Liquid composition, ferroelectric insulation sheet, and method for producing same

A technology of composition and insulating sheet, applied in insulators, insulators, organic insulators, etc., can solve the problems of brittleness and low flexibility, and achieve the effect of high flexibility and high uniform dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

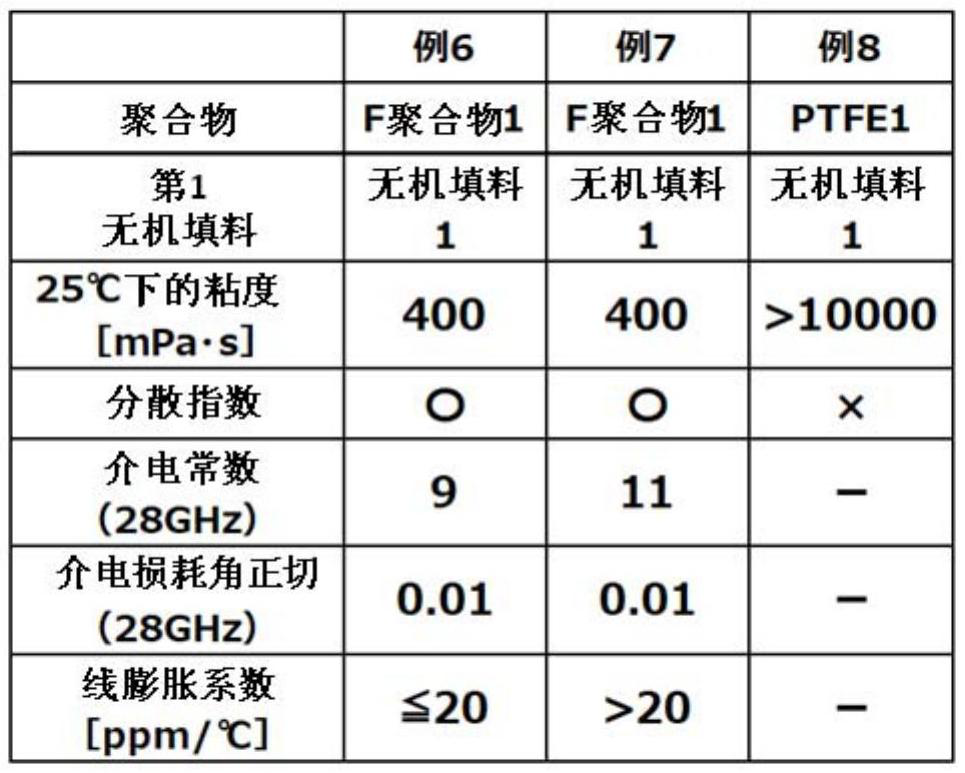

[0179] Example

[0180] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples.

[0181] 1. Preparation of Components and Components

[0182] [polymer]

[0183] F Polymer 1: A copolymer containing TFE-based units, NAH-based units, and PPVE-based units in the order of 98.0 mol%, 0.1 mol%, and 1.9 mol% (melting temperature: 300°C, melting temperature at 380°C Viscosity: 3×10 5 Pa s)

[0184] F Polymer 2: A copolymer without functional groups containing TFE-based units and PPVE-based units in the order of 97.5 mol% and 2.5 mol% (melting temperature: 305°C, melt viscosity at 380°C: 3×10 5 Pa s)

[0185] PTFE1: Homopolymer of TFE (melting temperature: 327°C, melt viscosity at 380°C: 2×10 9 Pa·s or above)

[0186] PVDF1: Solvent-soluble polyvinylidene fluoride

[0187] [powder]

[0188] F powder 1: powder composed of F polymer 1 with an average particle size of 2.6 μm

[0189] F powder 2: powder composed of ...

Example

[0199] (example 1)

[0200] After the N-methyl-2-pyrrolidone (NMP) of 38.5 mass parts, the nonionic fluorinated polyhydric alcohol of 1.5 mass parts, the F powder 1 of 30 mass parts, and the inorganic filler 1 of 30 mass parts are dropped in the tank, Put zirconia balls into the tank. Thereafter, the tank was rolled at 150 rpm for 1 hour to disperse F powder 1 and inorganic filler 1 in NMP to prepare dispersion 1.

[0201] Thereafter, the dispersion liquid 1 is coated on the surface of the metal foil 1 by a die coating method in a roll-to-roll manner to form a wet film. Thereafter, the metal foil 1 on which the wet film was formed was passed through a drying oven at 140° C. for 5 minutes, and dried by heating. Thereafter, the dried film was heated and fired at 380° C. for 10 minutes in a nitrogen furnace. Thereby, the laminated body 1 in which the FE sheet was formed on the surface of the metal foil 1 was produced. In addition, the thickness of the FE sheet was 50 μm.

Example

[0202] (Example 2)

[0203] Except having changed the inorganic filler 1 into the inorganic filler 2, the dispersion liquid 2 was prepared similarly to Example 1, and the laminated body 2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com