Heating furnace temperature control method and system based on improved particle swarm optimization

A technology for improving particle swarm optimization and particle swarm optimization, which is applied to furnace control devices, controllers with specific characteristics, electric controllers, etc., can solve the problem of low temperature control accuracy of heating furnaces, and achieve fast optimization speed and adjustment The effect of high precision and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

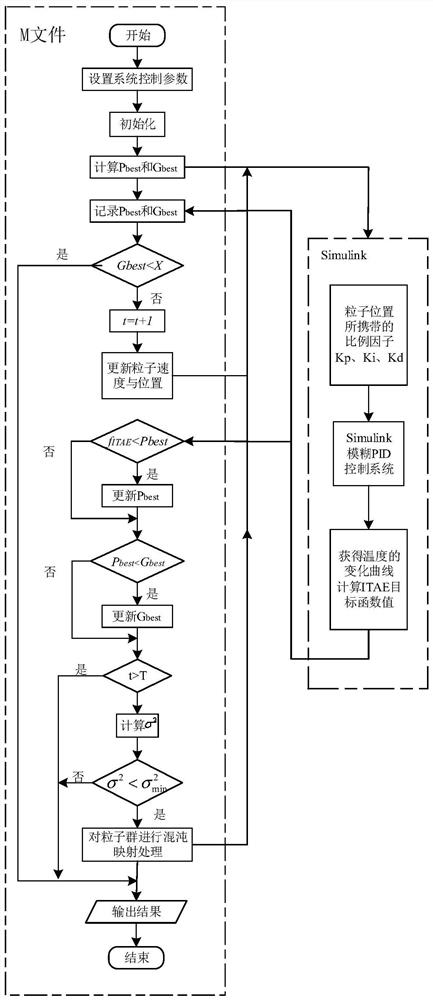

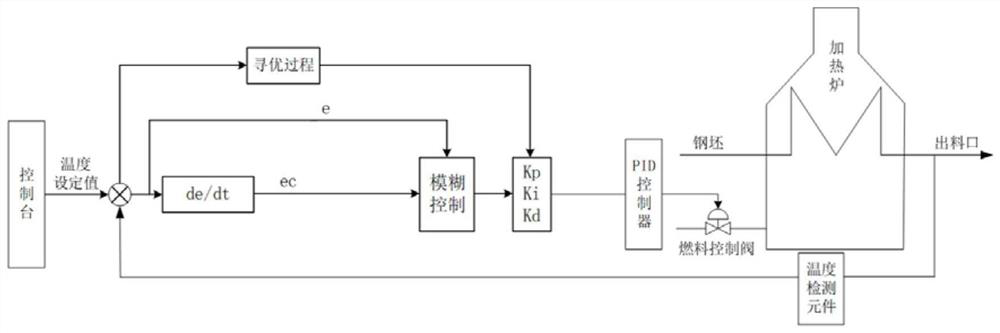

[0045] The structure of a heating furnace temperature control system based on improved particle swarm optimization fuzzy PID is as follows: image 3 As shown, including fuzzy control module, gain module, PID control module, control valve, optimization module and temperature transmission module, such as image 3 As shown in the flow chart, the input terminal of the fuzzy control module inputs the error between the outlet temperature of the heating furnace and the temperature set value, and the rate of change of the error. The signals of the fuzzy control module and the optimization module are sent to the gain module, and then sent through the gain module To the PID control module to realize the control of the control valve, the control valve controls the output temperature to the controlled object, and adjusts the furnace outlet temperature of the controlled object heating furnace; the furnace outlet temperature of the heating furnace is fed back to the input through the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com