Full-temperature-range pressure swing adsorption method for removal and recovery of organic tail gas containing different concentrations of VOCs (volatile organic compounds)

A pressure swing adsorption, full temperature range technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the environmental health problems that cannot effectively solve the removal of VOCs, uneven component content, insufficient treatment depth, etc. problems, to achieve the effect of reducing investment and energy consumption, low energy consumption and cost, and solving high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

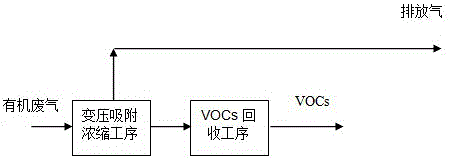

[0033] like figure 1 As shown, the full temperature range pressure swing adsorption method for the removal and recovery of organic tail gas containing different concentrations of VOCs, the steps of the method are as follows:

[0034] (1) Pressure swing adsorption concentration process;

[0035] a. It is carried out in a pressure swing adsorption system. The pressure swing adsorption system consists of 4 adsorption towers, of which 1 to 3 adsorption towers are in the adsorption state, and the remaining adsorption towers are in the regeneration state. One or more of aluminum, molecular sieve, and desulfurizer; one or more adsorption towers into which the organic tail gas is passed for adsorption at the bottom, the adsorption pressure is 0.1~0.3Mpag, and the operating temperature is 60~80℃; multiple adsorption towers Alternate cycle operation to ensure continuous entry of organic tail gas;

[0036] b. The unadsorbed tail gas is discharged from the top of the adsorption tower. W...

Embodiment 2

[0044] like figure 1 As shown, the full temperature range pressure swing adsorption method for the removal and recovery of organic tail gas containing different concentrations of VOCs, the steps of the method are as follows:

[0045] (1) Pressure swing adsorption concentration process;

[0046] d. It is carried out in a pressure swing adsorption system. The pressure swing adsorption system consists of 8 adsorption towers, of which 1 to 7 adsorption towers are in the adsorption state, and the rest of the adsorption towers are in the regeneration state. One or more of aluminum, molecular sieve, and desulfurizer; one or more adsorption towers into which the organic tail gas is passed for adsorption at the bottom, the adsorption pressure is 0.3~0.4Mpag, and the operating temperature is 80~110℃; multiple adsorption towers Alternate cycle operation to ensure continuous entry of organic tail gas;

[0047] e. The unadsorbed tail gas is discharged from the top of the adsorption tower...

Embodiment 3

[0055] like figure 1 As shown, the full temperature range pressure swing adsorption method for the removal and recovery of organic tail gas containing different concentrations of VOCs, the steps of the method are as follows:

[0056] (1) Pressure swing adsorption concentration process;

[0057] a. It is carried out in a pressure swing adsorption system. The pressure swing adsorption system consists of 10 adsorption towers, of which 1 to 9 adsorption towers are in the adsorption state, and the rest of the adsorption towers are in the regeneration state. One or more of aluminum, molecular sieve and desulfurizer; one or more adsorption towers into which the organic tail gas is passed for adsorption at the bottom, the adsorption pressure is 0.5~0.6Mpag, and the operating temperature is 120~150℃; multiple adsorption towers Alternate cycle operation to ensure continuous entry of organic tail gas;

[0058] b. The unadsorbed tail gas is discharged from the top of the adsorption towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com