Preparation method of nano-aluminum powder coated with mesoporous titanium dioxide

A technology of mesoporous titanium dioxide and nano-aluminum powder, which is applied in offensive equipment, explosives processing equipment, explosives, etc., can solve problems such as unsuitable for industrial production, complex process, and small output, and achieve rapid combustion reaction, simple reaction, and The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

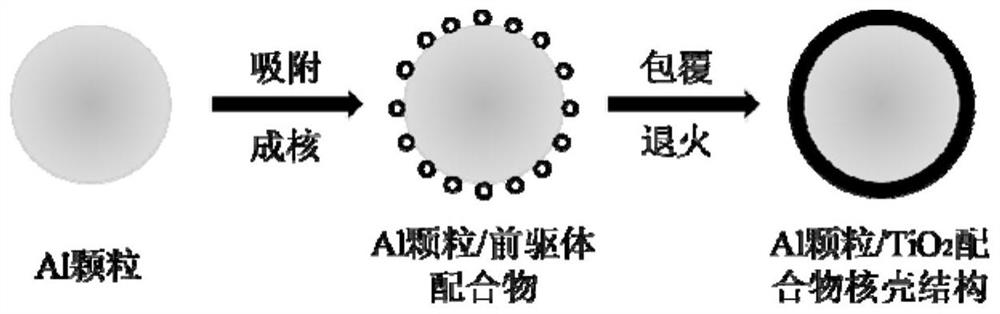

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 1.5g of triblock copolymer Pluronic F127, 2.4mL of acetic acid, and 3.2mL of concentrated hydrochloric acid in 30mL of tetrahydrofuran in sequence, and then add 3.0mL of butyl orthotitanate dropwise under stirring conditions. Place it in a blast oven at 45°C to dry, so that the solvent is completely evaporated, and the solidified mesoporous TiO is obtained. 2 Precursor gel.

[0028] Weigh 3.0g of the precursor gel and add it to 15mL of absolute ethanol and stir evenly, then add 3mL of glycerol dropwise, disperse 0.1g of nano-aluminum powder in the solution, stir and react in an oil bath at 100°C for 6h, and collect the product by centrifugation after cooling , washed, vacuum dried, and finally annealed for 3h under vacuum or inert gas conditions to obtain mesoporous TiO 2 Coated with nano-aluminum powder.

