Method for strengthening surface of 2024 aluminum alloy

A surface strengthening, aluminum alloy technology, applied in the field of shot peening, can solve the problem of difficult to meet the performance requirements of 2024 aluminum alloy parts, and achieve the effect of improving shot peening efficiency, high shot peening coverage and less material damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

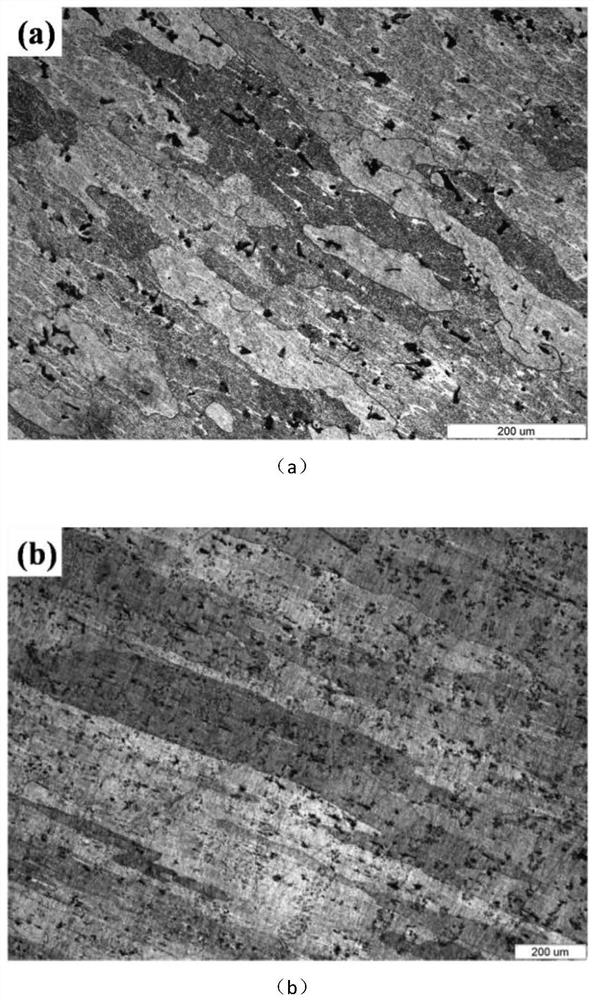

Embodiment 1

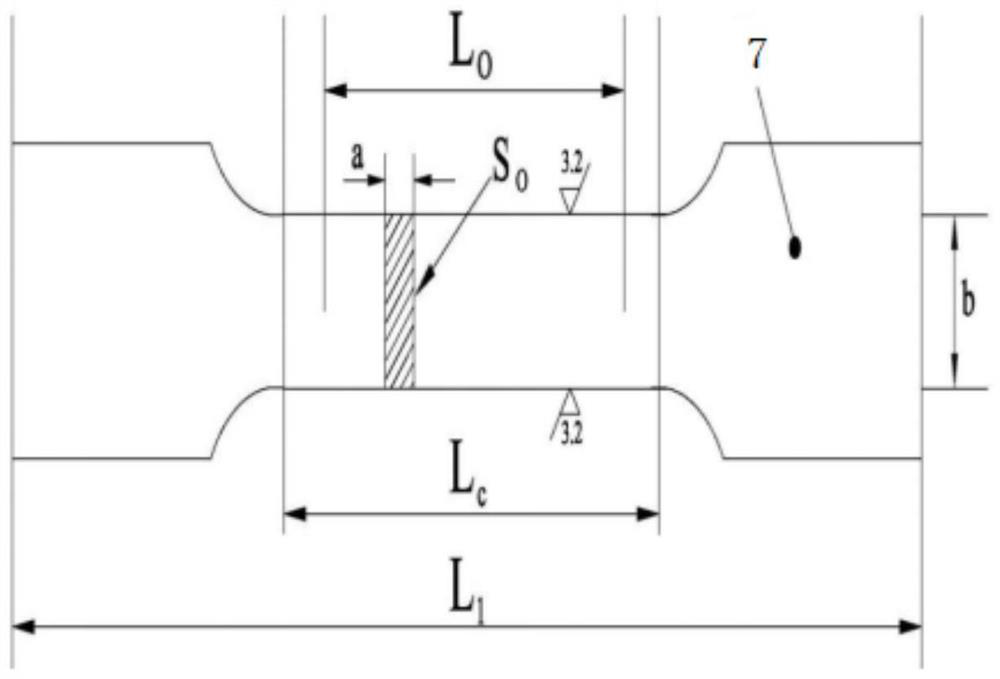

[0033] (1) The 2024 aluminum alloy thick plate was prepared into a tensile sample along the rolling direction. Before the test, the sample was ground and polished with silicon carbide sandpaper, and cleaned with alcohol.

