Electromechanical integrated planetary speed regulation device capable of regulating speed in full range

A speed regulating device, a full range of technology, applied in the direction of electromechanical devices, transmission devices, transmission device control, etc., can solve the problems of low speed, unfavorable deep peak regulation of generator sets, low output, etc., to reduce input power and facilitate flexible start-up. The effect of stopping and improving the efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

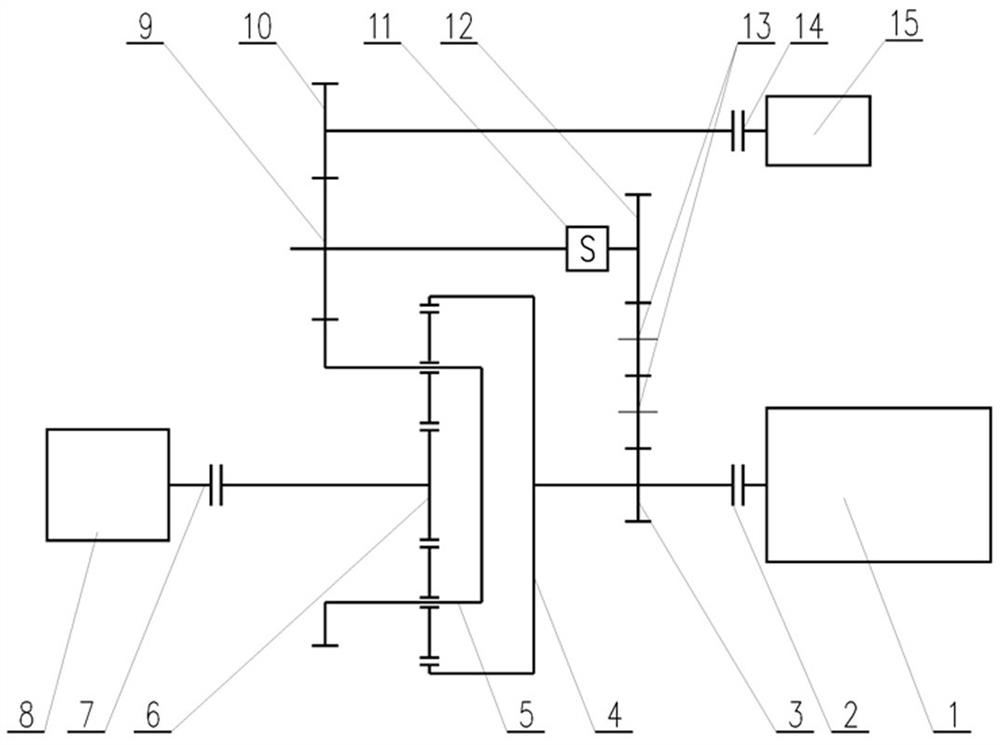

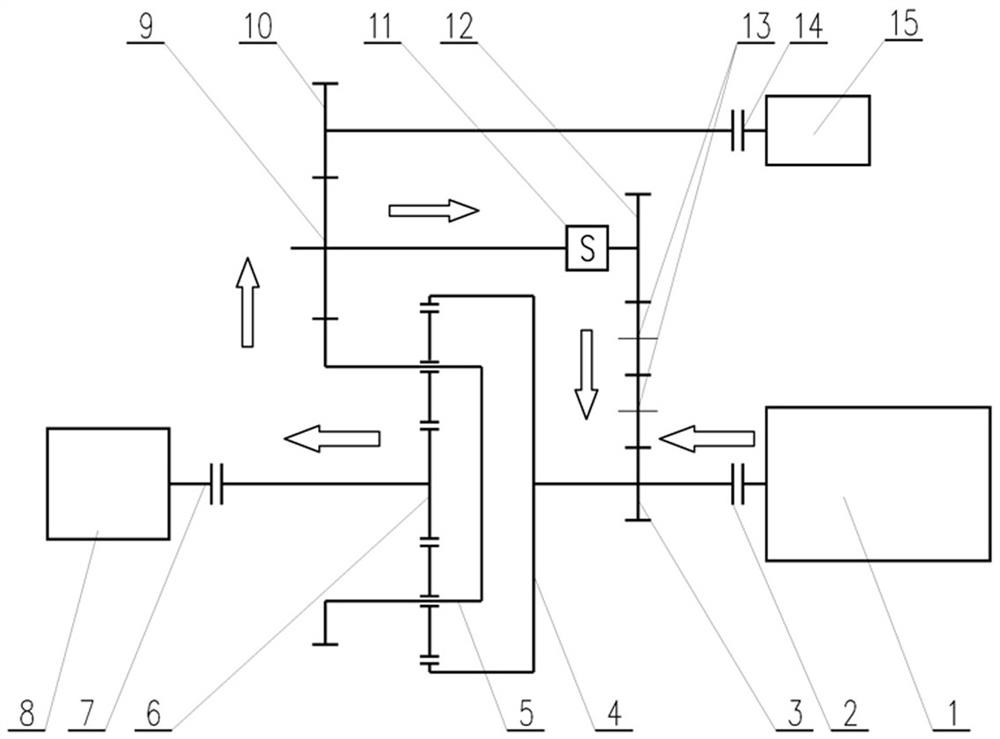

[0033]Embodiment 1: A mechatronic planetary speed control device with full-range speed regulation, which is applied to a boiler feed water pump in a power station as an example, includes a main drive motor 1, a main drive end coupling 2, a main drive end gear 3, an inner Ring gear 4, planetary carrier 5, sun gear 6, output coupling 7, feed water pump 8, speed regulating end idler gear 9, speed regulating end gear 10, synchronous automatic clutch 11, clutch output end gear 12, clutch output end Two-stage idler gear 13, speed regulating end coupling 14, speed regulating motor 15, the connection method is as follows figure 1 As shown, among them, the inner ring gear 4, the planetary carrier 5, and the sun gear 6 form a differential planetary mechanism, the speed-regulating end idler gear 9, the speed-regulating end gear 10 and the planetary carrier 5 form a speed-regulating mechanism for a differential planetary planet, and the speed-regulating End idler gear 9, synchronous autom...

