Mechanical manufacturing clamp

A technology of mechanical manufacturing and fixtures, which is applied in the field of mechanical manufacturing fixtures. It can solve the problems of large machining errors in the middle, affecting the accuracy of machining, and inconvenient adjustment of the main fixture, so as to achieve the effects of reducing errors, increasing friction, and reducing the number of times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

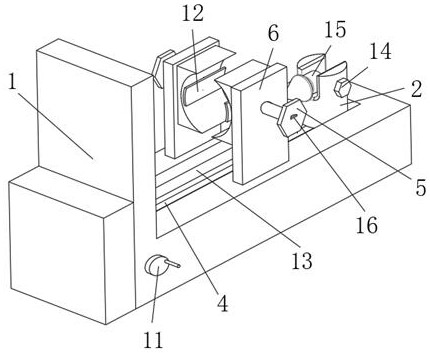

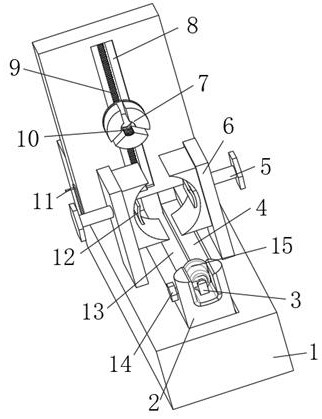

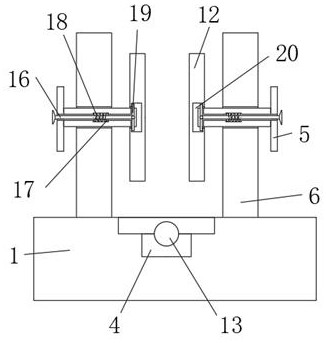

[0022] see Figure 1-5 , the present invention provides the following technical solutions: a fixture for mechanical manufacturing, including a main body 1, an adjustment block 2 and a support block 6, the main body 1 is provided with a sliding groove 8 for the rotation of the rack mechanism 9, and the sliding groove 8 is provided for The rotating shaft connected with the rocker 11, the rotating shaft of the sliding groove 8 is provided with a second gear mechanism 24 for connecting with the rack mechanism 9, the second gear mechanism 24 is connected with the main clamp 7 through the rack mechanism 9, the main body 1 There is a moving groove 4 for adjusting the moving effect of the adjusting block 2 inside. The moving groove 4 is provided with a screw rod 13 for adjusting the function of the adjusting block 2. The moving groove 4 is connected with the adjusting block 2 through the screw rod 13. The adjusting block 2 is provided with There is a rectangular slot for the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com