Yarn embedded type multilayer non-woven fabric structure and manufacturing equipment thereof

A technology for non-woven fabrics and manufacturing equipment, applied in the field of non-woven fabrics, can solve problems such as hindering the promotion of functional non-woven materials, inability to apply special functional materials for compounding, and insufficient performance, achieving simple structure and high cost utilization rate. , Reliability and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

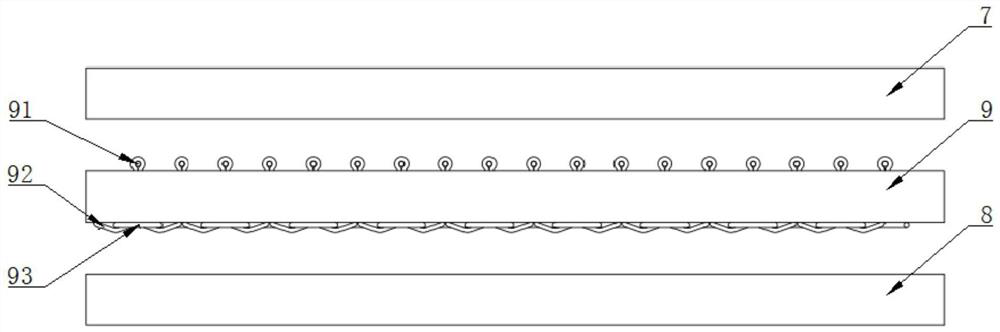

[0040] Such as figure 1 As shown, a yarn-embedded multi-layer nonwoven fabric structure includes an upper layer of fiber web 7 and a lower layer of fiber web 8, and an embedded yarn fiber web layer is arranged between the upper layer of fiber web 7 and the lower layer of fiber web 9 9: The upper layer fiber web 7, the middle layer fiber web 8 and the embedded yarn fiber web layer 9 form a multi-layer composite structure by needling.

[0041] Wherein, the embedded yarn fiber web layer 9 is made by embedding process by warp thread 91, upper weft thread 92 and lower weft thread 93 of special material and nonwoven fiber web,

[0042] Optionally, the embedded warp threads 91 , the upper layer weft threads 92 and the lower layer weft threads 93 are selected as metal yarns, so that the composite nonwoven fabric can obtain electromagnetic shielding performance.

[0043] The embedded warp 91, the upper weft 92 and the lower weft 93 may also use other high-strength yarns to improve the...