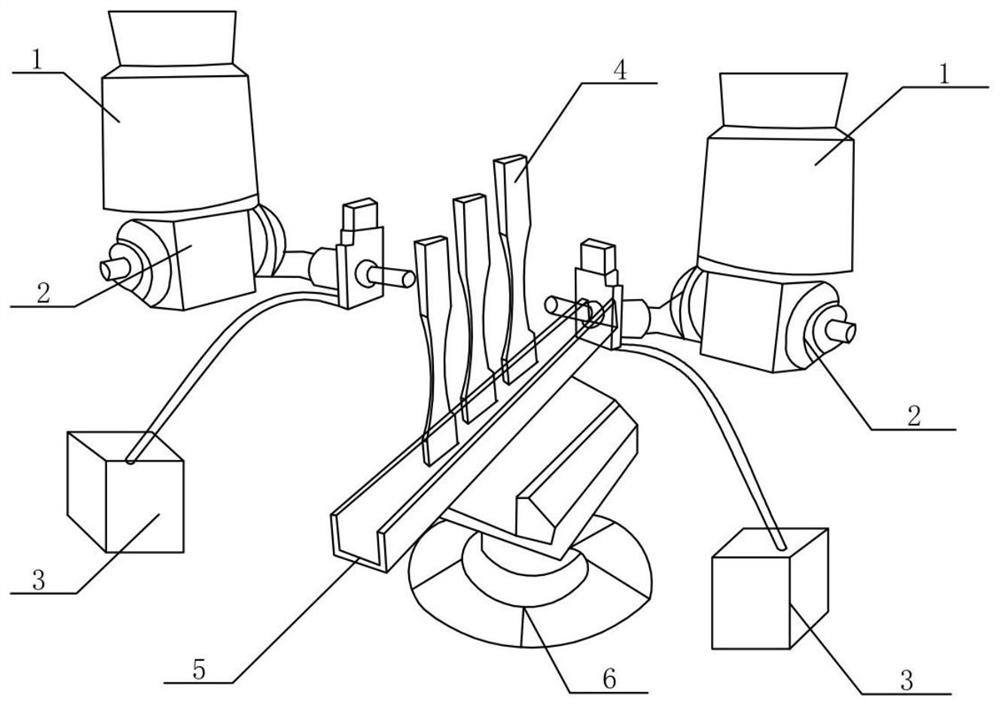

[0034] (2) Put the prepared tensile sample on the fixture of the shot peening device for shot peening. Shot peening parameters are as follows: Shot peening angle: 90°, double-sided single nozzle spraying; flow rate: 10kg / min; shot peening distance: 500mm; moving speed: 3.0m / min; injection pressure 0.4MPa; projectiles are carbon steel projectiles , the particle size is 3.18mm, and the shot peening time is 30min.

Embodiment 2

[0036] (1) The 2024 aluminum alloy thick plate was prepared into a tensile sample along the rolling direction. Before the test, the sample was ground and polished with silicon carbide sandpaper, and cleaned with alcohol.

[0037] (2) Put the prepared tensile sample on the fixture of the shot peening device for shot peening. Shot peening parameters are as follows: Shot peening angle: 90°, double-sided single nozzle spraying; flow rate: 10kg / min; shot peening distance: 500mm; moving speed: 3.0m / min; injection pressure 0.5MPa; projectiles are carbon steel projectiles , the particle size is 3.18mm, and the shot peening time is 30min.

Embodiment 3

[0039] (1) The 2024 aluminum alloy thick plate was prepared into a tensile sample along the rolling direction. Before the test, the sample was ground and polished with silicon carbide sandpaper, and cleaned with alcohol.

[0040] (2) Put the prepared tensile sample on the fixture of the shot peening device for shot peening. Shot peening parameters are as follows: Shot peening angle: 90°, double-sided single nozzle spraying; flow rate: 10kg / min; shot peening distance: 500mm; moving speed: 3.0m / min; injection pressure 0.6MPa; projectiles are carbon steel projectiles , the particle size is 3.18mm, and the shot peening time is 30min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com