Injection device of exhaust volute of marine gas turbine

A gas turbine and exhaust volute technology, which is applied in the direction of gas turbine devices, jet propulsion devices, turbine/propulsion device inlets, etc., can solve problems such as large ejection volume, gas turbine operation failure, and large intake pipeline structure size , to achieve the effect of reducing pressure loss, improving work efficiency and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

[0034] In order to adapt to the different operating conditions of the gas turbine, reduce the working load of the gas turbine while ensuring the cooling effect of the box body, and reduce the pressure loss of the exhaust system, the injection device is further improved in this embodiment, and the design Developed a new ejector device for the exhaust volute of marine gas turbines;

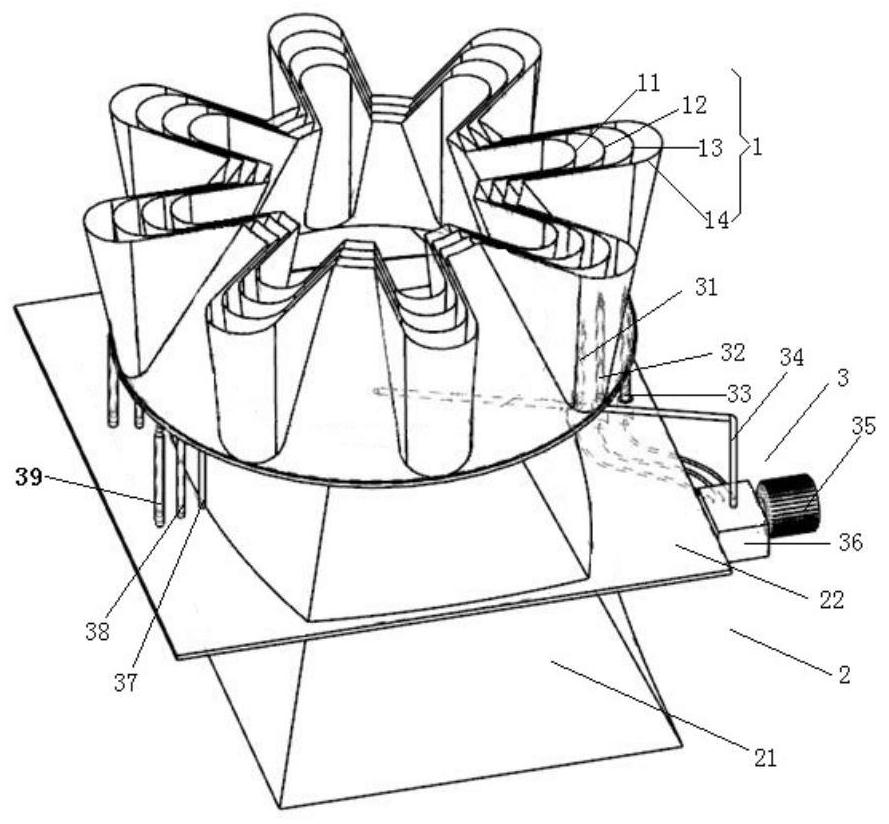

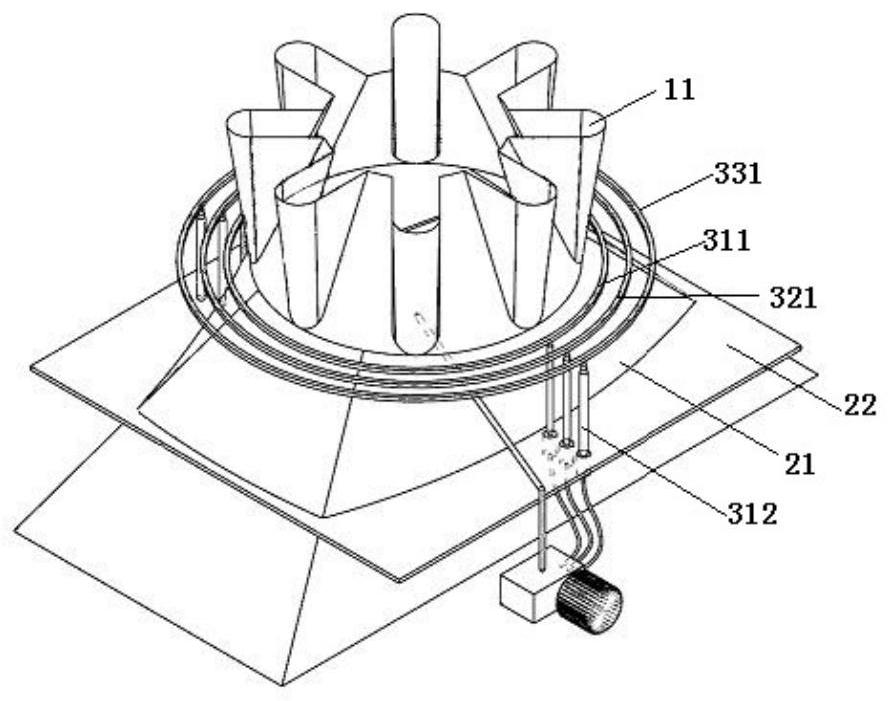

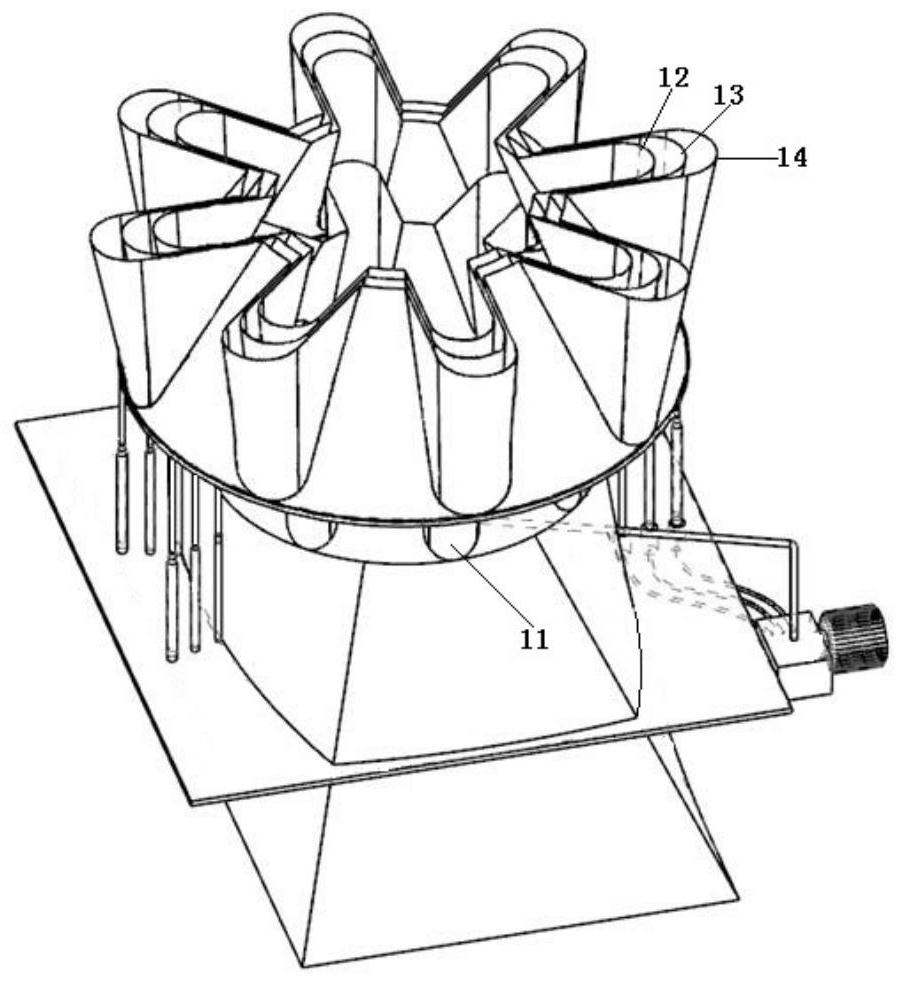

[0035] The injection device includes a multi-stage nozzle 1, a smoke export device 2 and a control module 3;

[0036] The flue gas exporting device 2 includes a square-to-ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com