Polyurethane coating liquid, paint surface protective film and preparation method of paint surface protective film

A polyurethane coating and coating liquid technology, applied in the field of coating liquid, can solve problems such as reducing infrared reflectivity, affecting product appearance, and cracking of metal layers, so as to reduce air-conditioning energy consumption, good infrared reflection durability, reduce absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A polyurethane coating solution provided in this embodiment is composed of the following raw materials in parts by weight: 50 kg of water-based polyol resin (Finanmark, RJ-006A), 8 kg of water-based curing agent (Finanmark, RJ-006B), nano silver Line dispersion (RAS, ECOS HC) 100kg, 16-mercaptohexadecan-1-ol (Bailingwei Technology Co., Ltd.) 2kg and ethanol 50kg.

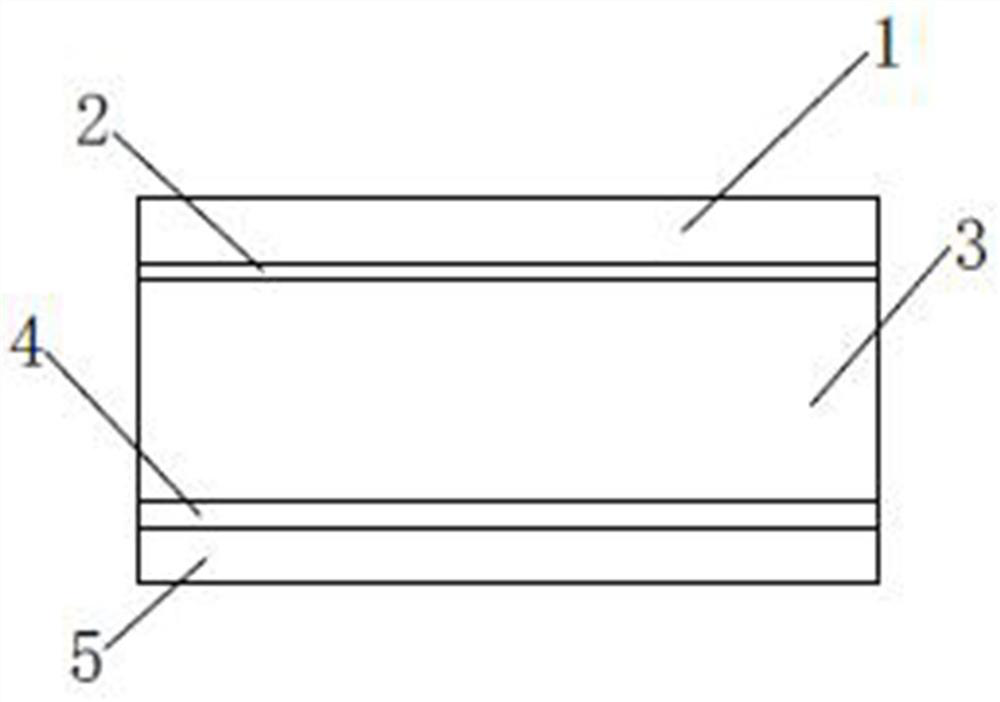

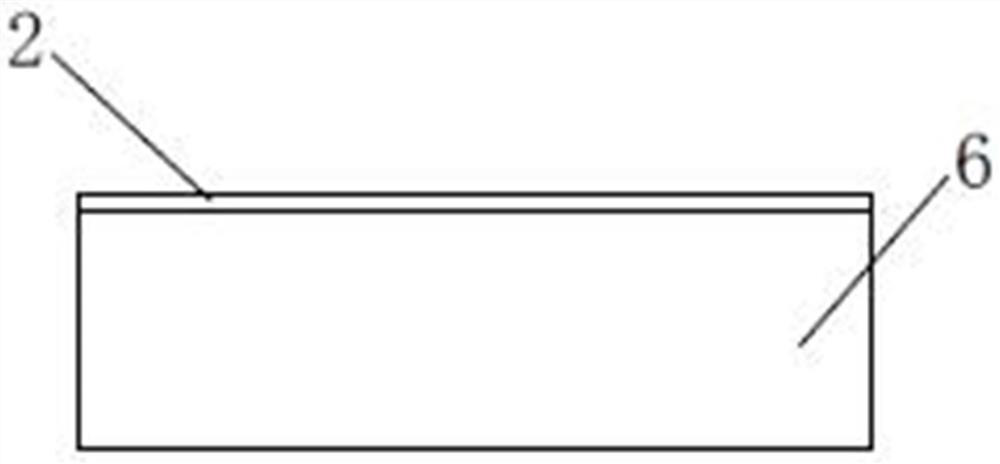

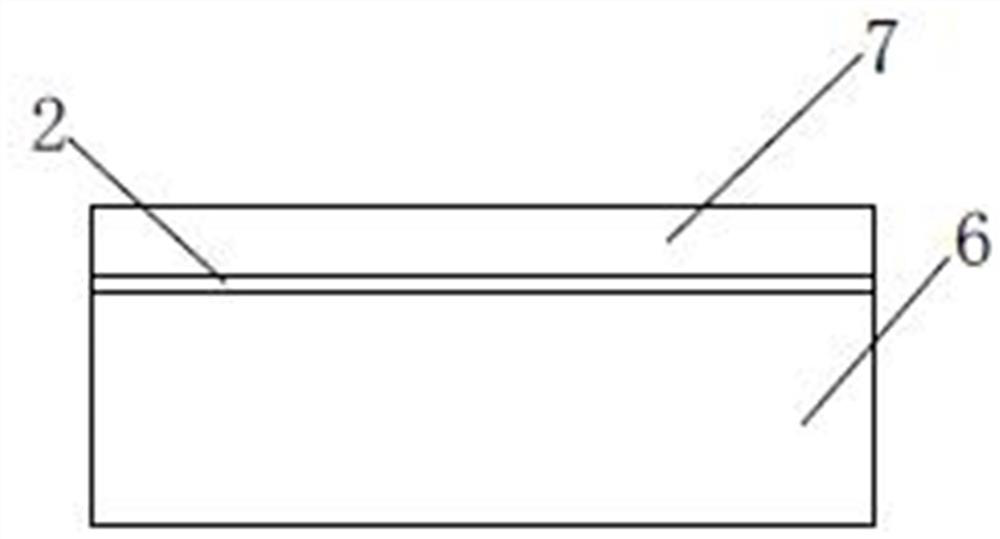

[0039] A kind of paint protection film that the present embodiment provides, comprises the transparent PET protective film layer with silica gel that is laminated successively with a thickness of 44 μm, the above-mentioned polyurethane coating with a thickness of 10 μm, and a thermoplastic polyurethane (TPU) film layer (TPU) with a thickness of 150 μm ( Argotec, 49510), acrylic pressure-sensitive adhesive layer (Ashland, 9510H) with a thickness of 20 μm and a PET release film layer with a thickness of 36 μm.

[0040] The present embodiment provides a kind of preparation method of paint protection film, it com...

Embodiment 2

[0045] A polyurethane coating solution provided in this embodiment is composed of the following raw materials in parts by weight: 50 kg of water-based polyol resin (Finanmark, RJ-006A), 10 kg of water-based curing agent (Finanmark, RJ-006B), nano silver Line dispersion (RAS, ECOS HC) 120kg, 16-mercaptohexadecan-1-ol (Bailingwei Technology Co., Ltd.) 2.4kg and ethanol 60kg.

