Method for preparing optical fiber mirror by ultrasonic fusion coating on optical fiber end face

An optical fiber end face, ultrasonic technology, applied in cladding optical fiber, optical waveguide light guide, coating, etc., can solve the problems of reflective mirror displacement, large curing stress, coating layer cracks, etc., and achieve simple coating process and high coating quality , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

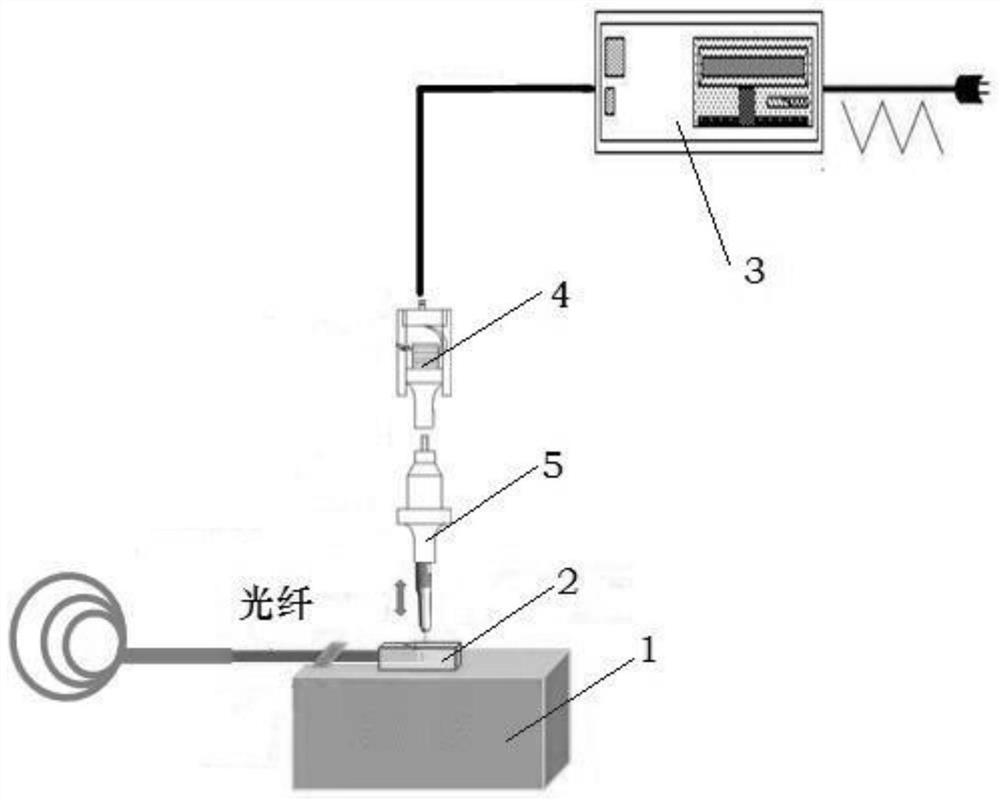

[0017] Such as figure 1 As shown, a kind of fusion coating system for optical fiber reflector includes a heating platform 1 and an ultrasonic system. The heating platform 1 is provided with a Teflon rectangular groove 2. The ultrasonic system includes a high-frequency power supply 3 connected to a pressure-based The transducer 4 of the electric ceramic crystal, the output end of the transducer 4 is connected with a temperature-adjustable ultrasonic welding head 5 .

[0018] A method for preparing an optical fiber mirror by ultrasonic fusion coating on the end face of an optical fiber, comprising the following steps:

[0019] Take the single-mode optical fiber, remove the acrylate coating on the surface, wipe it with a dust-free paper dipped in alcohol, and cut it with an optical fiber cutter to obtain a flat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com