Continuous disperse dye pad-dyeing method for polyamide braids and fabrics

A disperse dye and disperse dyeing technology, applied in the field of textile printing and dyeing, to achieve the effect of strong covering, good color fastness and small color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

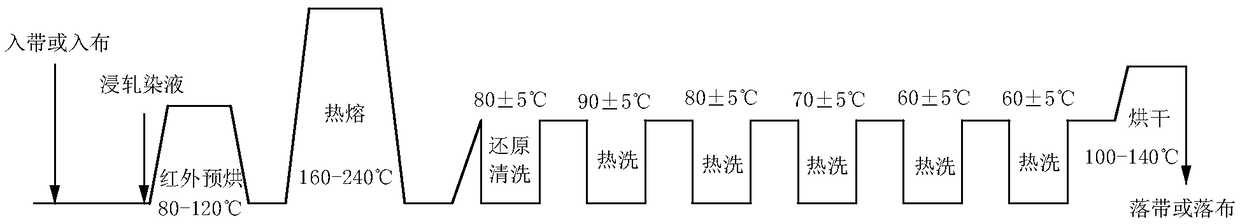

[0036] The present embodiment provides a method for continuous pad dyeing of nylon webbing with disperse dyes, comprising the following steps:

[0037] 1. Pre-treatment: use 43-800 brocade ribbons made of nylon 6, and process the brocade ribbons according to the steps of tape drop-seaming-refining treatment-drying. Among them, the tape drop is to arrange the brocade ribbons into The state suitable for refining treatment and dyeing is equivalent to the opening process of cloth, so that the brocade ribbon to be refined and dyed can be kept flat without twisting. The seam head is made of aramid fiber, so that the joints are kept as straight as possible without bulges, and then the brocade ribbon is treated with refining liquid at a temperature of 86±1°C. During the refining process, the speed is set at 8m / min. After the refining process is completed, it is dried in a hot air oven at 130°C.

[0038]2. Dyeing treatment: Put the two brocade ribbons that have been refined side by si...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is mainly that: 20-150 brocade ribbons made of nylon 6 are used, and the blank tapes of the brocade ribbons are directly dyed after the tape-drop-sewing treatment, and the two brocade ribbons are juxtaposed at the same time. Into the strip, the speed of the control equipment is 9m / min, and the elongation ratio is 100%. At a temperature of 42±2°C, the pretreated silk strip is padded with disperse dye solution, and the padding pressure is adjusted to 2.2bar, and the padding tension is 2.5 bar, after two dipping and two rolling, the brocade ribbon is treated according to the steps of infrared pre-baking-hot melt baking-reduction cleaning-washing-drying. Among them, the temperature of infrared pre-baking is 100°C, the temperature of hot-melt baking is 165°C, and then the brocade ribbon is cleaned with reducing lotion, and the temperature of the reducing lotion is kept within the range of 78±2°C. Wash the brocade ribbon...

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is mainly that: the 11-600 brocade ribbon made of nylon 6 is used, and the blank tape of the brocade ribbon is directly dyed after the tape-drop-sewing treatment, and the two brocade ribbons are juxtaposed at the same time. Into the belt, the speed of the control equipment is 8m / min, the elongation ratio is 100%, and the pretreated brocade ribbon is padded with the disperse dye solution at a temperature of 62±2°C, and the padding pressure is adjusted to 3bar, and the padding tension is 2bar. After two dips and two rollings, the brocade ribbons are treated according to the steps of infrared pre-baking-hot melt baking-reduction cleaning-washing-drying. Among them, the temperature of infrared pre-baking is 120°C, the temperature of hot-melt baking is 200°C, and then the brocade ribbon is cleaned with reducing lotion, and the temperature of the reducing lotion is kept within the range of 83±2°C. Wash the brocade ribbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com