Central intelligent water supply system of printing machine and process of central intelligent water supply system

A technology for intelligent water supply and printing machines, applied to printing machines, rotary printing machines, lithographic rotary printing machines, etc., can solve the problems of wasting energy, poor water level control accuracy, and insufficient intelligence, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

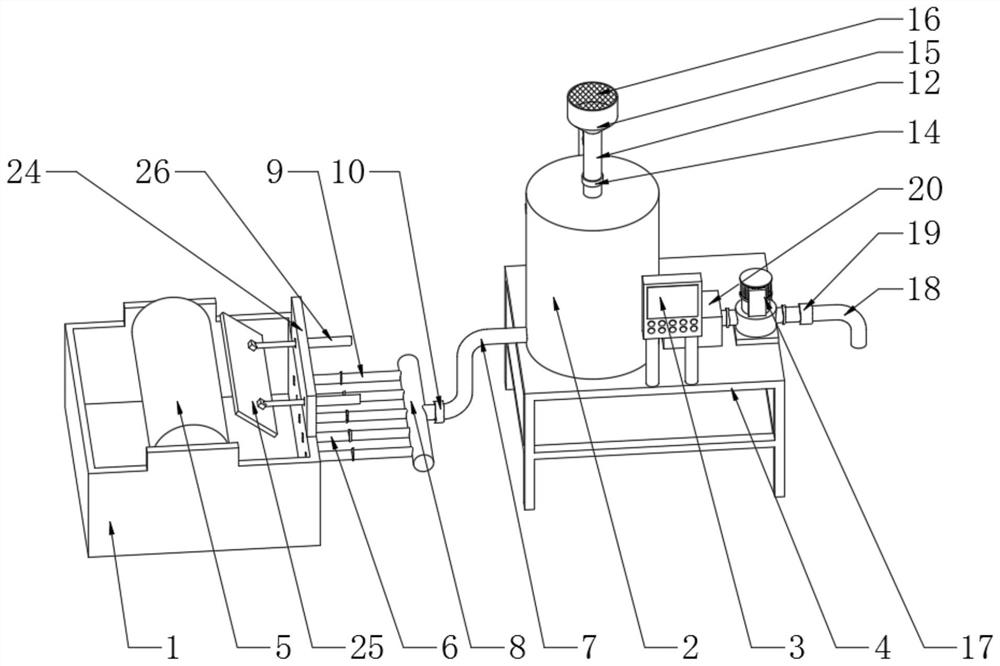

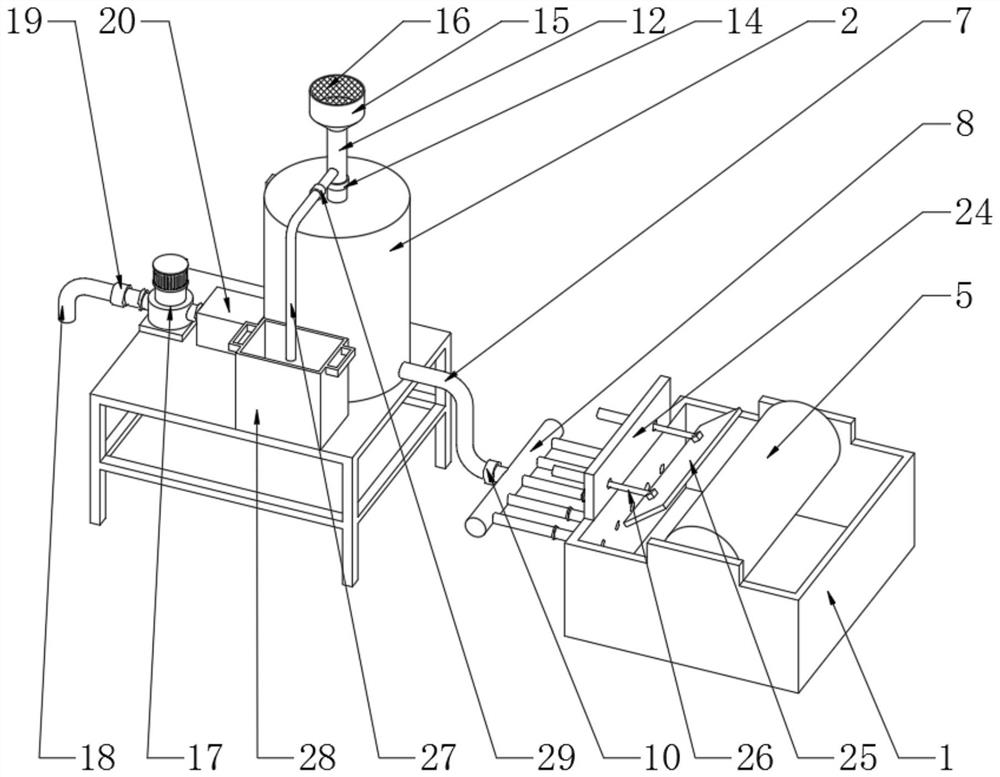

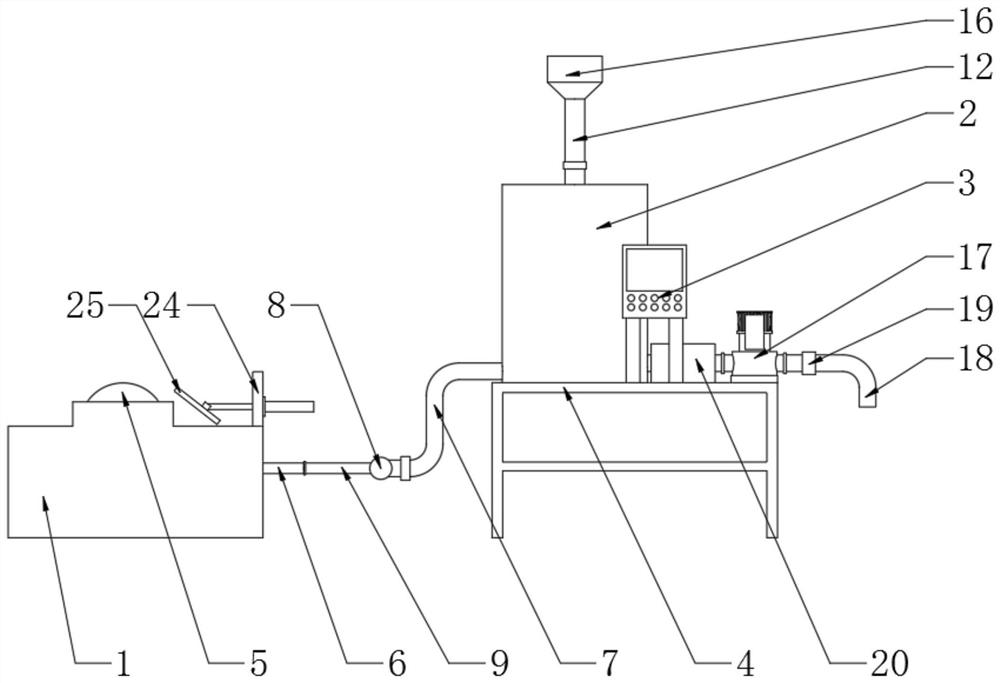

Method used

Image

Examples

Embodiment approach

[0046] The embodiment is specifically: during the rotation of the water roller 5, the water attached to the water roller 5 splashes on the inner surface of the baffle 25, and flows back into the water tank 1 along the inner surface of the baffle 25, reducing the amount of water in the water tank 1. The situation of splashing to the outside occurs, which improves the utilization rate of water resources. The PLC controller 3 controls the electric telescopic rod 26 to work, pushes the baffle 25 to move, and adjusts the distance between the baffle 25 and the water roller 5, so that the baffle 25 It can effectively intercept the water splashed by the water roller 5 when it rotates, which improves the interception effect. This embodiment specifically solves the problem in the prior art that the water is easily splashed out of the water tank when the water roller rotates, resulting in the waste of water resources.

[0047] The present invention also includes: a process for the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com