Embodiment 2

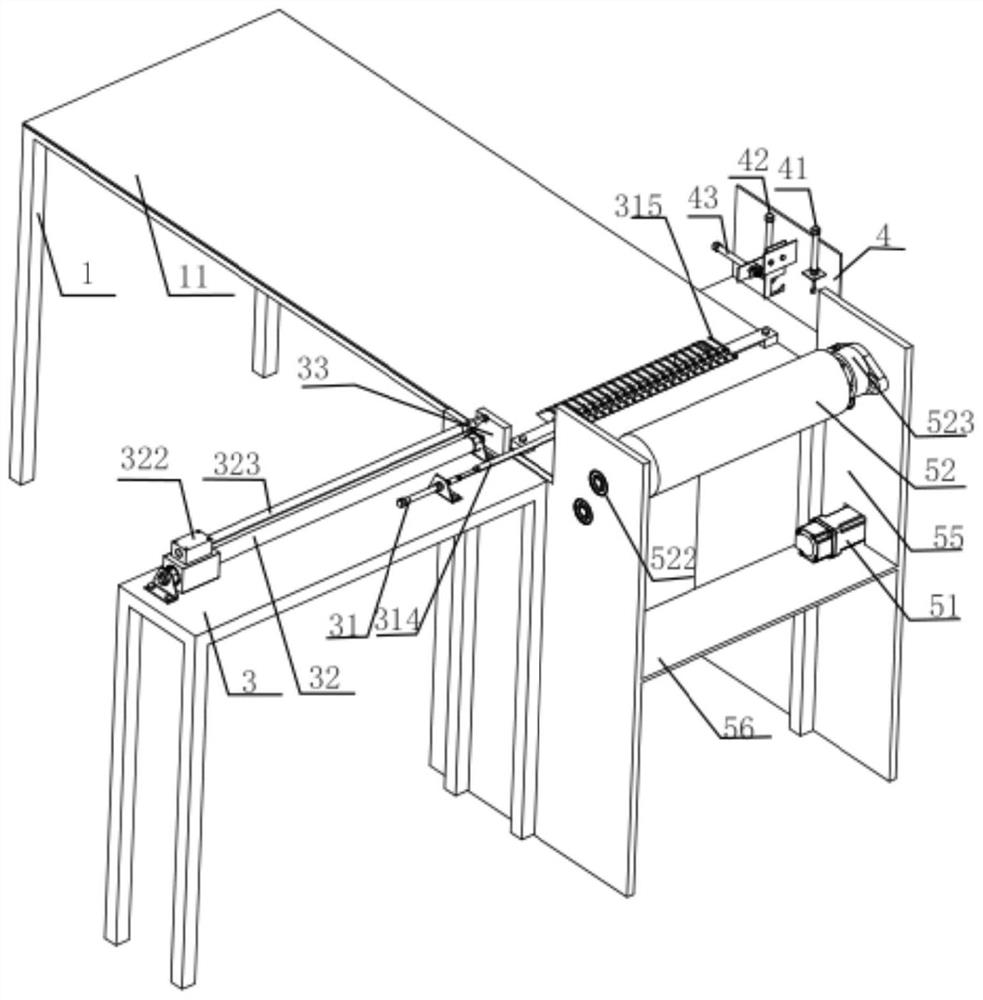

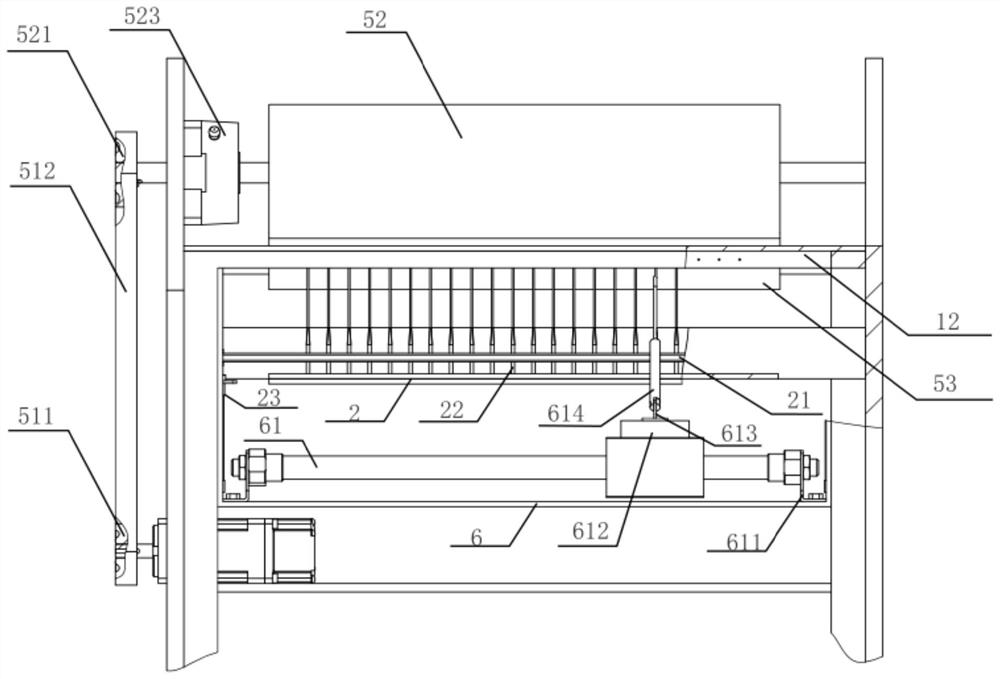

[0046] Such as Figure 2-10 As shown, this embodiment discloses a manufacturing device for a yarn-embedded multi-layer nonwoven fabric structure, including a No. 1 support 1, and a backing plate 11 with a rectangular notch is arranged on the No. 1 support 1. The pad The bottom of the front end of the plate 11 is provided with a knitting needle mechanism and a wire mechanism; one side of the front end of the No. 1 support 1 is provided with a No. 3 support 4, and the No. 3 support 4 is provided with a hooking mechanism and a thread clamping mechanism; The other side of the front end of No. 1 bracket 4 is provided with a bracket mechanism;

[0047] Along the conveying direction of the fiber web, a driving mechanism is provided at the rear end of the crochet mechanism, and the driving mechanism drives the fiber web to move forward for a predetermined distance after each threading process is completed;

[0048] The needle mechanism includes No. 1 needle bed 2 and No. 2 needle bed...

Embodiment 3

[0060] Such as Figure 11 As shown, the structure of this embodiment is substantially the same as that of Embodiment 2, except that a No. 3 needle bed 26 is arranged below the backing plate 11, and the knitting needles 22 of the No. 3 needle bed 26 are perpendicular to the pad. The plate 11 is placed on a plane, and the No. 1 cylinder 23 and the No. 2 cylinder 25 are fixedly installed on both sides of the No. 3 needle bed 26 . That is, in this embodiment, compared with Embodiment 2, the small electromagnet device 24 and the first needle bed 2 disposed on the side of the second needle bed 21 and corresponding to the needle groove holes of the second needle bed 21 are omitted.

[0061] The working principle of this embodiment is initial preparation: warp yarn 91 passes through knitting needle 22 and is introduced into the guide plate, and the nonwoven fabric is placed between the backing plate 11 plane and the hooker 315, and one side thereof is connected with the large and smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com