Numerical control machine tool cutter remaining service life prediction method and system and application

A CNC machine tool and life prediction technology, applied in the field of machinery, can solve problems such as poor generalization ability of prediction models, achieve the effect of improving generalization ability, customer service limitations, and improving model prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

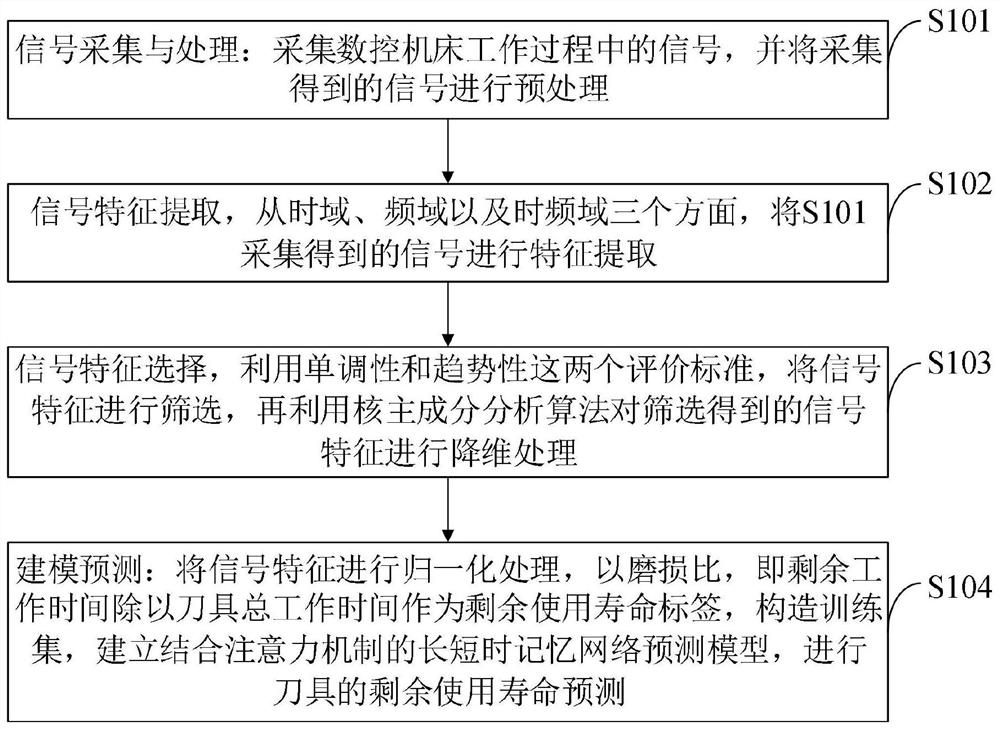

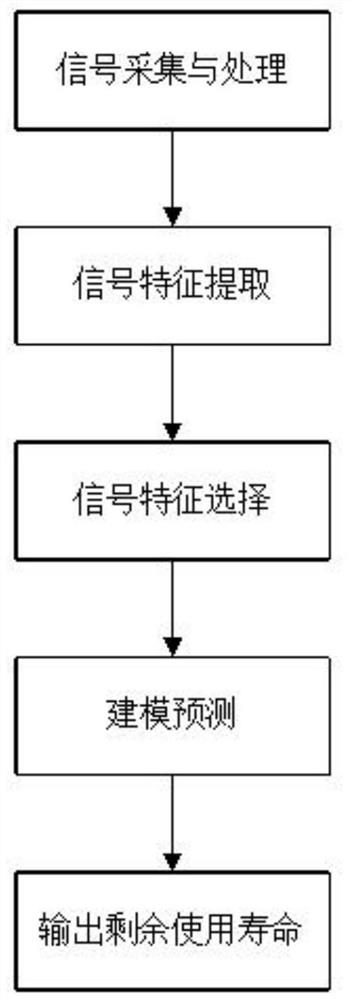

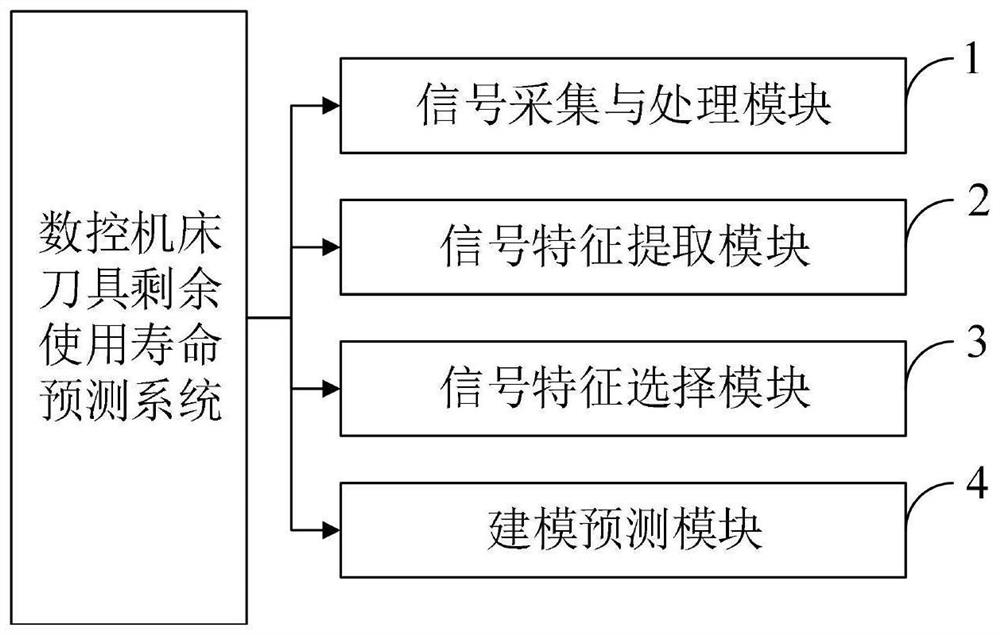

[0079] refer to figure 2 , the steps for realizing the present invention will be further described in detail.

[0080] Step 1, signal acquisition and processing.

[0081] The first step is to collect the signals during the working process of the CNC machine tool, that is, the controller signal and the sensor signal. The controller signal mainly includes the spindle load and the mechanical coordinates in three directions, namely the x-axis mechanical coordinates, y-axis mechanical coordinates and z-axis mechanical coordinates , the sensor signal mainly includes the current signal and the vibration signal in three directions, that is, the vibration signal in the x-axis direction, the vibration signal in the y-axis direction, the vibration signal in the z-axis direction and the current signal.

[0082] The second step is to preprocess the collected signals. First, the signals collected when not in contact with the processing object are eliminated according to the mechanical coo...

Embodiment 2

[0105] The data set used in the embodiment of the present invention is the Foxconn machining tool data in the second industrial big data innovation competition. The data is collected from the real machining process of the CNC machine tool. A brand new tool is normally processed from the beginning to the end of the tool life. Stop collecting.

[0106] 1) Signal acquisition and processing.

[0107]1.1) Collect the signals during the working process of the CNC machine tool, that is, the controller signal and the sensor signal. The controller signal mainly includes the spindle load and the mechanical coordinates in three directions, namely the x-axis mechanical coordinate, the y-axis mechanical coordinate and the z-axis mechanical coordinate. The sensor The signals mainly include current signals and vibration signals in three directions, namely, vibration signals in the x-axis direction, vibration signals in the y-axis direction, vibration signals in the z-axis direction, and curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com