Multi-layer self-adhesive melt-blown cloth with sterilization and virus killing functions, production process and production line of multi-layer self-adhesive melt-blown cloth

A production process and virus-killing technology, applied in the direction of layered products, synthetic resin layered products, lamination, etc., can solve the problems that the sterilization and virus-killing function cannot be maintained for a long time, the process is complicated, and the users cannot be popularized, and the long-term maintenance is achieved. Stable action, easy popularization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further description will be made below in conjunction with drawings and embodiments.

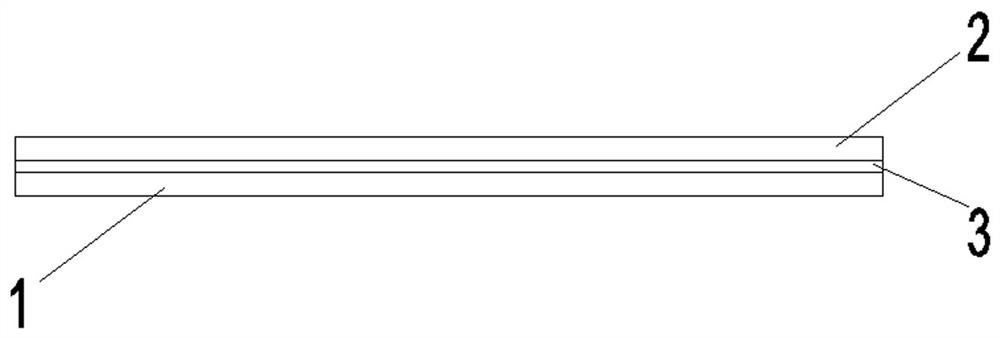

[0019] figure 1 Shown: a multi-layer self-adhesive melt-blown cloth with bactericidal and virus-killing functions, including a first mesh fiber cloth layer 1, a second mesh fiber cloth layer 2, a chemical sterilization and virus-killing component layer 3, the first net There is a chemical sterilizing and virus-killing component layer 3 between the mesh fiber cloth layer 1 and the second mesh fiber cloth layer 2, and the multilayer structure is superimposed and self-adhesive.

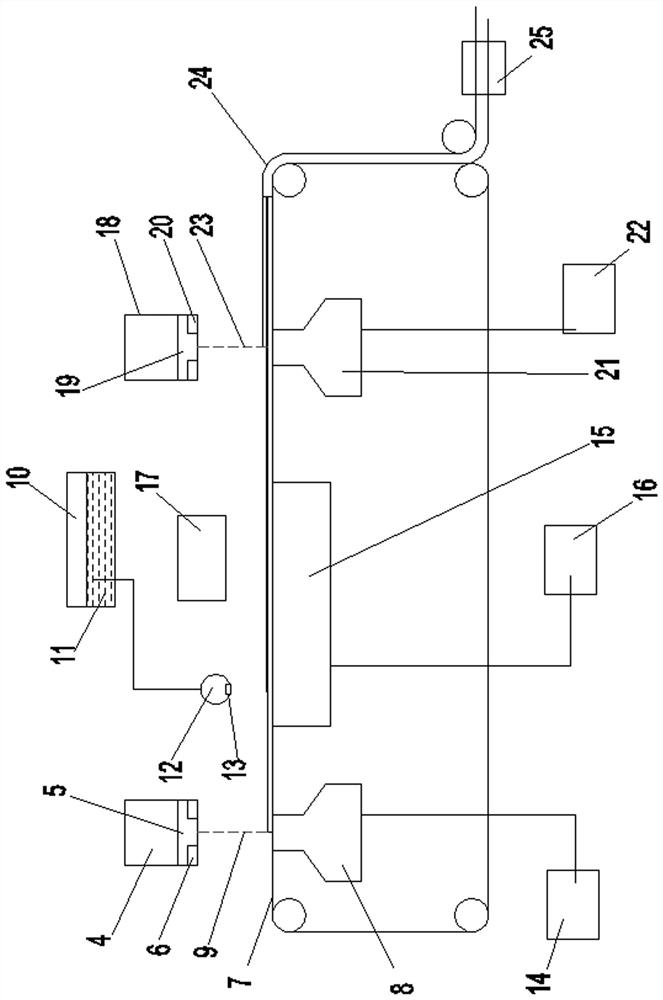

[0020] figure 2 Shown: a multi-layer self-adhesive melt-blown cloth production line with bactericidal and virus-killing functions, including the first die head 4, the first spinneret 5, the first drafting hot air port 6, the receiver breathable mesh curtain 7, First negative pressure suction box 8, liquid medicine atomization device 10, medicine pipe 12, medicine liquid atomization outlet 13, first negative p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com