Nano ink for realizing multicolor anode of aluminum alloy

An aluminum alloy and anode technology, which is applied in ink, anodic oxidation, electrolytic coating, etc., can solve the problems of long process flow, complicated process, and lack of mass production, and achieve the effect of clean spraying environment, short process flow and accurate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] A nano-ink for realizing aluminum alloy multi-color anode, characterized in that it is made of raw materials according to the following proportions, including: 70-80% of modified acrylic resin, 16-24% of ultra-fine nano-pigment, non-silicon defoamer 1 -2%, leveling agent 1-2% and special curing agent 1-2%.

[0036] A preparation method of nano-ink for realizing aluminum alloy multi-color anode, comprising the steps of:

[0037] Step S1: Grinding and dispersing the modified acrylic resin plus ultra-fine nano-pigments through a swing grinding device at high speed;

[0038] Step S2: Add non-silicon defoamer and leveling agent, vacuum defoaming;

[0039] Step S3: After degassing, use a vacuum filter to vacuum filter the mixed material;

[0040] Step S4: curing by adding a special curing agent to realize the preparation of the ink.

[0041] A coating process for realizing the nano-ink of aluminum alloy multi-color anode, comprising the following steps:

[0042] Step 1: u...

Embodiment approach

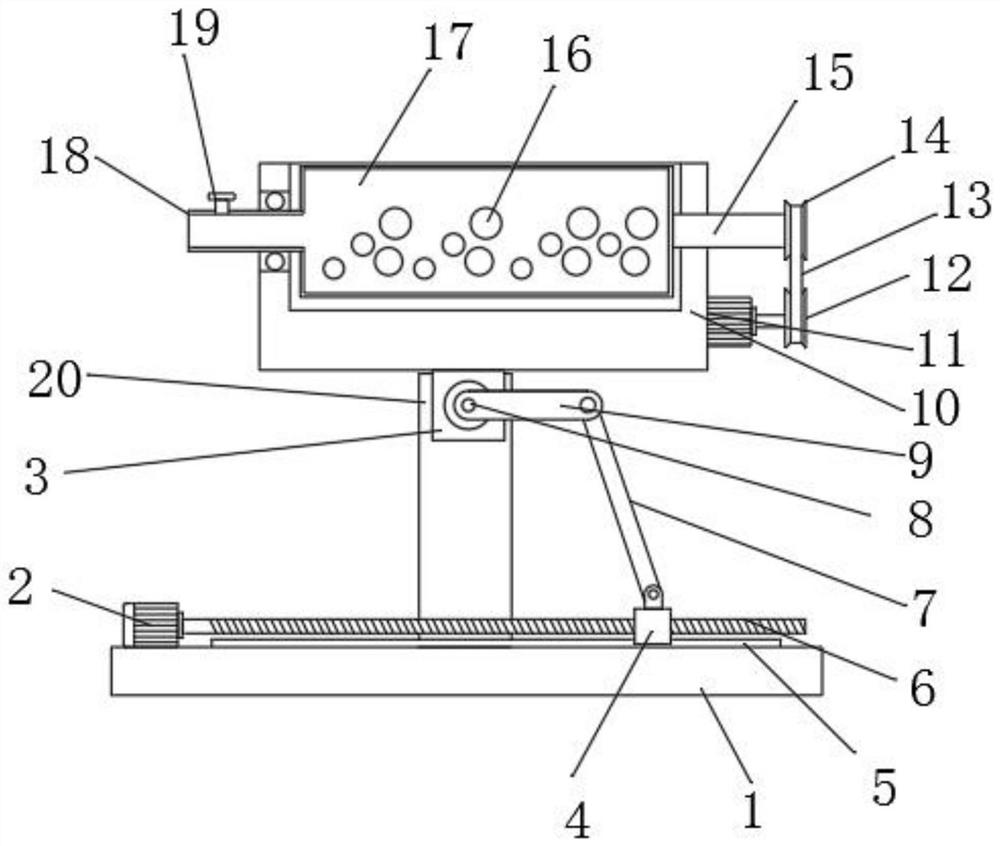

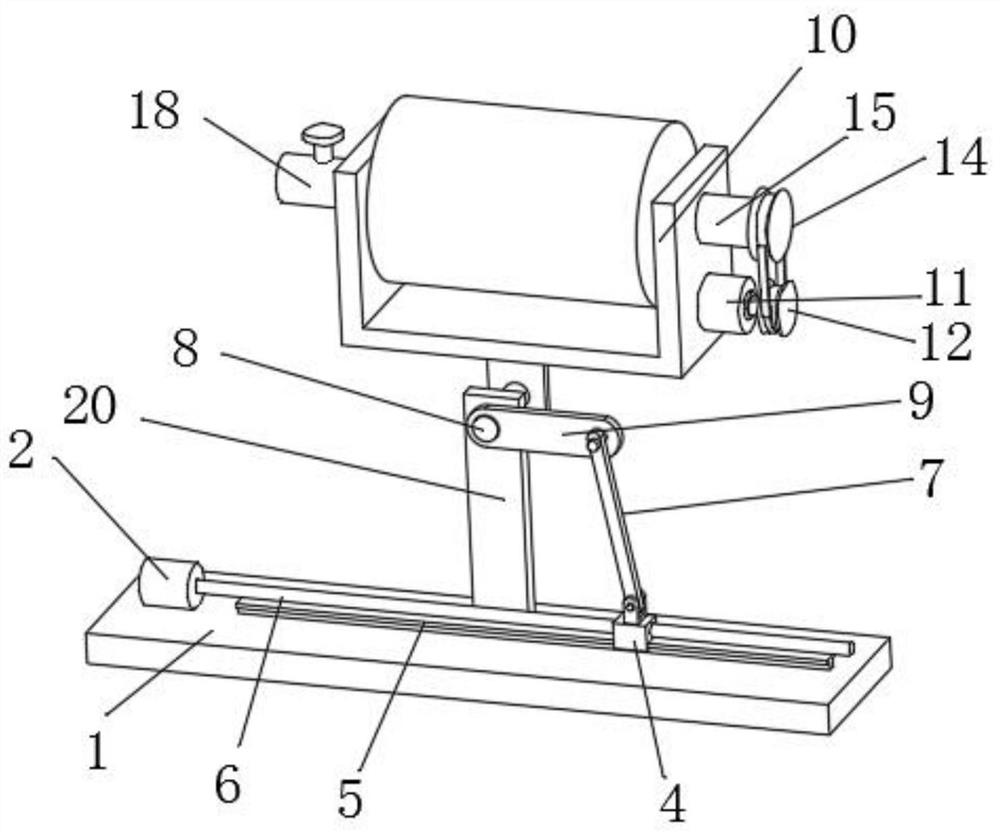

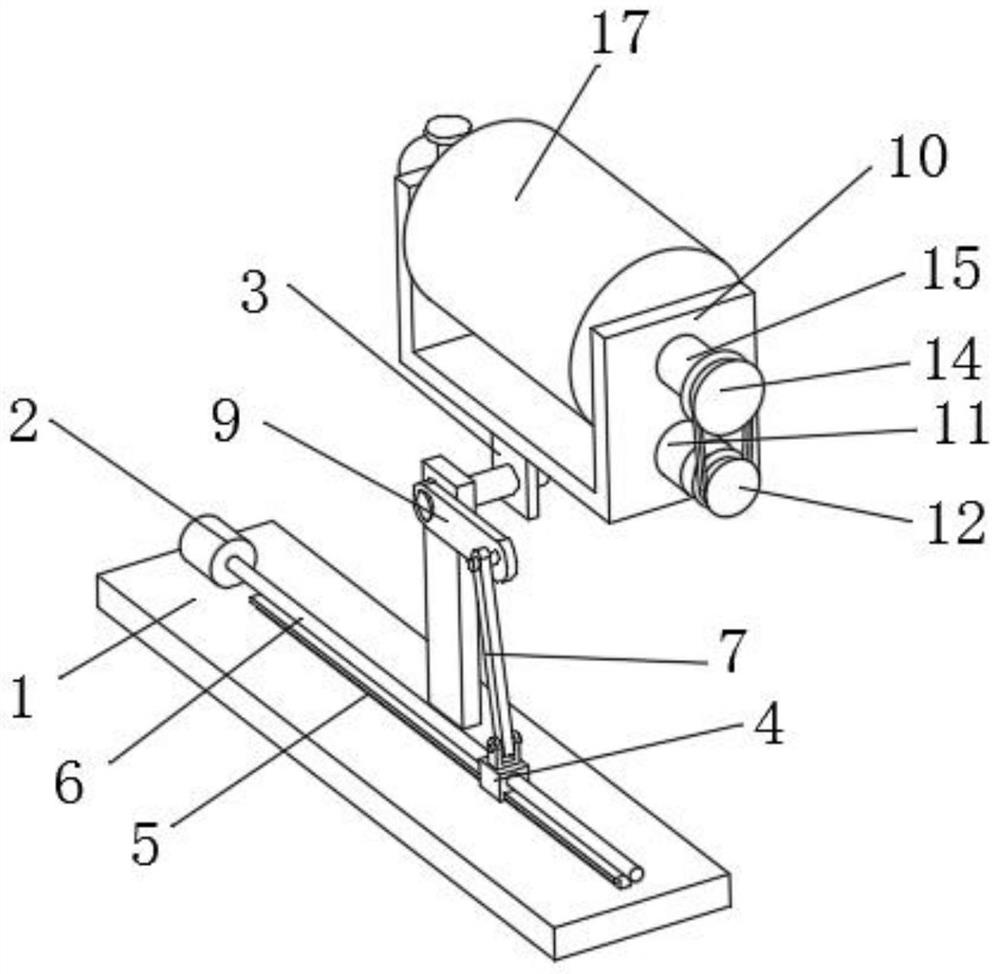

[0047] As an embodiment of the present invention, the swing grinding device includes a base 1, a conveying motor 2, a support plate 3, a slider 4, a slide rail 5, a screw rod 6, a pull rod 7, a swing shaft 8, a swing rod 9, and a rolling frame 10 , rolling motor 11, driving pulley 12, transmission belt 13, driven pulley 14, solid shaft 15, grinding ball 16, grinding cylinder 17, hollow shaft 18, valve 19 and fixed frame 20, the top side of base 1 is fixed with slide Rail 5, slide rail 5 is buckled with slider 4, conveying motor 2 is installed on base 1, screw rod 6 is installed on the rotating shaft of conveying motor 2, screw hole is opened inside slider 4, and screw rod 6 is penetrated In the screw hole, the fixed frame 20 is fixed on the top side of the base 1, the top of the fixed frame 20 is fitted with a swing shaft 8 through a bearing, one end of the swing shaft 8 is fixed with a swing rod 9, and the bottom end of the pull rod 7 is mounted through a hinge. On the slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com