[0046] A kind of paint protection film that the present embodiment provides, comprises the transparent PET protective film layer with silica gel that is laminated successively with a thickness of 44 μm, the above-mentioned polyurethane coating with a thickness of 10 μm, and a thermoplastic polyurethane (TPU) film layer (TPU) with a thickness of 150 μm ( Argotec, 49510), acrylic pressure-sensitive adhesive layer (Ashland, 9510H) with a thickness of 25 μm and a PET release film layer with a thickness of 36 μm.

[0047] The present embodiment provides a kind of preparation method of paint protection film, it ...

Embodiment 3

[0052] A polyurethane coating solution provided in this embodiment is composed of the following raw materials in parts by weight: 50 kg of water-based polyol resin (Finanmark, RJ-006A), 12 kg of water-based curing agent (Finanmark, RJ-006B), nano silver Line dispersion (RAS, ECOS HC) 150kg, 16-mercaptohexadecan-1-ol (Bailingwei Technology Co., Ltd.) 3kg and ethanol 70kg.

[0053] A kind of paint protective film provided by the present embodiment comprises a layer of transparent PET protective film with silica gel with a thickness of 57 μm, the above-mentioned polyurethane coating with a thickness of 10 μm, and a thermoplastic polyurethane (TPU) film layer with a thickness of 150 μm ( Argotec, 49510), acrylic pressure-sensitive adhesive layer (Ashland, 9510H) with a thickness of 20 μm and a PET release film layer with a thickness of 50 μm.

[0054] The present embodiment provides a kind of preparation method of paint protection film, it comprises the following concrete steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com