Automatic communication cable laying device

A technology for cable laying and automatic communication, applied in cable laying equipment, transportation and packaging, transportation of filamentous materials, etc. The effect of laying efficiency, reducing labor intensity and avoiding offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

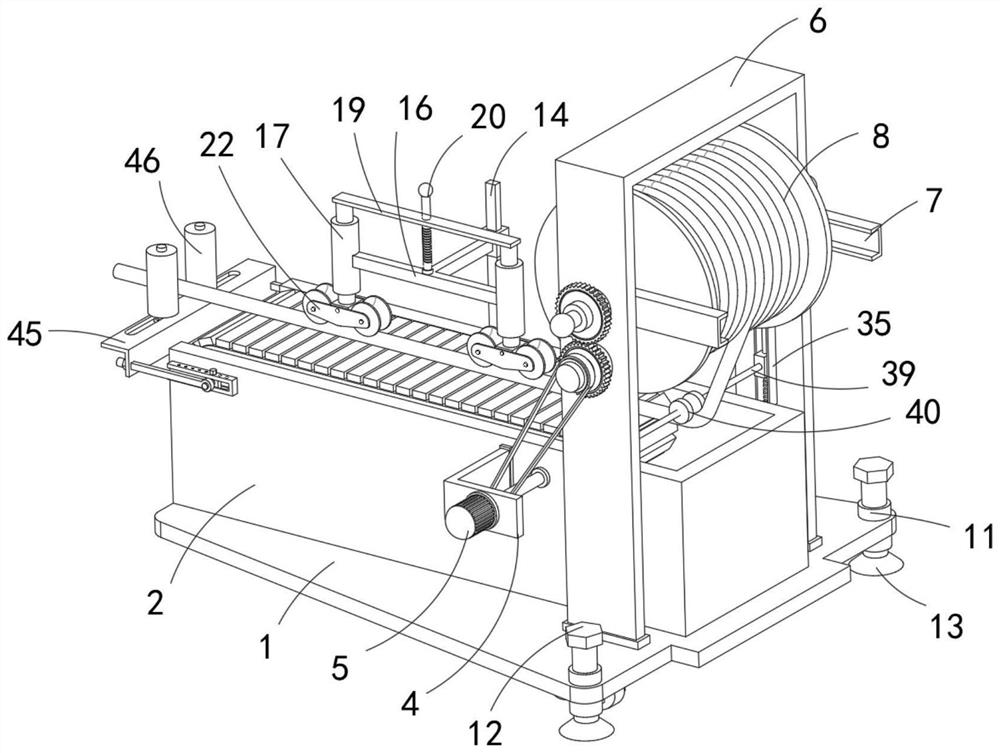

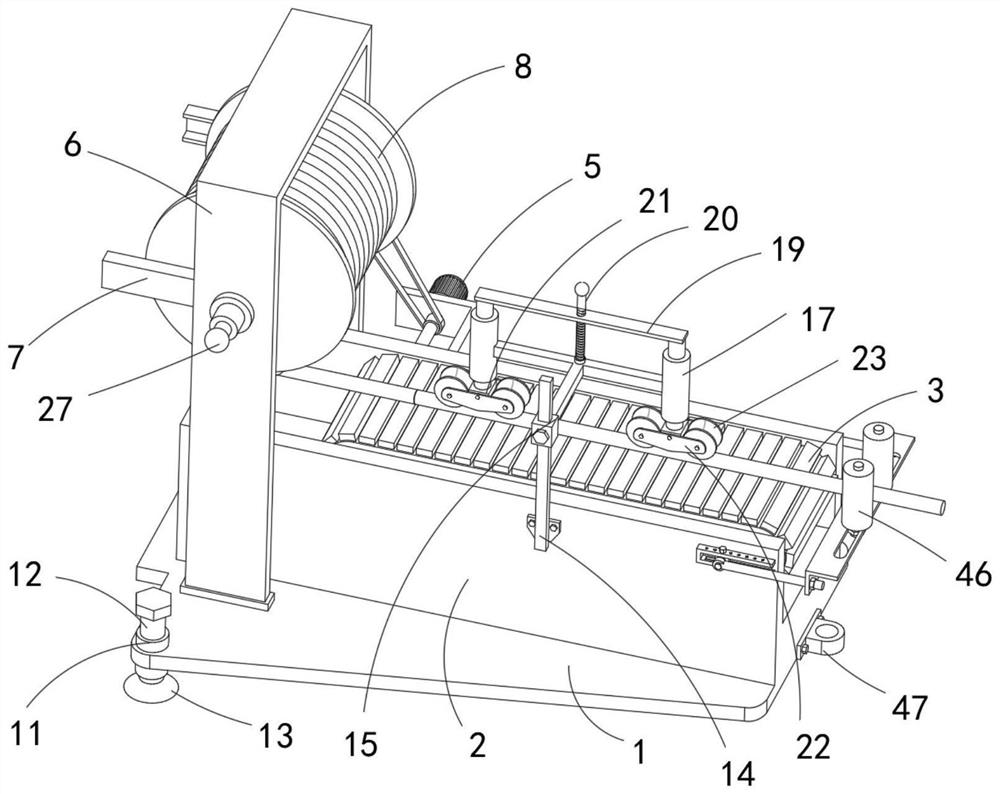

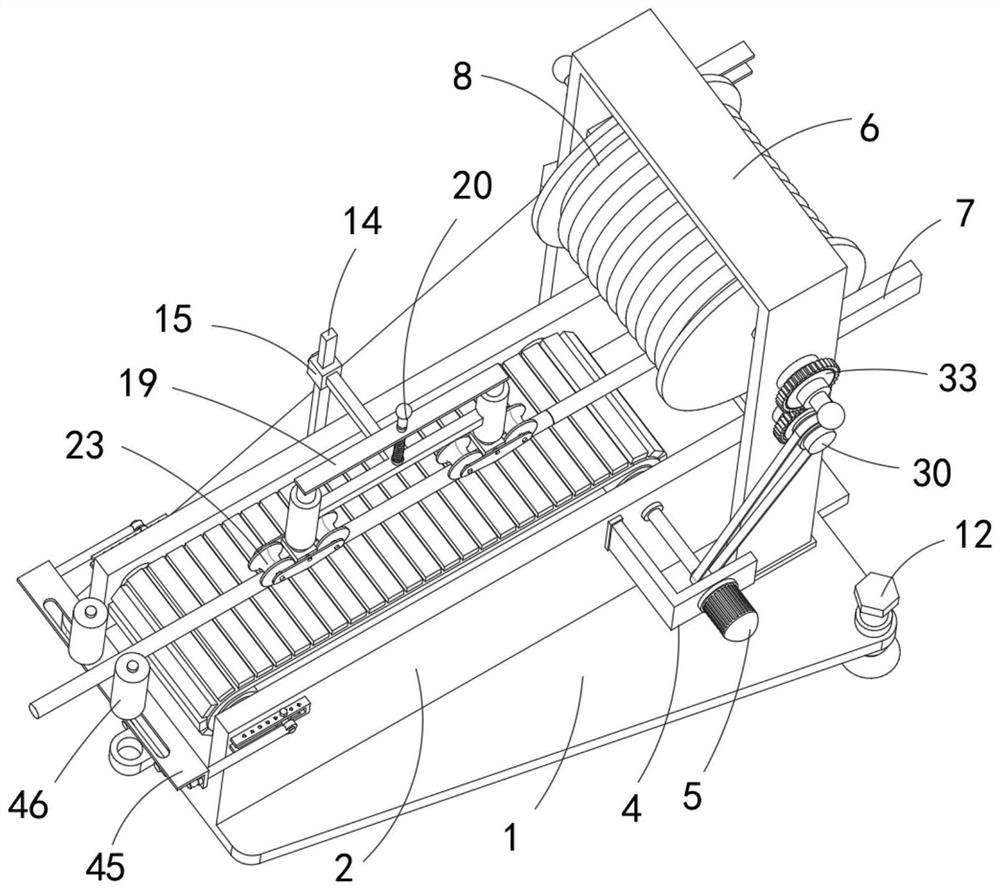

[0037] Refer Figure 1-8 An automatic communication cable laying device comprising the bottom plate 1 and the rectangular groove body 2, the rectangular groove body 2 is fixedly coupled to the upper end of the bottom plate 1, and the lower end of the bottom plate 1 is provided with a moving adjustment mechanism, and the moving adjustment mechanism includes a plurality of fixed connections on the bottom plate. 1 The lower U-shaped member 9, and the slot of the U-shaped member 9 is disposed downward, and the slot of the U-shaped member 9 is rotated and connected to the roller 10 in contact with the ground, and the upper end of the bottom plate 1 is fixedly connected with a plurality of vertical threads. The bobbin 11, and the threaded barrel 11 is threaded and attached to the vertical adjustment screw 12, and the lower end of the adjustment screw 12 extends to the lower side of the threaded tube 11 and fixed to the support 13 in contact with the ground, specifically L The bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com