Explosion-proof raw material storage and conveying mechanism for chemical processing

A conveying mechanism and explosion-proof technology, which is used in the field of explosion-proof raw material storage and conveying mechanism for chemical processing, can solve the problems of lack of pressure relief and explosion-proof components, internal pressure changes, etc., and achieve the effect of stable and efficient use and increased stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

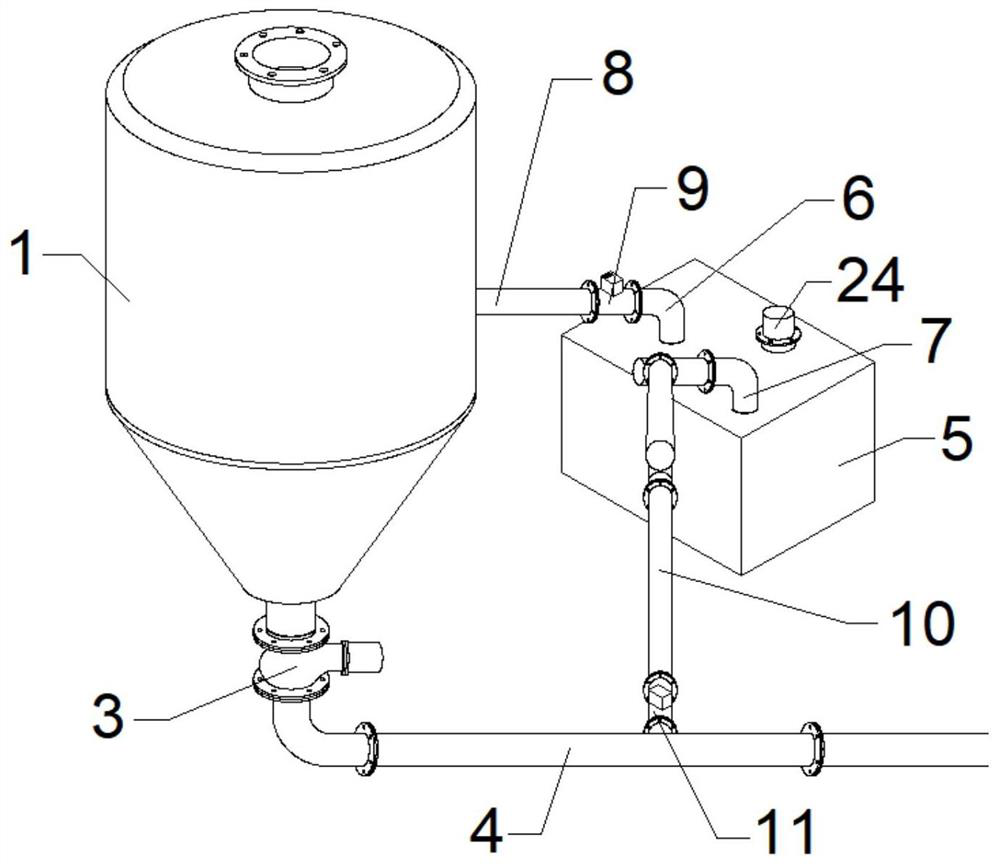

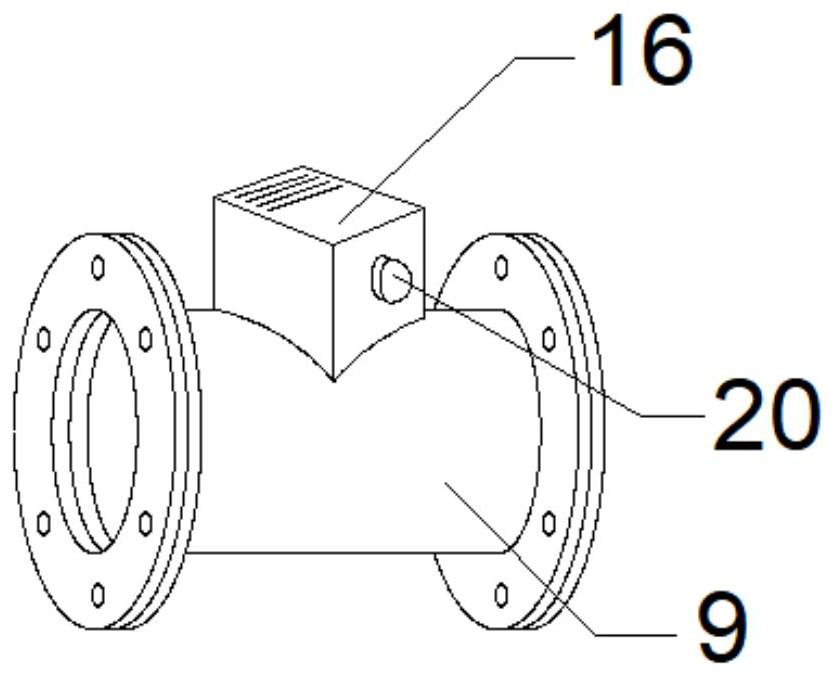

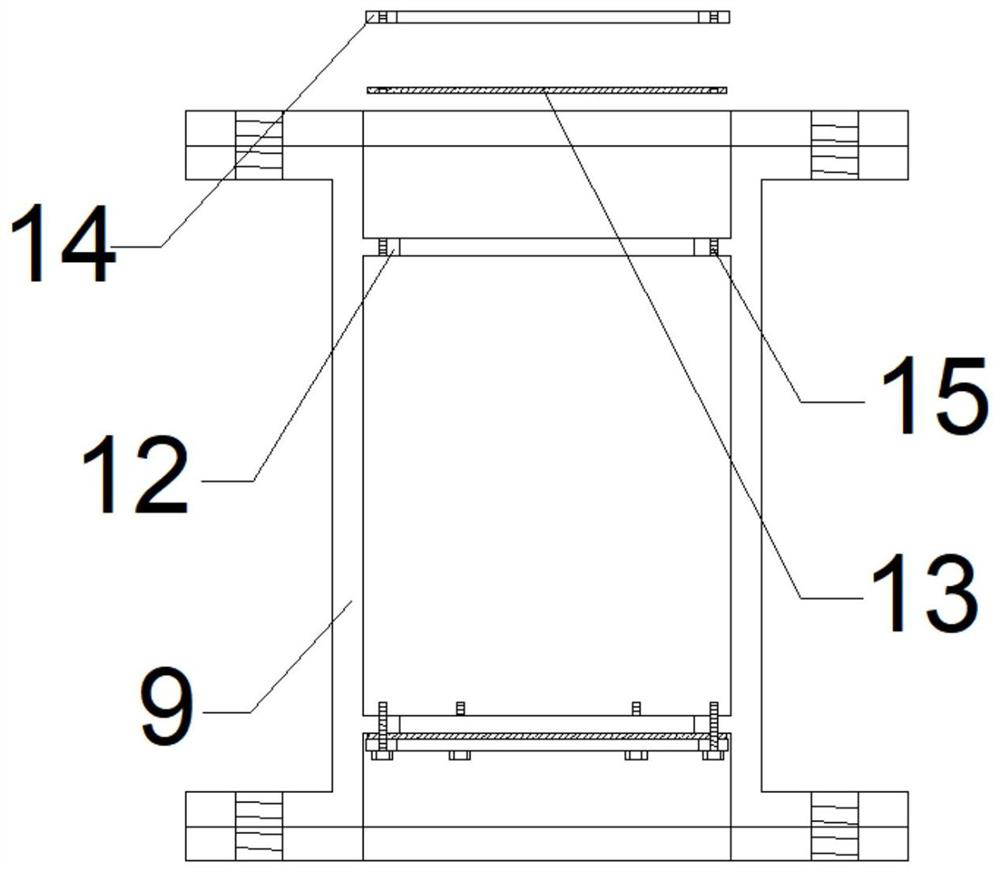

[0022] like Figure 1-4 As shown, an explosion-proof raw material storage and delivery mechanism for chemical processing includes a storage tank 1, a first pressure relief sleeve 9 and a second pressure relief sleeve 11, and also includes a monitoring host 16, a first pressure relief pipe 8 and The second pressure discharge pipe 10, the discharge end of the bottom of the storage tank 1 is equipped with an electric valve 3 through a flange, and the bottom of the electric valve 3 is equipped with a delivery pipe 4 through a flange, and one side of the storage tank 1 A recovery box 5 is provided, and the two ends of the top of the recovery box 5 are respectively provided with a first feed elbow 6 and a second feed elbow 7 integrated therewith, and one side of the storage tank 1 is connected by a flange. There is a first pressure relief pipe 8, the pressure relief end of the first pressure relief pipe 8 is installed with a first pressure relief sleeve 9 through a flange, and the o...

Embodiment 2

[0030] like Figure 1-4 As shown, an explosion-proof raw material storage and delivery mechanism for chemical processing includes a storage tank 1, a first pressure relief sleeve 9 and a second pressure relief sleeve 11, and also includes a monitoring host 16, a first pressure relief pipe 8 and The second pressure discharge pipe 10, the discharge end of the bottom of the storage tank 1 is equipped with an electric valve 3 through a flange, and the bottom of the electric valve 3 is equipped with a delivery pipe 4 through a flange, and one side of the storage tank 1 A recovery box 5 is provided, and the two ends of the top of the recovery box 5 are respectively provided with a first feed elbow 6 and a second feed elbow 7 integrated therewith, and one side of the storage tank 1 is connected by a flange. There is a first pressure relief pipe 8, the pressure relief end of the first pressure relief pipe 8 is installed with a first pressure relief sleeve 9 through a flange, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com