Vertical pipeline mounting support for circular concrete column and mounting method

A technology for vertical pipelines and mounting brackets, which is applied in the directions of pipeline brackets, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of mechanical and electrical vertical pipeline installation methods, potential safety hazards of electromechanical pipelines, and difficulty in ensuring electromechanical pipelines. The effect of enhancing installation stability and service life, avoiding electrochemical corrosion, and improving the convenience of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

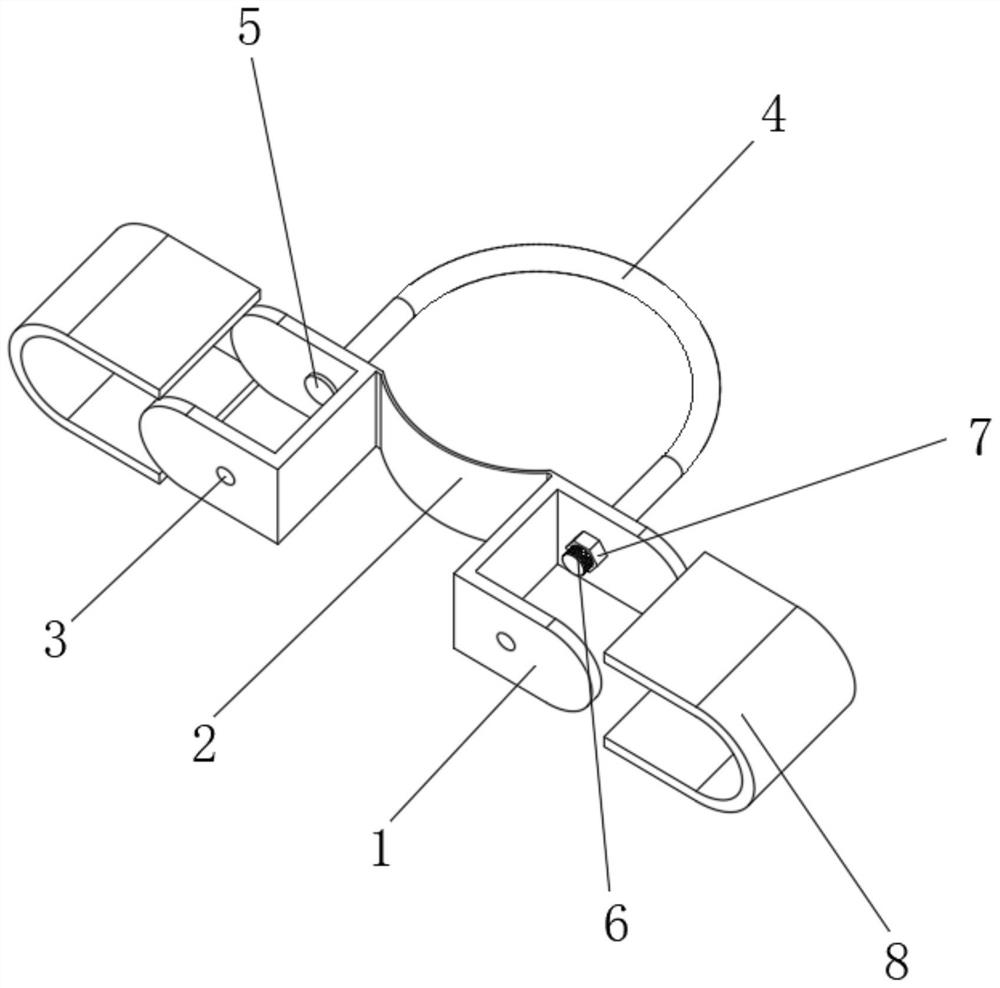

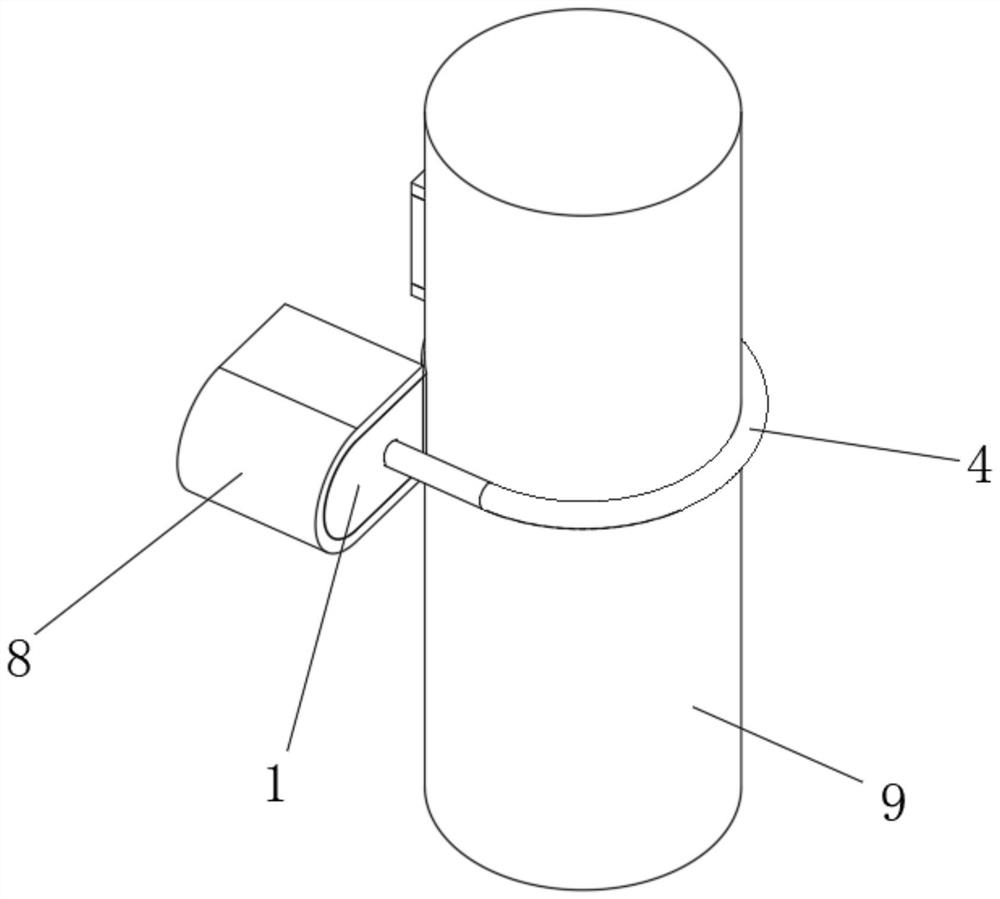

[0035] Such as Figure 1-Figure 2 As shown, this embodiment discloses a vertical pipe installation bracket for circular concrete columns, including two channel steels 1 for connecting with concrete columns, and the two channel steels 1 are supported by arcs The plates 2 are connected, and the arc-shaped support plate 2 can increase the overall contact area between the rainwater pipe 9 and the support, improve the friction between the support and the rainwater pipe 9, enhance the installation stability and service life of the rainwater pipe 9, and cooperate with the arc-shaped support plate 2 The annular hoop used to hold the rainwater pipe 9, the annular hoop in this embodiment uses