Device for enabling wire and cable to be coated more quickly by using temperature difference

A wire and cable, differential technology, applied in conductor/cable supply device, conductor/cable insulation, cable/conductor manufacturing, etc., can solve the problems of slow drying speed and low efficiency of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

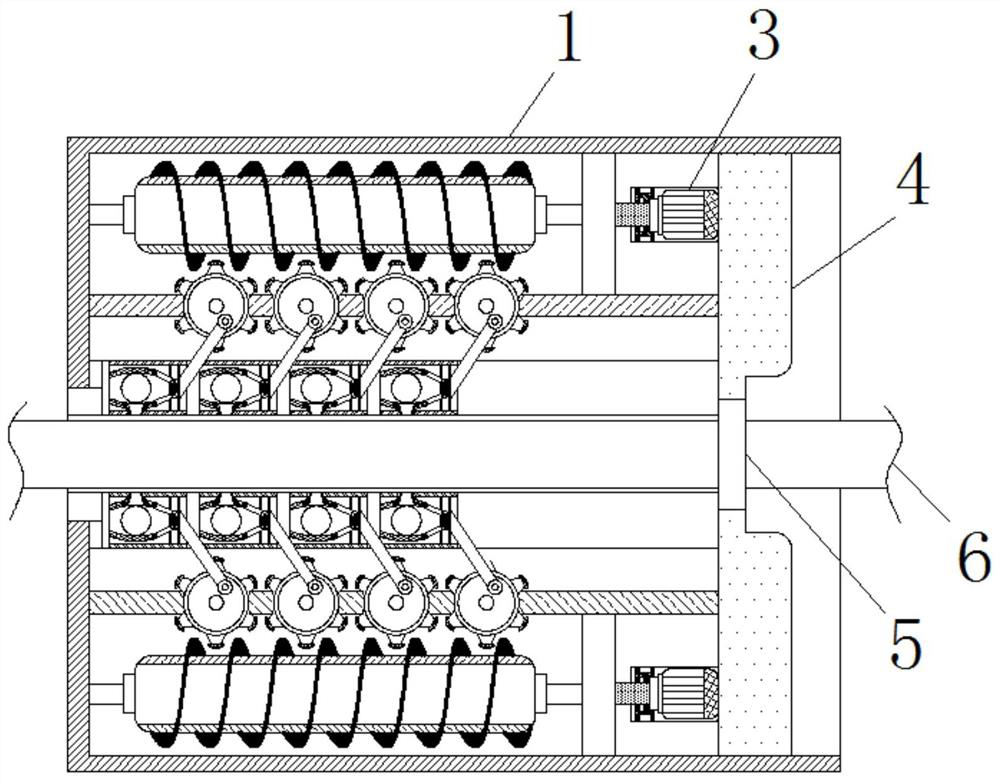

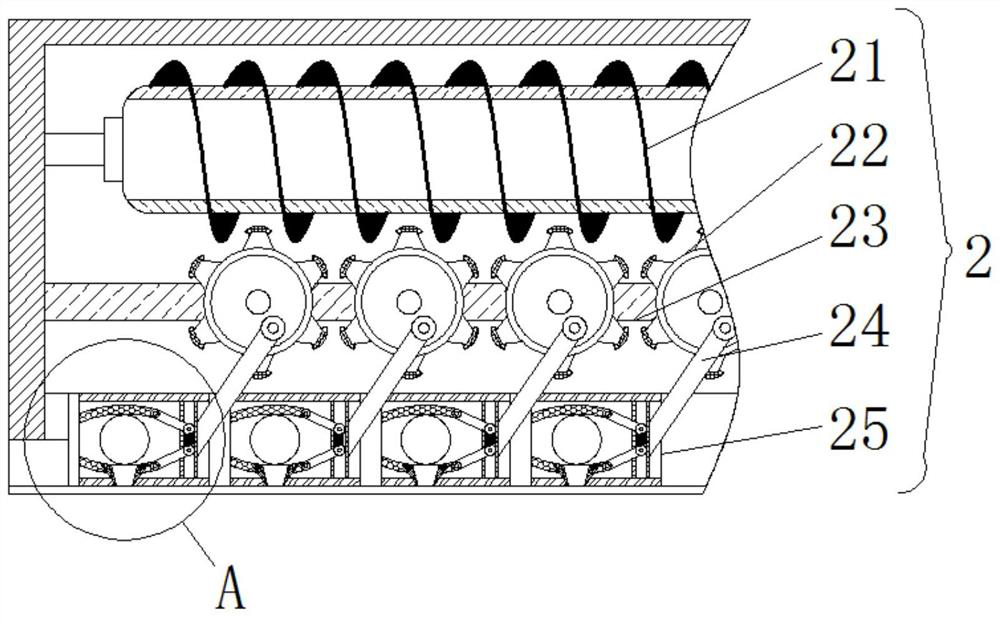

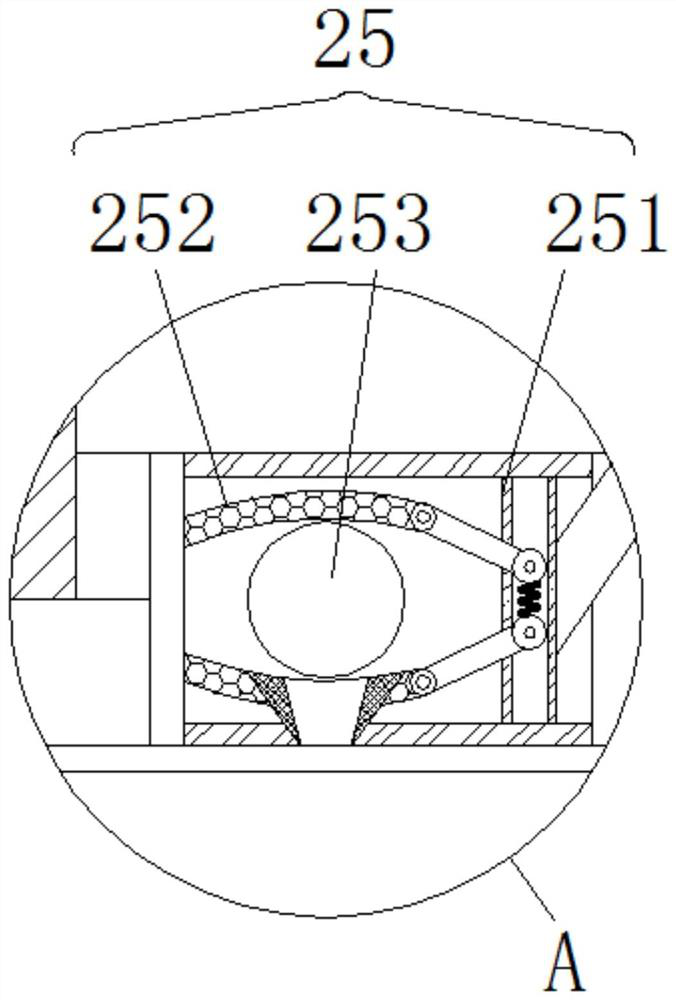

[0027] see Figure 1-3 , a device that makes use of temperature differences to make wire and cable coating faster, including a frame 1, a cooling mechanism 2 is fixedly installed at the upper and lower ends of the frame 1, and the cooling mechanism 2 includes: a rotating rod 21, and the lower end of the rotating rod 21 engages Connecting wheel 22 is connected, and connecting wheel 22 is rotatably connected on the cross plate 23, and the internal activity of connecting wheel 22 is installed with guide rod 24, and guide rod 24 is movably installed in the eccentric place of connecting wheel 22, between guide rod 24 and slide plate 251 The connection relationship between them is a movable hinge, a return spring is fixedly installed on the opposite surface of the arc ring 252 and on the inner end surface of the sliding plate 251, and the lower end of the cooling mechanism 2 is fixedly installed with a uniformly distributed connection frame 25, through the driving device 3 Drive the...

Embodiment 2

[0030] see figure 1 , 4 , a device that makes use of temperature differences to make wire and cable coating faster, including a frame 1, a cooling mechanism 2 is fixedly installed at the upper and lower ends of the frame 1, and a driving device 3 is fixedly installed at the