Rapid rectification system for waste oil regeneration

A rectification system and waste oil regeneration technology, which is applied in the petroleum industry, hydrocarbon oil treatment, and multi-stage serial refining process treatment. Damage, unable to install the agitator and other problems, to achieve the effect of low production cost, high power consumption and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

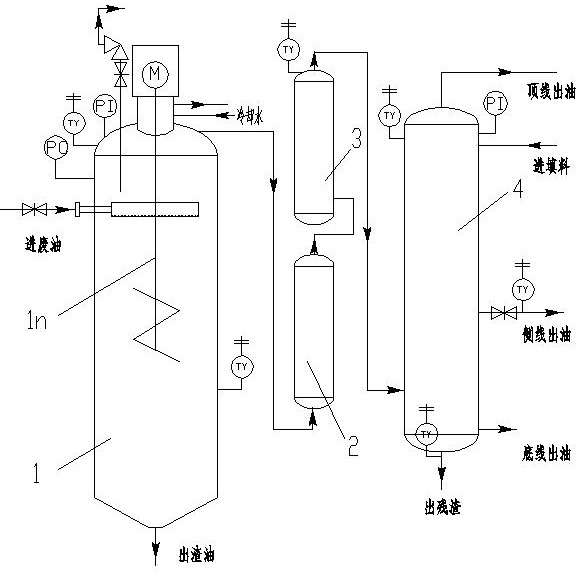

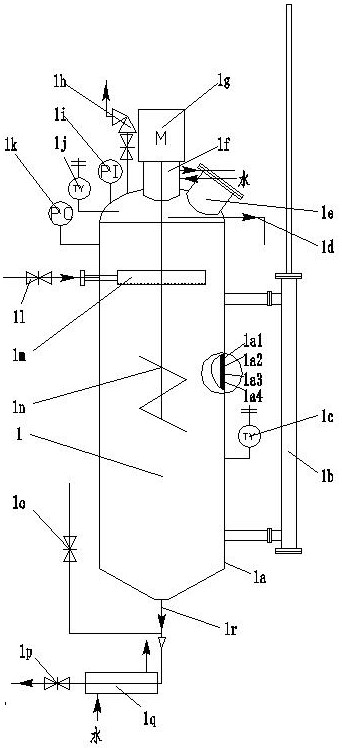

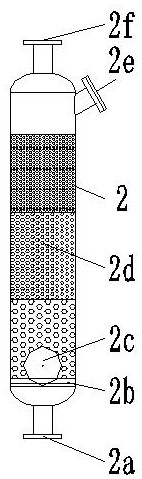

[0028] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , a waste oil regeneration fast rectification system, the system uses pipes, pipe fittings, and valves to connect the reactor tank 1, adsorption tower 2, catalytic tower 3, and fractionation tower 4 in series; the waste oil enters from the oil inlet pipe valve 1l Reactor tank 1, then through adsorption tower 2, catalytic tower 3, fractionation tower 4, and finally the regenerated light oil produced by rectification is discharged from the top line oil outlet 4p of catalytic tower 3, and the light regenerated base oil produced by rectification Discharge from catalytic tower 3 side line oil outlet 4r, the heavy regeneration base oil that rectification produces is discharged from the bottom oil outlet 4a of catalytic tower 3; Described reactor 1 adopts electromagnetic heating, and the power of electromagnetic heating is 60-180Kw; The reactor tank body 1a ...

Embodiment 2

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , a waste oil regeneration fast rectification system, the system uses pipes, pipe fittings, and valves to connect the reactor tank 1, adsorption tower 2, catalytic tower 3, and fractionation tower 4 in series; the waste oil enters from the oil inlet pipe valve 1l Reactor tank 1, then through adsorption tower 2, catalytic tower 3, fractionation tower 4, and finally the regenerated light oil produced by rectification is discharged from the top line oil outlet 4p of catalytic tower 3, and the light regenerated base oil produced by rectification Discharge from catalytic tower 3 side line oil outlet 4r, the heavy regeneration base oil that rectification produces is discharged from the bottom oil outlet 4a of catalytic tower 3; Described reactor 1 adopts electromagnetic heating, and the power of electromagnetic heating is 60-180Kw; The reactor tank body 1a ...

Embodiment 3

[0032] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , a waste oil regeneration fast rectification system, the system uses pipes, pipe fittings, and valves to connect the reactor tank 1, adsorption tower 2, catalytic tower 3, and fractionation tower 4 in series; the waste oil enters from the oil inlet pipe valve 1l Reactor tank 1, then through adsorption tower 2, catalytic tower 3, fractionation tower 4, and finally the regenerated light oil produced by rectification is discharged from the top line oil outlet 4p of catalytic tower 3, and the light regenerated base oil produced by rectification Discharge from catalytic tower 3 side line oil outlet 4r, the heavy regeneration base oil that rectification produces is discharged from the bottom oil outlet 4a of catalytic tower 3; Described reactor 1 adopts electromagnetic heating, and the power of electromagnetic heating is 60-180Kw; The reactor tank body 1a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com