Ultra-thick coal seam fully-mechanized caving filling mining method based on underground gangue heap

A technology of extra-thick coal seam and mining method, applied in the fields of backfill, underground mining, special mining, etc., can solve the problems of top coal caving and goaf filling, etc., so as to improve the recovery rate, save ground space, and improve coal mining. The effect of gangue pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a fully mechanized caving and filling mining method for extra-thick coal seams based on gangue piles underground, which specifically includes the following steps:

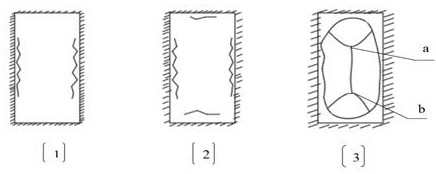

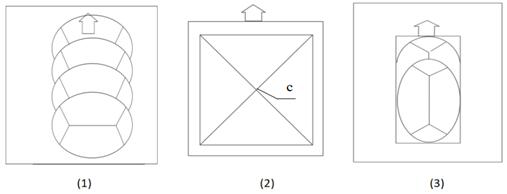

[0041] 1. Collect relevant data, according to the distribution of the overlying strata in the mine, the thickness of the coal seam, and the geological structure, the direct roof is a hard rock stratum. The length of the arranged working face is 150-200m, and the continuous advancing length of the mine working face is 1000-2000m. According to the layout of the working face and the properties of the overlying roof, the fracture form of the roof is predicted. When the length b of the working face and the advancing distance a satisfy a / b image 3 The broken form shown in (1).

[0042] 2. When arranging the coal mining face 7, based on the roof slab failure theory combined with the layout of the working face to predict the roof failure mode and the stress concentration area of the roof, i...

Embodiment 2

[0049] This embodiment provides a fully mechanized caving and filling mining method for extra-thick coal seams based on gangue piles underground, which specifically includes the following steps:

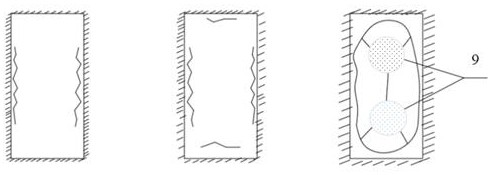

[0050] 1. Collect relevant data, according to the distribution of the overlying strata in the mine, the thickness of the coal seam, and the geological structure, the direct roof is a hard rock stratum. The length of the arranged working face is 150-200m, and the continuous advancing length of the mine working face is 1000-2000m. According to the layout of the working face and the properties of the overlying roof, the fracture form of the roof is predicted. When the length b of the working face and the advancing distance a satisfy a / b=1, basically breaking of the top image 3 (2) shows the broken form.

[0051] 2. When arranging the coal mining face 7, based on the roof failure theory combined with the layout of the working face to predict the failure mode of the roof and the stress ...

Embodiment 3

[0057] According to the layout of the working face and the properties of the overlying roof, the fracture form of the roof is predicted. When the length b of the working face and the advancing distance a satisfy a / b=1, the fracture of the basic roof is image 3 (3) The broken form shown. The steps in this embodiment are the same as those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com