Supercritical carbon dioxide Brayton cycle system

A carbon dioxide and circulation system technology, applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of limited heat exchange and difficulty in meeting the heat recovery demand of the Brayton cycle system, and achieve overall changes with little impact and increased The method of heat recovery adjustment and the effect of meeting the demand of heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

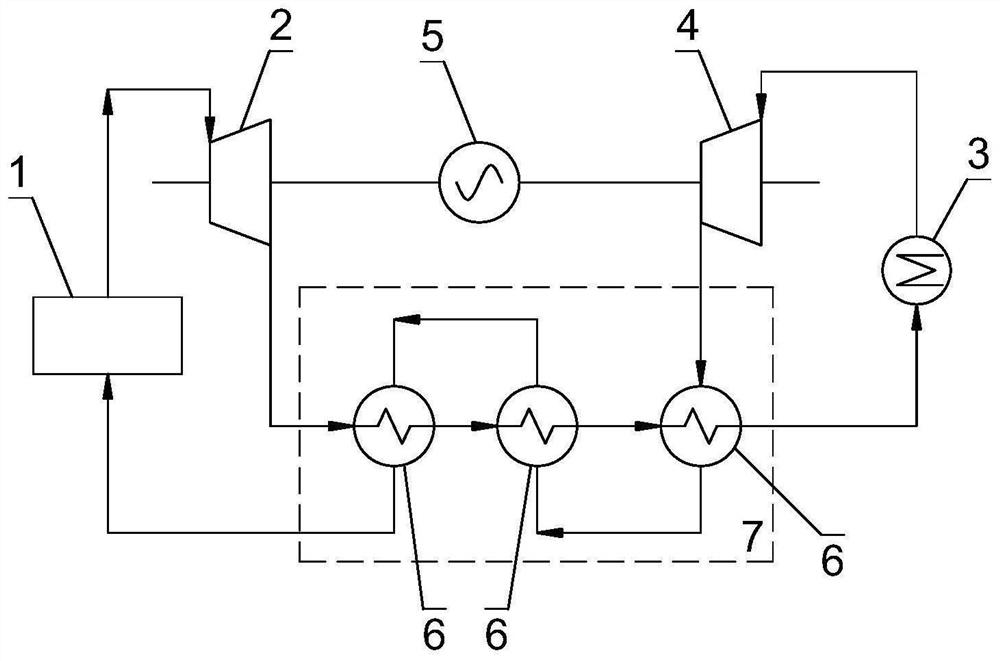

[0045] The first embodiment of the present invention provides a supercritical carbon dioxide Brayton cycle system, see figure 1 As shown, it includes heat source heat exchanger 1 , turbine 2 , cooler 3 , compressor 4 , generator 5 and regenerator 6 . Wherein, the heat source heat exchanger 1 , the turbine 2 , the cooler 3 and the compressor 4 are sequentially and cyclically connected, and the generator 5 is connected to the output end of the turbine 2 . The inlet and outlet of the hot side of the regenerator 6 are connected with the turbine 2 and the cooler 3 , and the inlet and outlet of the cold side are connected with the compressor 4 and the heat source heat exchanger 1 .

[0046] The supercritical carbon dioxide Brayton cycle system described in this embodiment uses supercritical carbon dioxide (hereinafter referred to as S-CO 2 ) is a closed thermodynamic cycle system of heat exchange and work medium. S-CO 2 Heat is absorbed at the heat source heat exchanger 1, and be...

Embodiment approach 2

[0087] The second embodiment of the present invention provides a supercritical carbon dioxide Brayton cycle system. The second embodiment is a further improvement on the first embodiment. Parts not specifically described include reference signs and text descriptions, which are the same as those in the first embodiment. An embodiment is the same, and will not be repeated here.

