Dry ice production device capable of reducing carbon dioxide loss and production method thereof

A carbon dioxide and production device technology, applied in chemical instruments and methods, liquefaction, inorganic chemistry, etc., can solve the problems of production operators' health hazards, inconformity with energy saving and consumption reduction, and high consumption, and achieve easy promotion, economic reliability, and operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

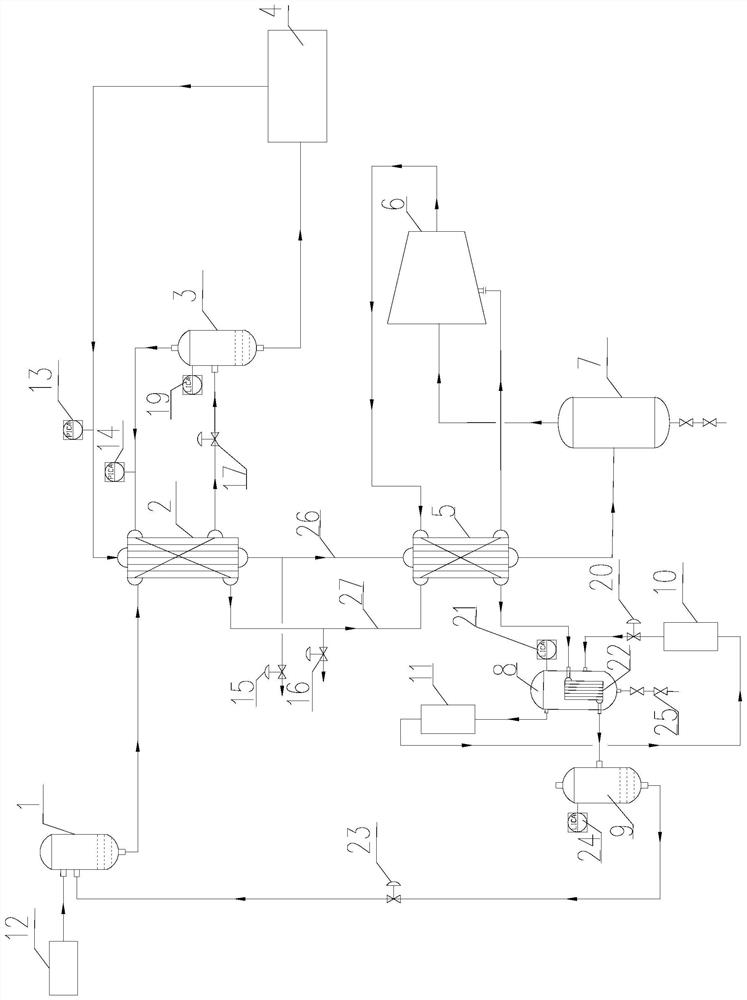

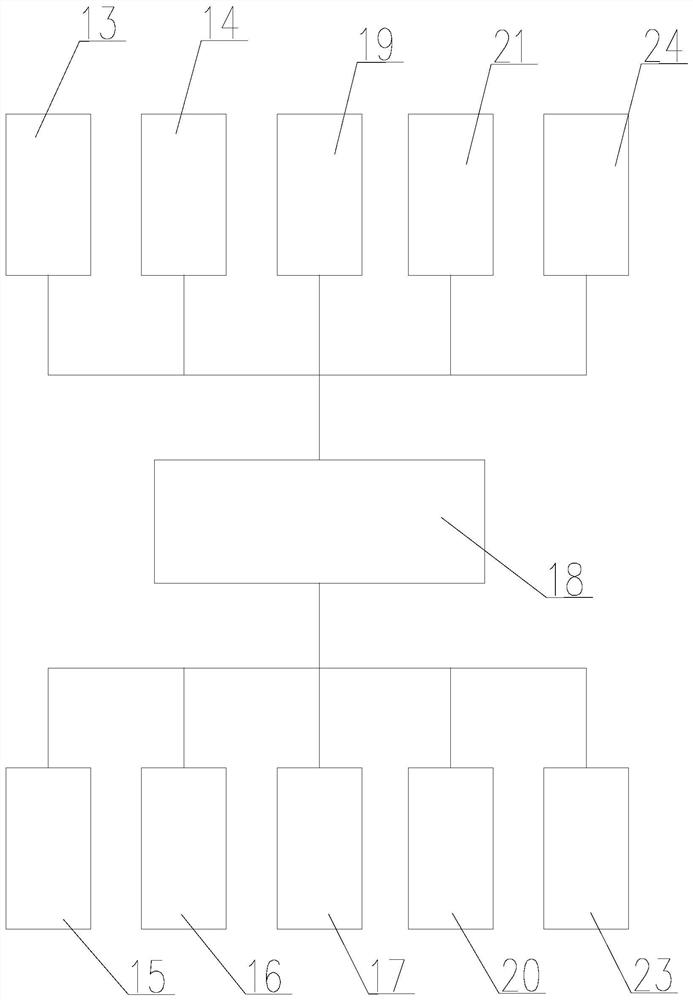

[0056]A dry ice production device that reduces carbon dioxide loss, comprising a liquid carbon dioxide production device 12, a liquid carbon dioxide storage tank 1 connected to the liquid carbon dioxide production device 12, and a dry ice granulator 4, the liquid carbon dioxide storage tank 1 is separated from the pre-cooling unit and The dry ice granulator 4 is connected, and the gas phase outlet of the pre-cooling separation unit and the dry ice granulator 4 is connected with the liquid carbon dioxide storage tank 1 through the gas phase recovery part; A liquefaction pre-cooling unit connected to the gas phase outlet, and a gas compression unit and a gas liquefaction unit connected to the liquefaction pre-cooling unit in turn; the pre-cooling separation unit includes a subcooler 2 connected to a liquid carbon dioxide storage tank 1, and the subcooler The hot end channel of 2 is connected with the first gas-liquid separator 3, and the liquid phase outlet of the first gas-liqui...

Embodiment 2

[0066] A dry ice production device that reduces carbon dioxide loss, comprising a liquid carbon dioxide production device 12, a liquid carbon dioxide storage tank 1 connected to the liquid carbon dioxide production device 12, and a dry ice granulator 4, the liquid carbon dioxide storage tank 1 is separated from the pre-cooling unit and The dry ice granulator 4 is connected, and the gas phase outlet of the pre-cooling separation unit and the dry ice granulator 4 is connected with the liquid carbon dioxide storage tank 1 through the gas phase recovery part; A liquefaction pre-cooling unit connected to the gas phase outlet, and a gas compression unit and a gas liquefaction unit connected to the liquefaction pre-cooling unit in turn; the pre-cooling separation unit includes a subcooler 2 connected to a liquid carbon dioxide storage tank 1, and the subcooler The hot end channel of 2 is connected with the first gas-liquid separator 3, and the liquid phase outlet of the first gas-liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com