right end of the cooling mechanism 2, and the frame 1 Inside and on the right end face of the cooling mechanism 2, a fixed plate 4 is fixedly installed, and a guide wheel 41 is fixedly installed on the fixed plate 4. The upper end of the guide wheel 41 is designed as a feed inlet, and the lower end is designed as a discharge port. The inside of the guide wheel 41 The left and right ends of the guide wheel 41 are fixedly equipped with a heating plate 42, the upper and lower ends of the guide wheel 41 are provided with a groove body 43, the upper and lower ends of the guide wheel 41 are fixedly equipped with a material trough 44, and the inside of the guide wheel 41 is fixedly installed with a channel leading...

Embodiment 3

[0033] see Figure 1-4 , a device that makes use of temperature differences to make wire and cable coating faster, including a frame 1, a cooling mechanism 2 is fixedly installed at the upper and lower ends of the frame 1, and the cooling mechanism 2 includes: a rotating rod 21, and the lower end of the rotating rod 21 engages Connecting wheel 22 is connected, and connecting wheel 22 is rotatably connected on the cross plate 23, and the internal activity of connecting wheel 22 is installed with guide rod 24, and guide rod 24 is movably installed in the eccentric place of connecting wheel 22, between guide rod 24 and slide plate 251 The connection relationship between them is a movable hinge, and a return spring is fixedly installed on the opposite surface of the arc ring 252 and on the inner end surface of the sliding plate 251, and the lower end of the cooling mechanism 2 is fixedly installed with evenly distributed connecting frames 25, and the connecting frames 25 A sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com