Passive Mechanical Screwing Device

A passive, mechanical technology, applied in the field of machinery, can solve the problems of time-consuming repetitive disassembly and assembly operations, difficulty in ensuring operation accuracy, and remote operation errors, and achieve the effects of improving convenience, versatility, and reducing power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

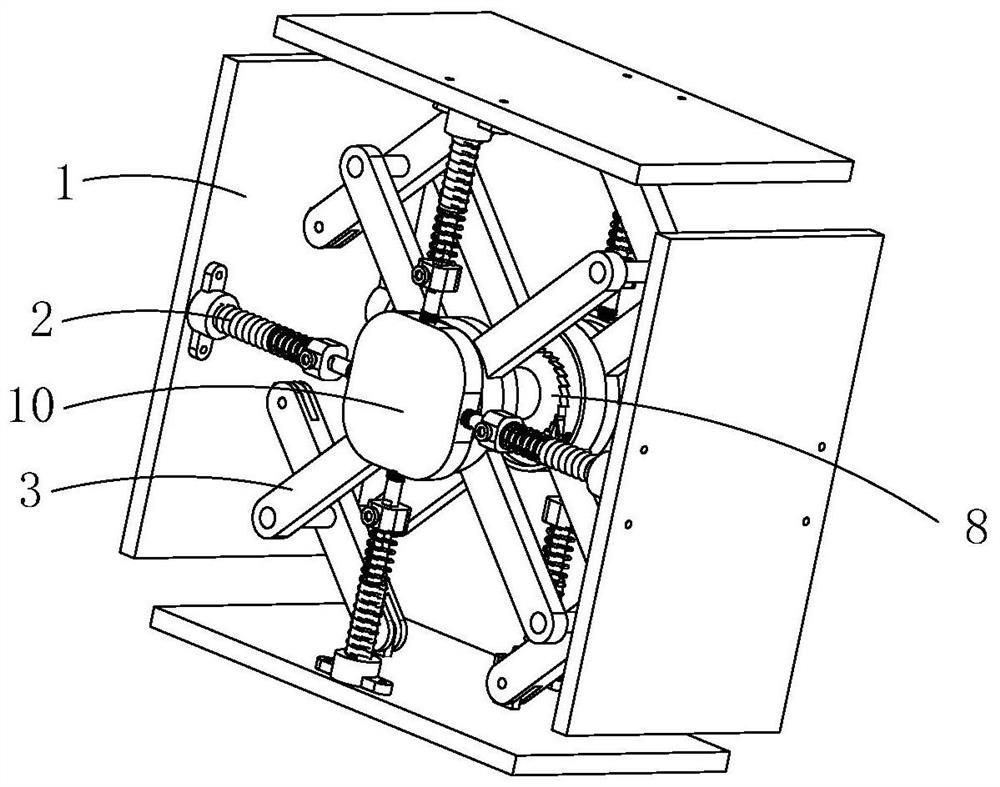

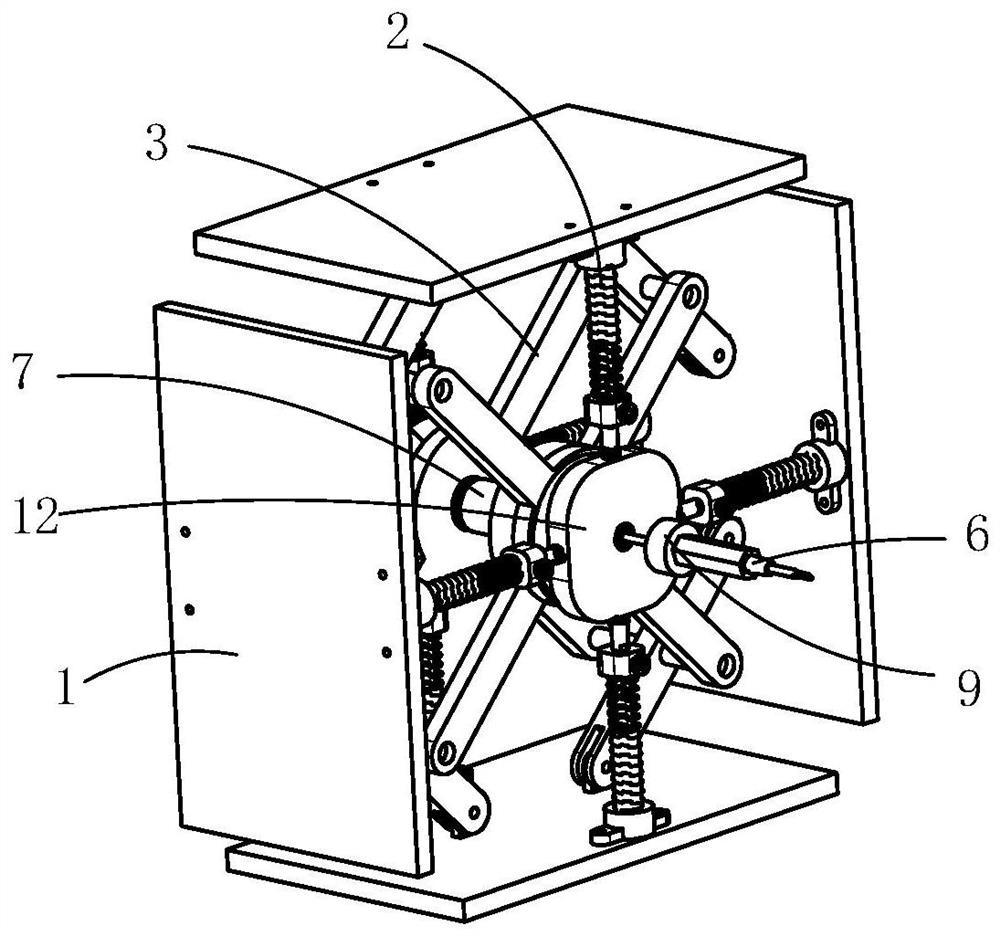

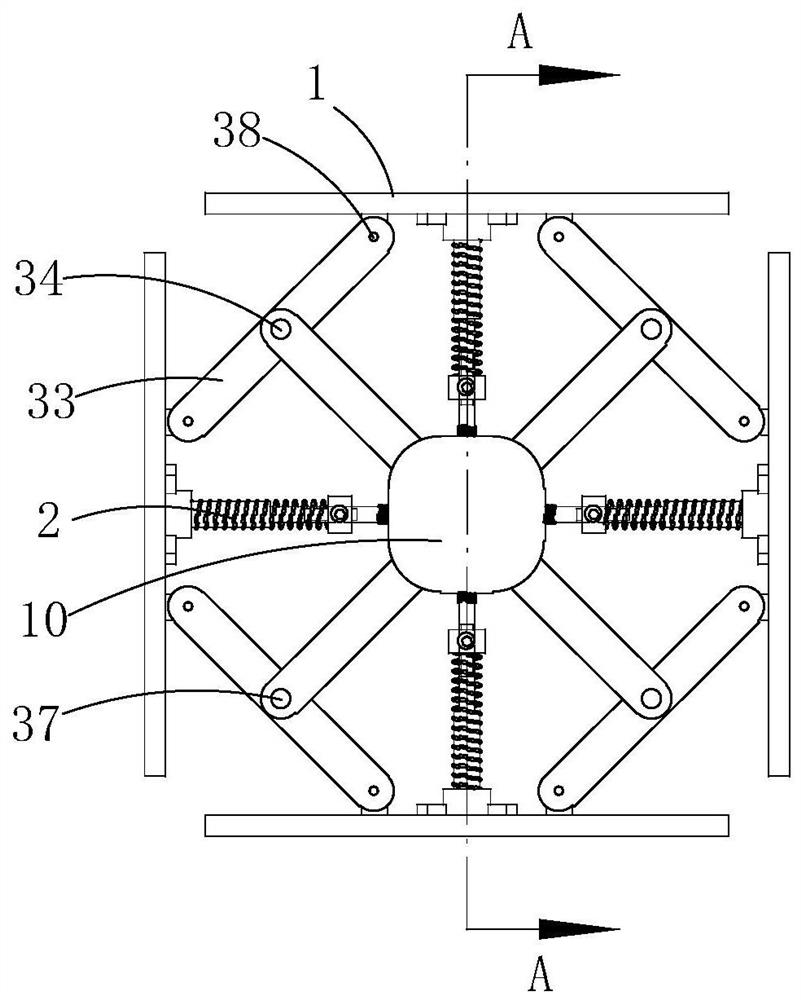

[0036] Please also refer to Figure 1 to Figure 18Now, the passive bidirectional mechanical screwing device provided by the present invention will be described. The passive mechanical screwing device includes four pressing plates 1, a first ratchet transmission mechanism 5, a second ratchet transmission mechanism 8, a multi-link mechanism 3, a planetary gear 42, an acceleration mechanism 4, multiple groups of elastic guide mechanisms and screwing Beat head 6, four pressing plates 1 are parallel to form a rectangular frame in pairs.

[0037] The first ratchet tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com