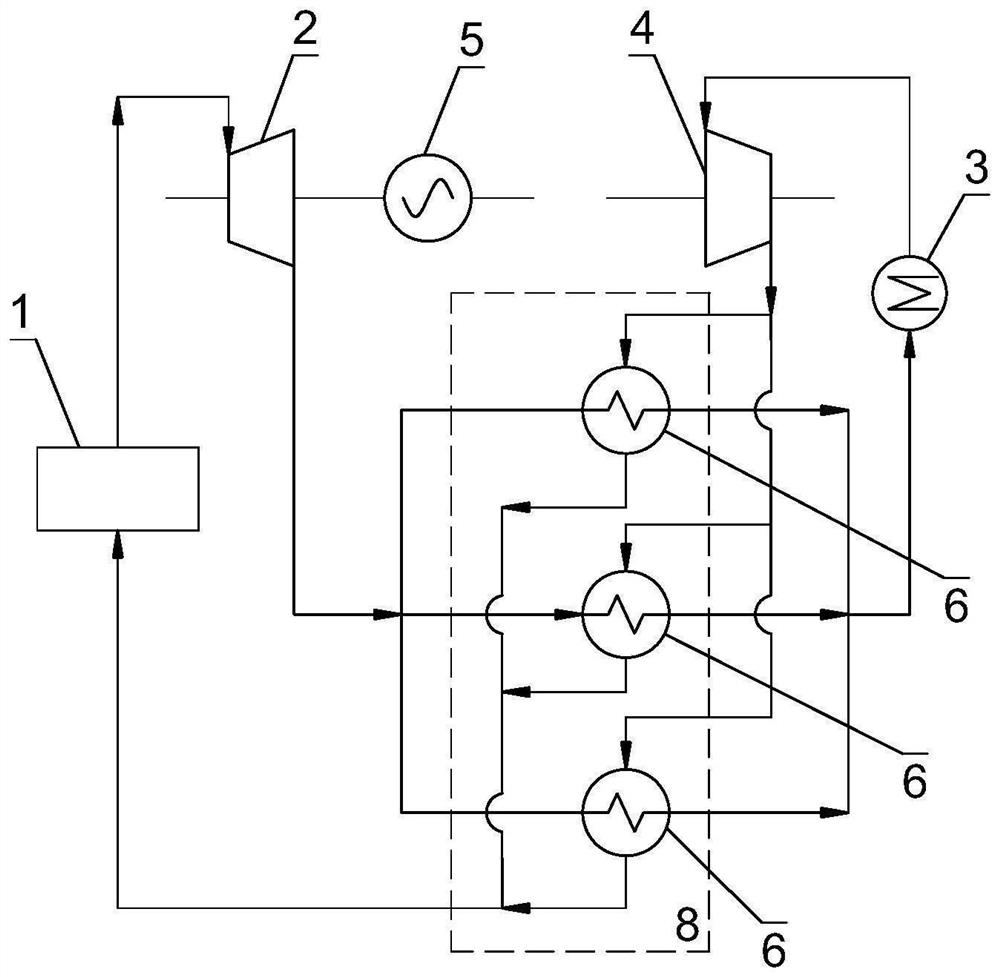

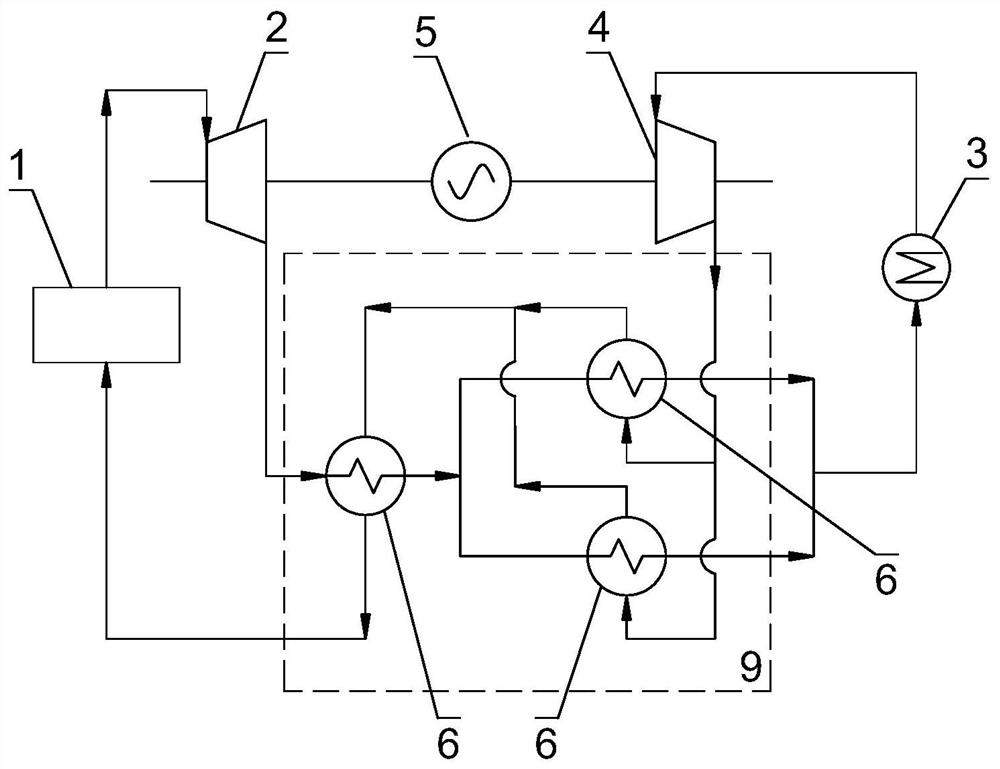

[0088] Compared with the first embodiment, the main improvement of the second embodiment is that in the second embodiment of the present invention, the basic combination of multiple regenerators 6 in the first embodiment is a module, and constitutes One or more regenerators 6 are connected to the modules. Connection modules can be as figure 1 A plurality of regenerators 6 connected in series form a series module 7, such as figure 2 A plurality of regenerators 6 connected in parallel form a parallel module 8, such as image 3 and Figure 4 A plurality of regenerators 6 in the middle series are respe...

Embodiment approach 3

[0097] The third embodiment of the present invention provides a supercritical carbon dioxide Brayton cycle system, the third embodiment is a further improvement on the first or second embodiment, and the parts not specifically described include reference signs and text descriptions, All are the same as those in the first or second embodiment, and will not be repeated here.

[0098] The main improvement of the third embodiment relative to the first or second embodiment is that in the third embodiment of the present invention, a plurality of regenerators 6 are provided to utilize other Possible ways in which heat source systems participate in regulation. combine Figure 11 It can be seen that the supercritical carbon dioxide Brayton cycle system also includes other heat source systems, and other heat source systems are used to participate in the variable load regulation of the Brayton cycle system. Preferably, the heat source system in this embodiment is the thermochemical rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com