Embodiment 2

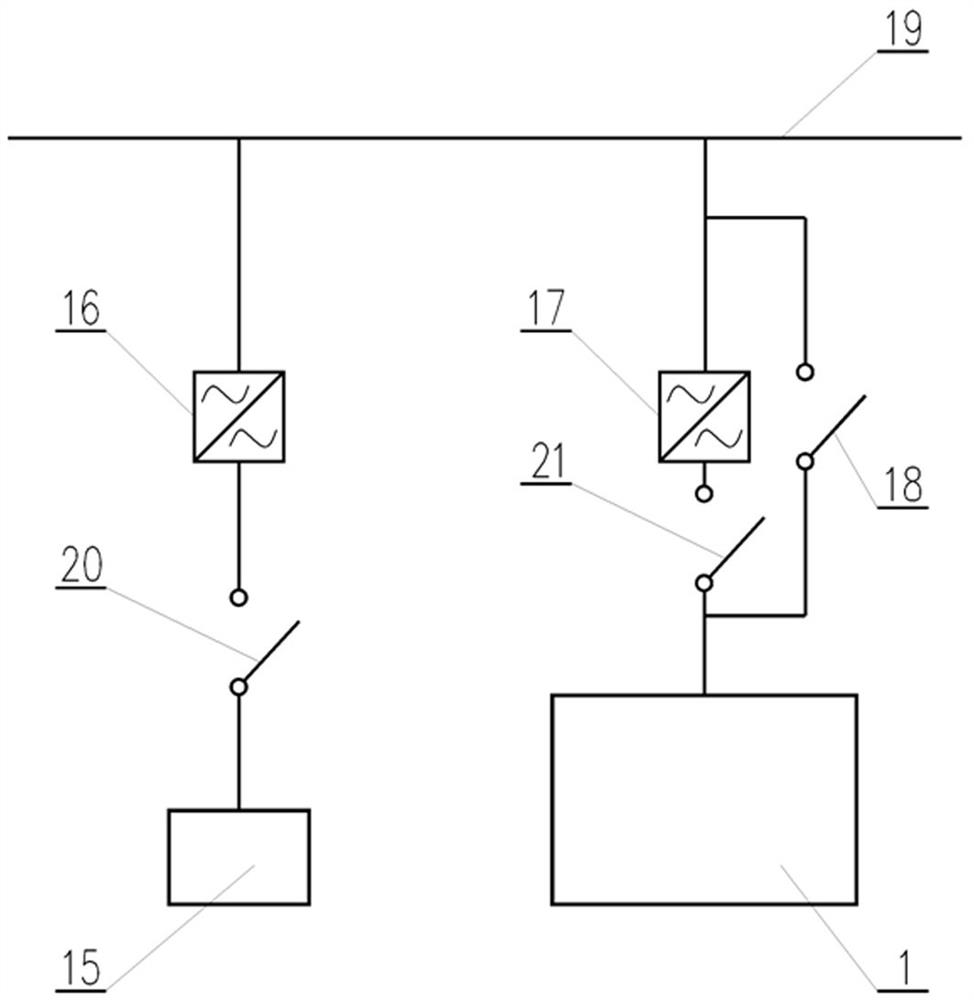

[0039] Embodiment 2: A mechatronic planetary speed regulating device with full range speed regulation. The difference from Embodiment 1 is that the main drive motor 1, the speed regulating motor 15, the four-quadrant frequency converter 16, the bypass switch 18, the factory Power consumption system 19, speed regulating motor switch 20, main drive motor switch 21, the connection method is as follows Figure 5 Shown, all the other are identical with embodiment 1.

[0040] When the capacity and voltage level of the four-quadrant frequency converter 16 in Embodiment 1 are greater than the two-quadrant frequency converter 17, or the capacity and voltage level of the four-quadrant frequency converter 16 and the two-quadrant frequency converter 17 are similar, then the four-quadrant frequency converter 16 The selection capacity and the voltage level are the larger, so that it can meet the needs of the two-quadrant frequency converter 17 at the same time, so that only the four-quadran...

Embodiment 3

[0045] Embodiment 3: A mechatronic planetary speed regulating device with full-range speed regulation. The difference from Embodiments 1 and 2 is that the speed regulating motor 15 adopts a servo motor, and the rest are the same as Embodiments 1 and 2.

[0046] Lifting speed from zero and speed regulation in low-speed intervals of the device: the same as those in Embodiments 1 and 2.

[0047] Speed regulation in low-speed intervals and speed regulation in high-speed intervals: the same as Embodiments 1 and 2.

[0048] Speed regulation in the working speed range of the feed water pump (speed regulation in high-speed intervals): In Embodiments 1 and 2, the speed-regulating motor 15 is always in the state of feeding power to the utility power system 19 through the four-quadrant frequency converter 16. When reducing the four-quadrant frequency conversion When the output frequency of the device 16 reaches the lowest, the speed of the feed water pump 8 reaches the highest, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com