Surface fractal strengthened water electrolysis hydrogen production device and method

A hydrogen production device and water electrolysis technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of reducing the contact area between the electrolyte and the catalyst, affecting the conductivity of the electrolyte, affecting the catalytic effect, etc., so as to reduce the gas coverage and improve the The effect of electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

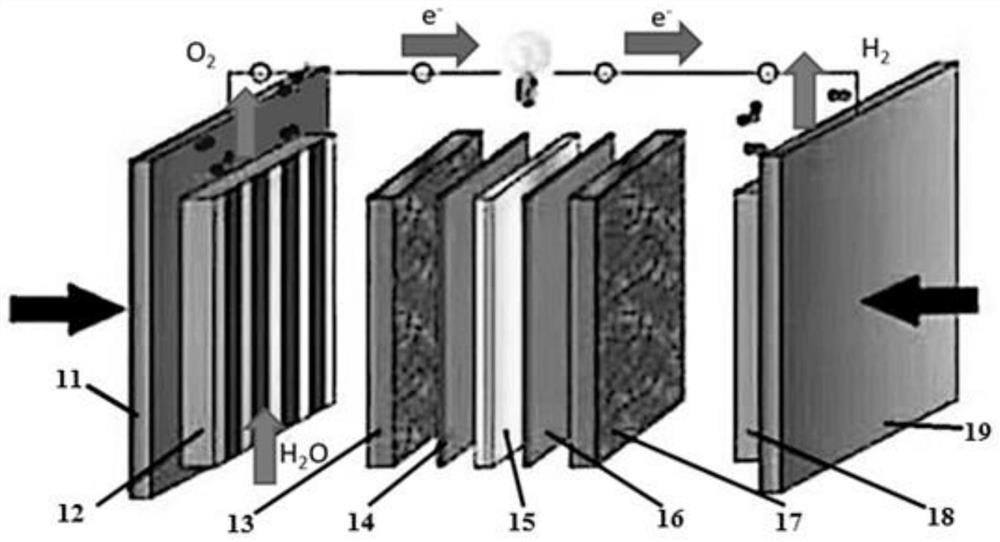

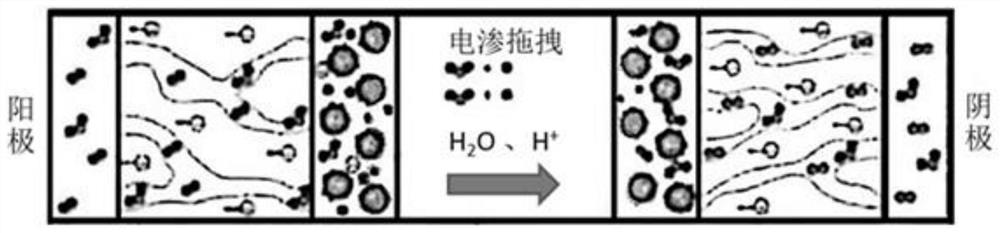

[0086] This embodiment provides a water electrolysis hydrogen production device, which includes an anode plate 11 with a first flow channel 12 and a cathode plate 19 with a second flow channel 18 oppositely arranged, from the direction from the anode plate 11 to the cathode plate 19, the anode A first gas diffusion layer 13 , a first catalyst layer 14 , a proton exchange membrane 15 , a second catalyst layer 16 and a second gas diffusion layer 17 are sequentially disposed between the plate 11 and the cathode plate 19 . For the installation positions of the above-mentioned structures, reference may be made to the prior art.

[0087] Wherein the first gas diffusion layer 13 , the second gas diffusion layer 17 , the first catalyst layer 14 and the second catalyst layer 16 are provided with convex-concave structures on opposite sides (surfaces on the left and right sides).

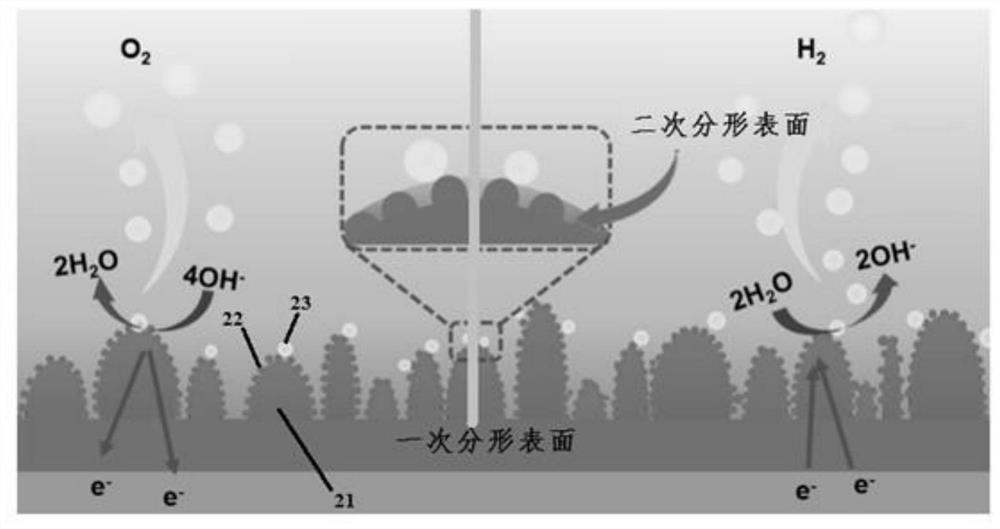

[0088] The above-mentioned convex-concave structure includes a primary fractal structure and a secondary fr...

Embodiment 2

[0092] The difference between this embodiment and embodiment 1 is mainly reflected in the following parts:

[0093] The distance between two adjacent primary protrusions 21 is 5 times the diameter of the bubbles 23 formed during the electrolysis process, and the distance between two adjacent secondary protrusions 22 is twice the diameter of the bubbles 23 formed during the electrolysis process. The diameter of the air bubbles 23 is 0.5 mm. The gas-liquid contact angle of the surface of the secondary protrusion 22 was 50°.

[0094] The first gas diffusion layer 13 is made of expanded screen, and the second gas diffusion layer 17 is made of carbon cloth. Both the first catalyst layer 14 and the second catalyst layer 16 are made of carbon-supported Ru particles.

Embodiment 3

[0096] The difference between this embodiment and embodiment 1 is mainly reflected in the following parts:

[0097] The convex-concave structure has only a first-order fractal structure, and the distance between two adjacent first-order protrusions 21 is one time of the diameter of the bubble 23 formed in the electrolysis process. The diameter of the bubble 23 is 3 mm. The gas-liquid contact angle of the surface of the primary protrusion 21 was 30°.

[0098] The first gas diffusion layer 13 is made of titanium in the form of felt, and the second gas diffusion layer 17 is made of carbon cloth. Both the first catalyst layer 14 and the second catalyst layer 16 are made of carbon-supported Ti particles. The cathode plate 19 and the anode plate 11 are made of graphite, and the inner walls of the anode plate 11 and the cathode plate 19 are provided with ultrasonic generators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com