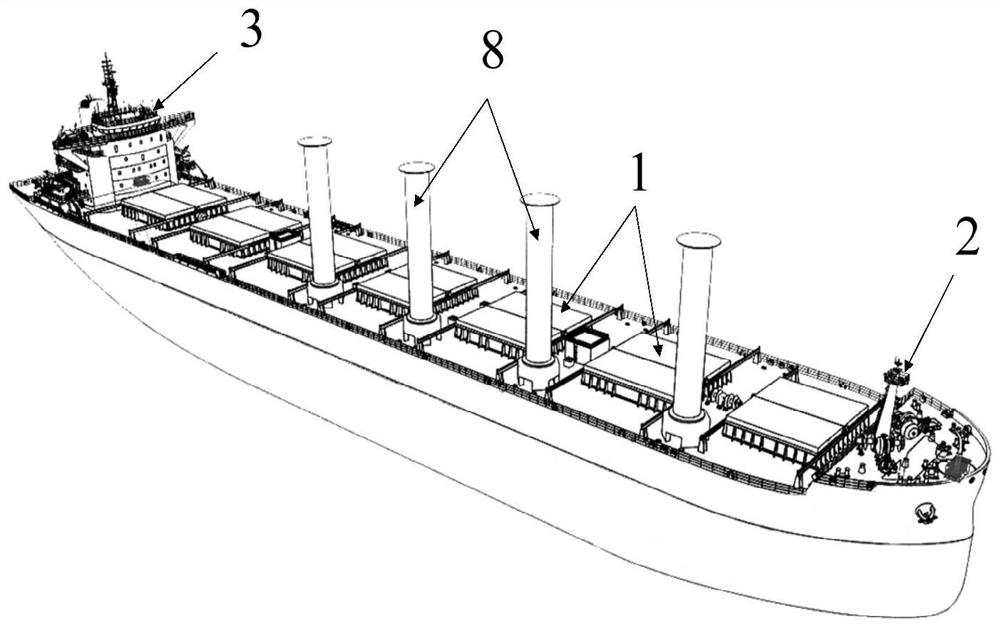

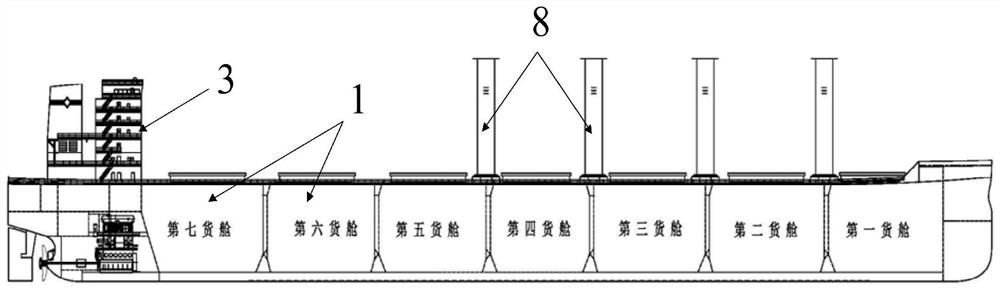

[0033] This application discloses a bulk carrier whose comprehensive energy-saving effect meets the high-stage requirements of EEDI. Please refer to figure 1 , the bulk carrier includes a hull and an air layer drag reduction system installed on the hull, a hydrodynamic energy-saving system, a wind booster system and a variable speed constant frequency shaft engine system.

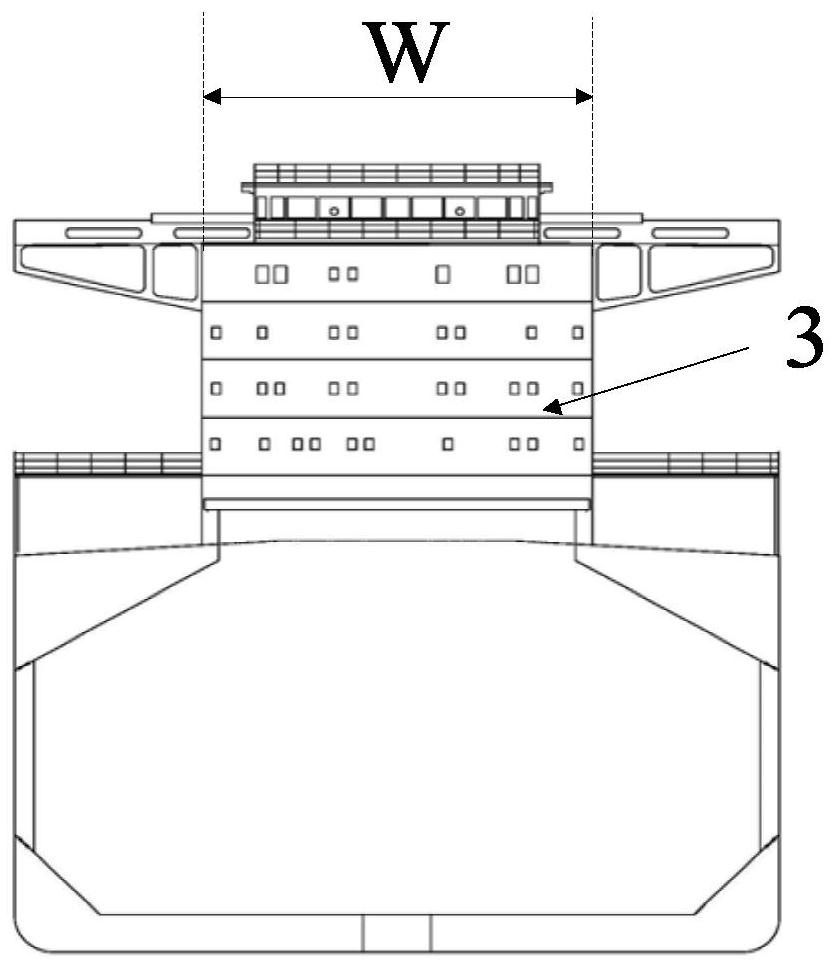

[0034] (1) Hull design. The hull adopts the linear design of vertical bow and square stern. The linear design of the bow is mainly to reduce the wave-making resistance and wave resistance increase, and the linear design of the stern is mainly to reduce the viscous pressure resistance and improve the wake field. form a low-resistance line design, such as figure 2 A structural view of the stern of the hull is shown.

[0035] The cargo compartment area inside the hull is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com