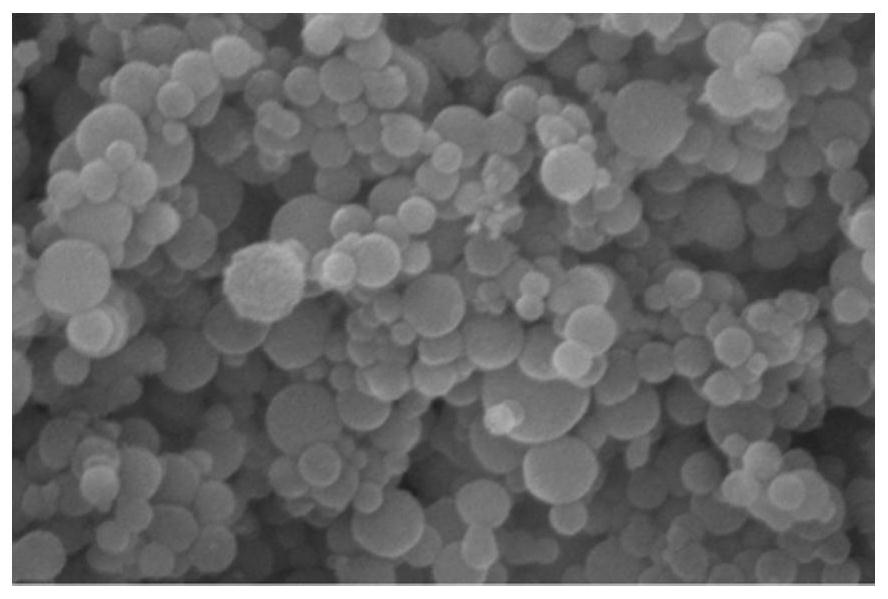

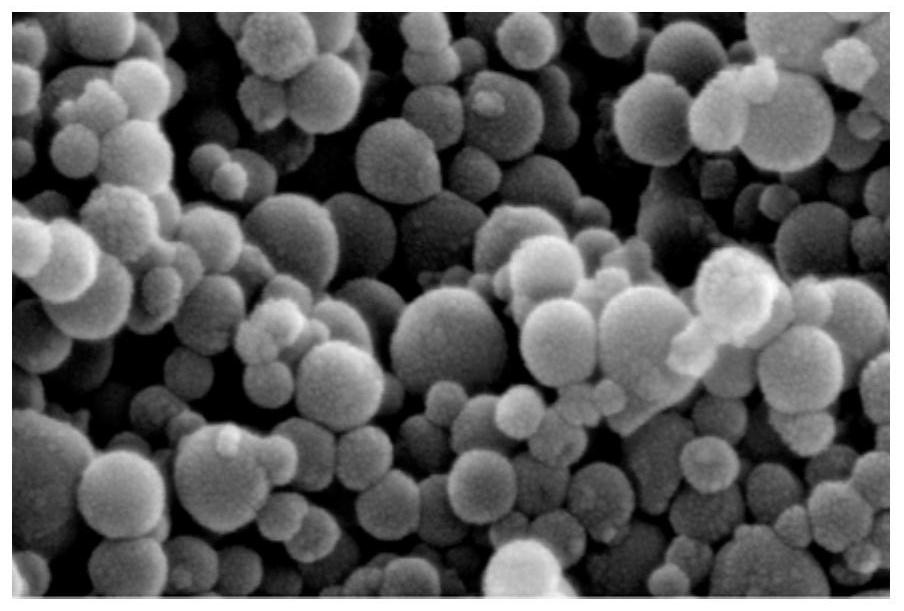

[0029] image 3 and Figure 5 These are the SEM and TEM photos of the metal oxide-coated nano-aluminum powder prepared in this example, respectively. It...

Embodiment 2

[0031] Dissolve 1.5g of triblock copolymer Pluronic F127 and 5mL of concentrated hydrochloric acid in 30mL of isopropanol in sequence, then add 3.0mL of butyl orthotitanate drop by drop under stirring condition, after stirring evenly, place it in 45 ℃ drying in a blast oven to completely volatilize the solvent to obtain solidified mesoporous TiO 2 Precursor gel.

[0032] Weigh 3.0g of the precursor gel and add it to 15mL of absolute ethanol and stir evenly, then add 8mL of glycerol dropwise, disperse 0.1g of nano-aluminum powder in the solution, stir and react in an oil bath at 100°C for 4h, and collect the product by centrifugation after cooling , washed, vacuum dried, and finally annealed for 3h under vacuum or inert gas conditions to obtain mesoporous TiO 2 Coated with nano-aluminum powder.

Embodiment 3

[0034] Dissolve 2.0g of triblock copolymer Pluronic F127 and 6.4mL of glacial acetic acid in 30mL of tetrahydrofuran in sequence, then add 4.0mL of ethyl orthotitanate dropwise under stirring conditions, stir well, and place it at 45°C Dry in a blast oven to completely volatilize the solvent to obtain solidified mesoporous TiO 2 Precursor gel.

[0035] Weigh 2.0g of the precursor gel and add it to 10mL of absolute ethanol and stir evenly, then drop 5mL of glycerol to disperse 0.3g of nano-aluminum powder in the solution, stir and react in an oil bath at 100°C for 18h, and collect the product by centrifugation after cooling. Washing, vacuum drying, and finally annealing for 3h under vacuum or inert gas conditions to obtain mesoporous TiO 2 Coated with nano-aluminum powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com