Bridge pier isolation type composite elastic ship collision prevention bent frame structure system and construction method thereof

A composite material and construction method technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as poor corrosion resistance, difficult repair, short life cycle, etc., and achieve simple, convenient and fast construction, good anti-collision effect, and improved The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

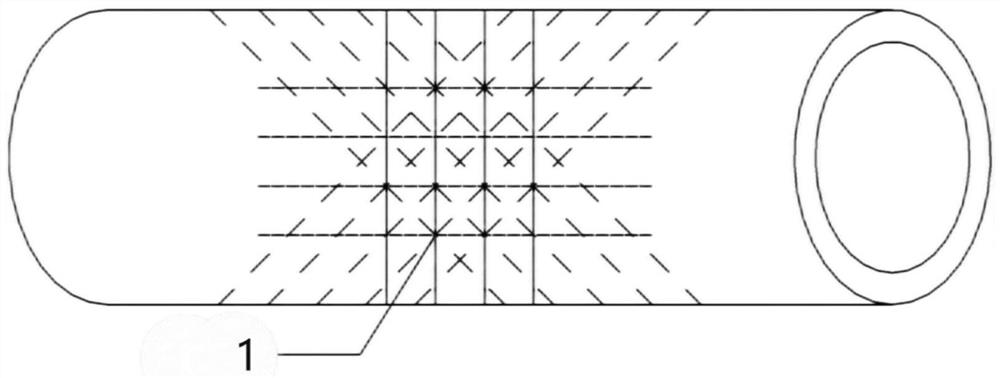

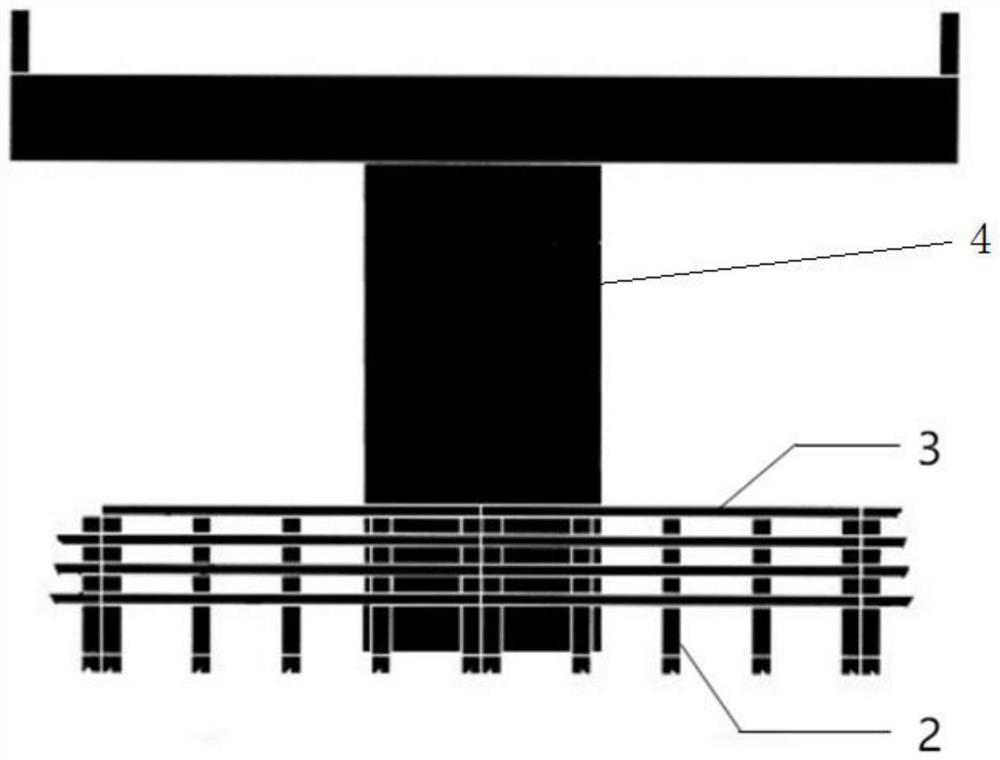

[0035] see figure 1 and figure 2 , this embodiment provides a bridge pier isolated composite material elastic anti-ship bending frame system, including:

[0036] Composite material protection pile 2, there are multiple composite material protection piles 2, and they are arranged in parallel on one side of the bridge pier;

[0037] A crossbeam 3, a plurality of crossbeams 3 are provided, and the crossbeam 3 is arranged on the composite material protection pile 2 for connecting multiple composite material protection piles 2, and the crossbeam 3 and the crossbeam 3 are arranged in parallel;

[0038] Among them, a plurality of composite protection piles 2 and a plurality of crossbeams 3 form a bent frame structure, and the composite protection piles 2 are made of fiber winding technology. The impact block is a cylindrical shell structure, and the cavity therein is filled with energy-dissipating particles.

[0039] Specifically, the continuous fiber filament 1 adopts one or mor...

Embodiment 2

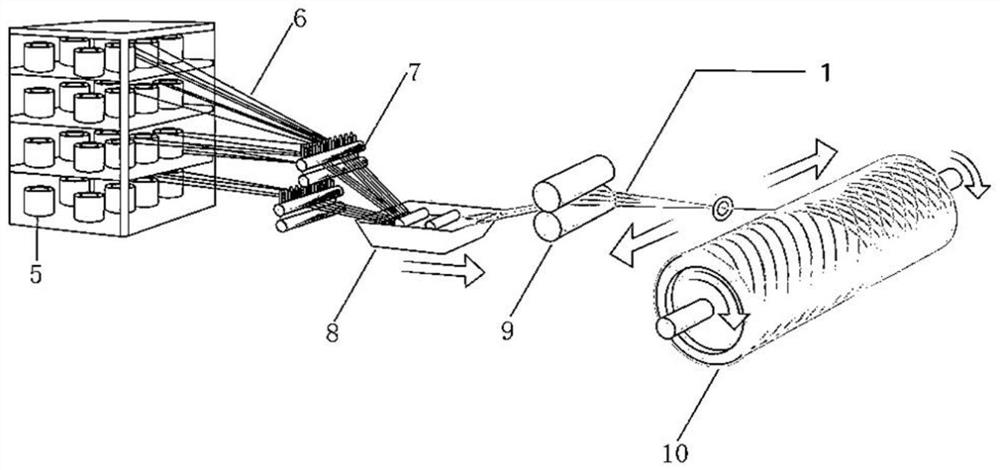

[0045] see image 3 , the present embodiment provides a method for preparing composite protection piles by fiber winding technology, which specifically includes:

[0046] Firstly, the fiber filament 6 wound on the creel 5 is passed through the separator 7, and then in the input resin tank 8, the fiber filament 6 is impregnated with an impregnating agent, and then the impregnated fiber filament 6 is processed by an embossing cylinder 9. embossing;

[0047] Then, the continuous fiber filaments 1 obtained after embossing are bundled into one strand through the guide rail, and then alternately wound layer by layer according to the angle of 45°, -45° or -45°, 45° with the rotating mandrel 10 Form a test piece;

[0048] Finally, the test piece is cured, and then the rotating mandrel 10 is removed to obtain the protective pile 2 made of composite material.

[0049] Specifically, the composite protection pile 2 provided by this embodiment has high energy absorption and has a certai...

Embodiment 3

[0052] see Figure 4 , the present embodiment provides a construction method of a bridge pier isolated composite material elastic anti-ship collision bent frame structure system, and the construction method includes the following steps:

[0053] Step S1, on one side of the bridge pier, a plurality of composite protection piles 2 are arranged in parallel;

[0054] Step S2 , installing multiple crossbeams 3 on the set multiple composite material protection piles 2 , and the crossbeams 3 are arranged in parallel with each other, and the multiple composite material protection piles 2 and the multiple crossbeams 3 form a bent frame system.

[0055] Specifically, in this embodiment, step S1 specifically includes:

[0056] Step S101, according to existing information, such as bridge drawings, design instructions, navigable ships, etc., determine the collision height of the ship;

[0057] Step S102, according to the soil data of the construction site or detailed geotechnical engineeri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com