a galvanized through wire 4, which itself has a certain flexibility, which is convenient for it to pass through two channel steels 1, and the galvanized through wire 4 itself has a certain degree of flexibility. One end of the wire 4 is clamped with the channel steel 1 through the baffle plate 5 fi...

Embodiment 2

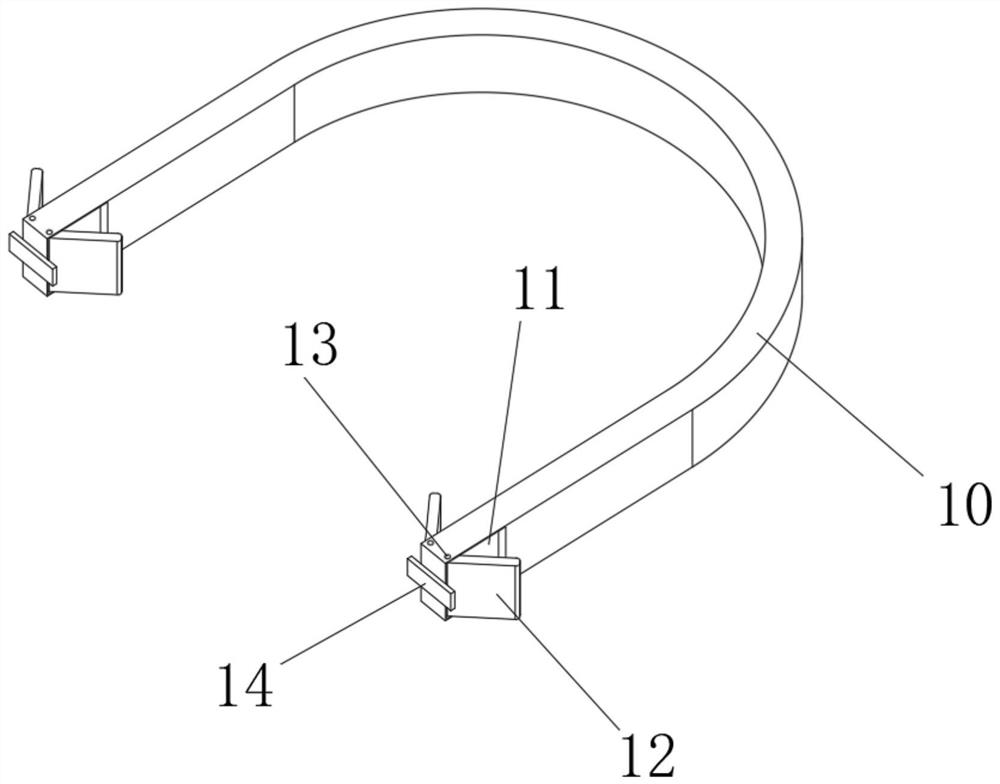

[0038] Such as Figure 3-Figure 7 As shown, this embodiment discloses a vertical pipe installation bracket for circular concrete columns. This embodiment adopts the same inventive concept as Embodiment 1, and the difference between it and Embodiment 1 is that this implementation The annular hoop in the example is selected U-shaped steel band 10, and the two ends of U-shaped steel band 10 are all provided with two receiving grooves 11, and the two receiving grooves 11 of each end are opened symmetrically on the two side walls of U-shaped steel band 10, The inside of each storage groove 11 is also connected with a rotating plate 12 through the elastic rotation of the torsion spring 13, and the torsion spring 13 is located in the storage groove 11 on the side near the end of the U-shaped steel belt 10, and the two ends of the U-shaped steel belt 10 are also fixedly connected. There is a support limit plate 14 used to limit the rotation of the rotating plate 12, and the U-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com