Fabric with relatively high air permeability and production process

A technology of production technology and air permeability, which is applied in the field of cloth with strong air permeability and production technology, which can solve the problems of increasing hot feeling, hindering body heat loss and sweat evaporation, so as to ensure air permeability, facilitate timely evaporation, and good Shaped effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

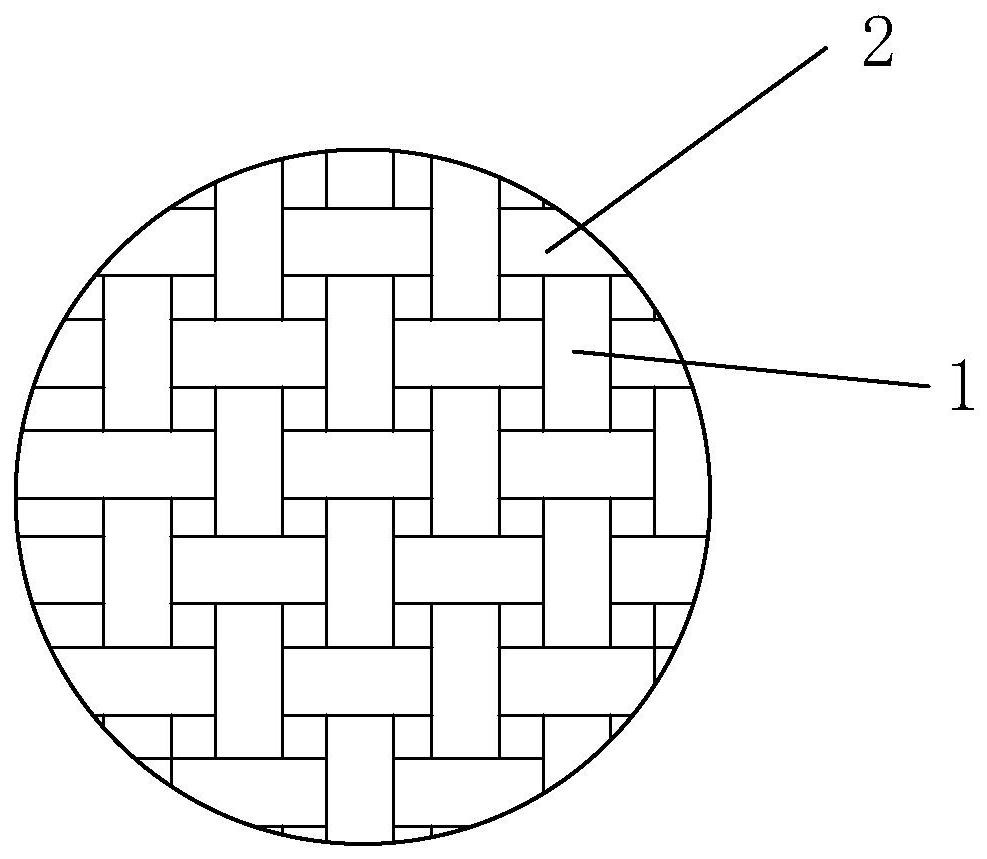

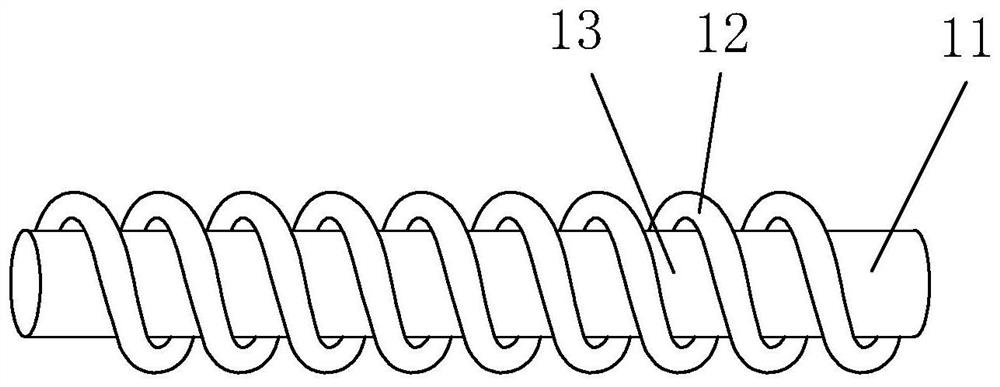

[0025] A fabric with strong air permeability, such as figure 1 As shown, it is woven by warp yarn 1 and weft yarn 2 through warp and weft insertion, wherein warp yarn 1 and weft yarn 2 are core-spun yarns, such as figure 2 As shown, the warp yarn 1 and the weft yarn 2 are both composed of the inner core yarn 11 and the air-permeable yarn 12, and the air-permeable yarn 12 has a spiral structure formed on the surface of the inner core yarn 11, and the gap between the spiral structures is the air guide channel 3; The existence of the air guide channel 13 increases the air permeability of the cloth, so that the cloth has better air permeability.

[0026] For the inner core yarn 11, spandex elastic yarn with excellent wear resistance and structural strength can be used. The spandex elastic yarn has certain elasticity, so that the cloth h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com