Deep mine close-range ultra-thin protective layer mining arrangement structure and mining method

A technology for arranging structures and mining methods, which is applied in the ventilation of mines/tunnels, ground mining, mining equipment, etc. It can solve problems such as low permeability, safety assurance technology that does not meet high-efficiency production, and restrict high-yield and high-efficiency mines, so as to achieve air permeability increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

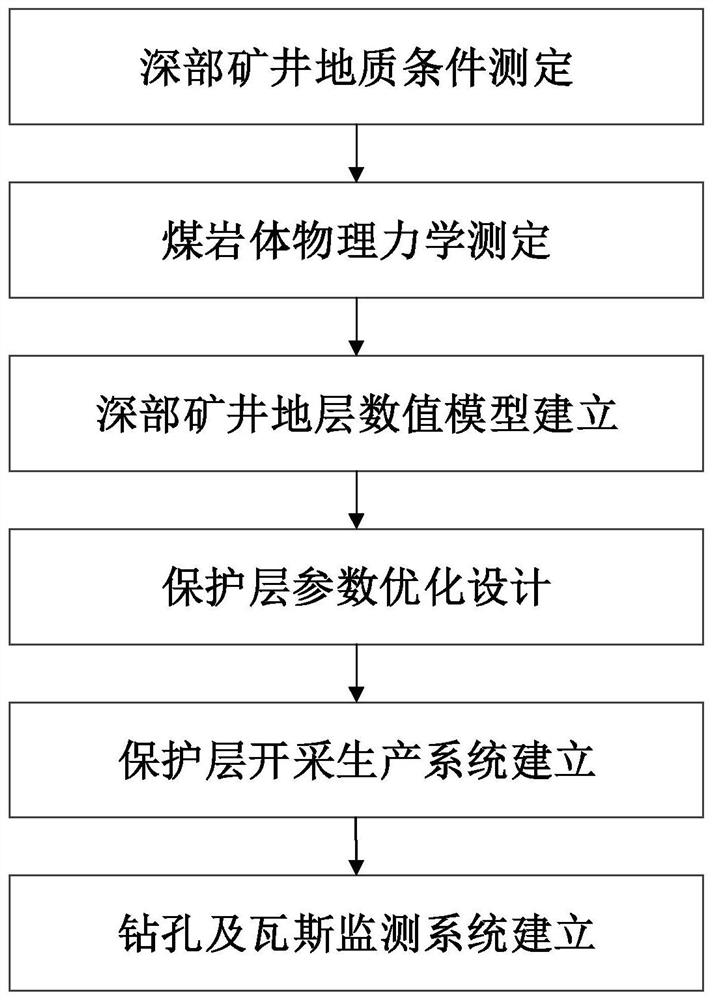

Method used

Image

Examples

Embodiment

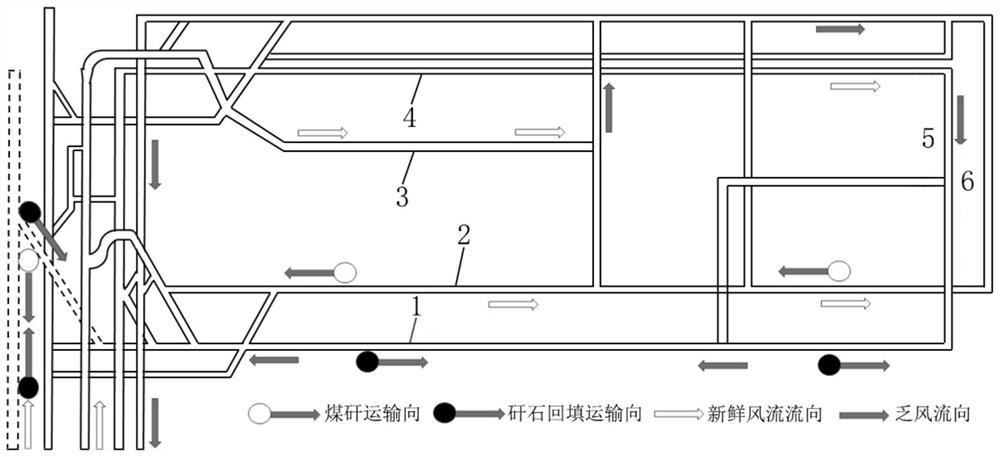

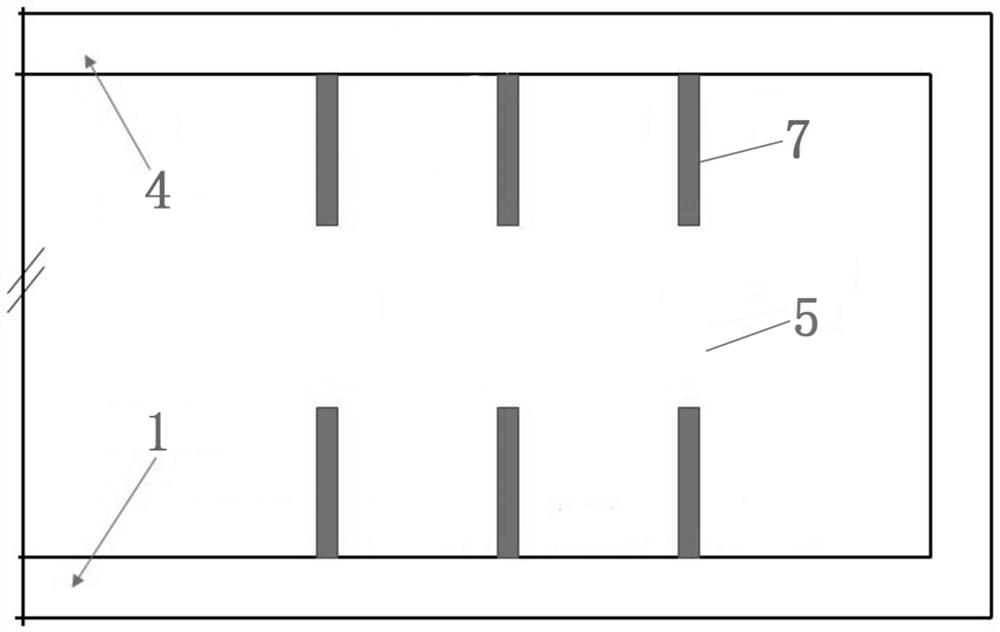

[0045] Such as figure 1 , figure 2Shown is a deep mine close-distance ultra-thin protective layer mining layout structure, including the protected layer return airway 1, the protective layer upper air inlet lane 2, the protective layer lower air inlet lane 3, the protected layer air inlet lane 4, the protected layer The layer cutout 5 and the protective layer inner cutout 6, the upper air inlet lane 2 of the protective layer and the lower air inlet lane 3 of the protective layer are located in the circulation body formed by the connection between the return air lane 1 of the protected layer and the air inlet lane 4 of the protected layer The upper or lower part, the cutout 6 in the protective layer is set on the upper or lower part of the cutout 5 in the protected layer; the working surface of the protective layer communicates with the upper air inlet lane 2 of the protective layer and the lower air inlet lane 3 of the protective layer through the inner cutout 6 of the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com