Axial non-coupling water spaced charging structure and smooth blasting method using same

A technology of interval charge and smooth surface blasting, which is applied in the field of blasting, can solve the problems of increased drilling cost, large damage to the pre-retained rock mass, and large blasting vibration, so as to reduce the generation of blasting dust, reduce the frequency of blasting vibration, The effect of reducing peak pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

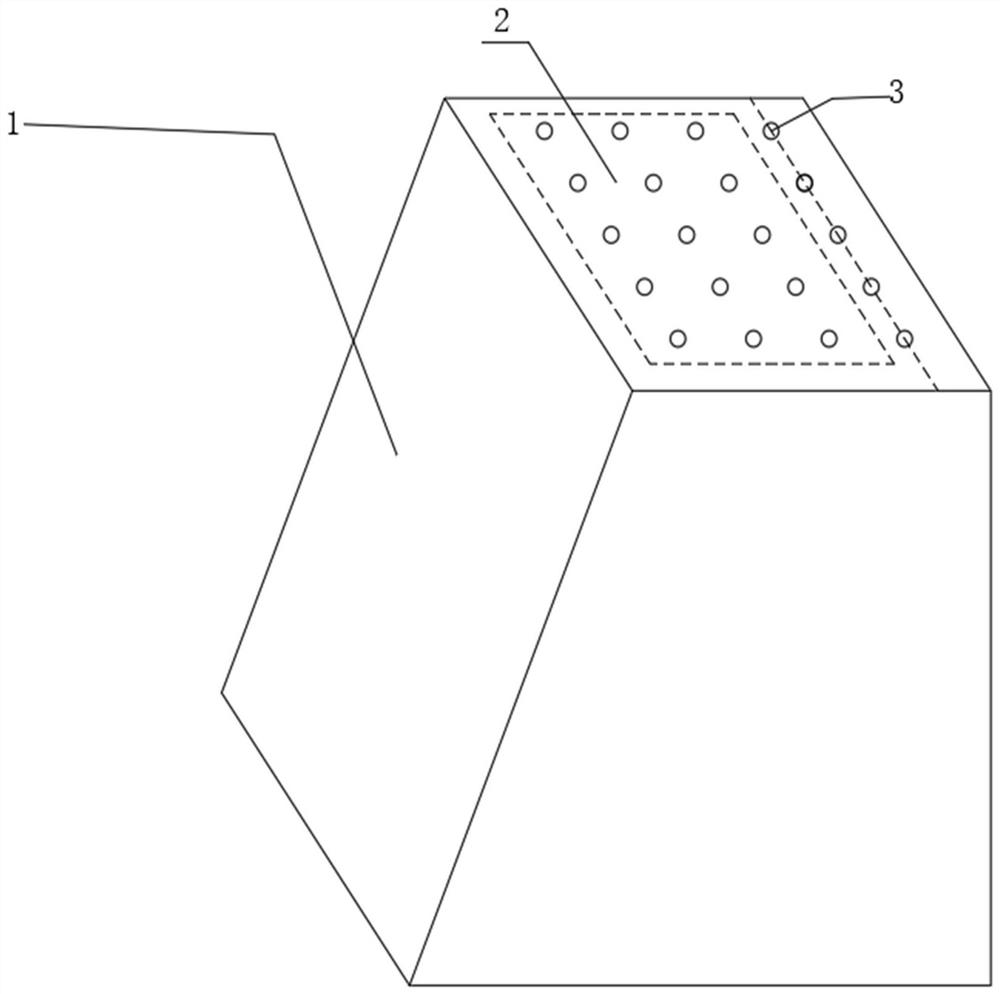

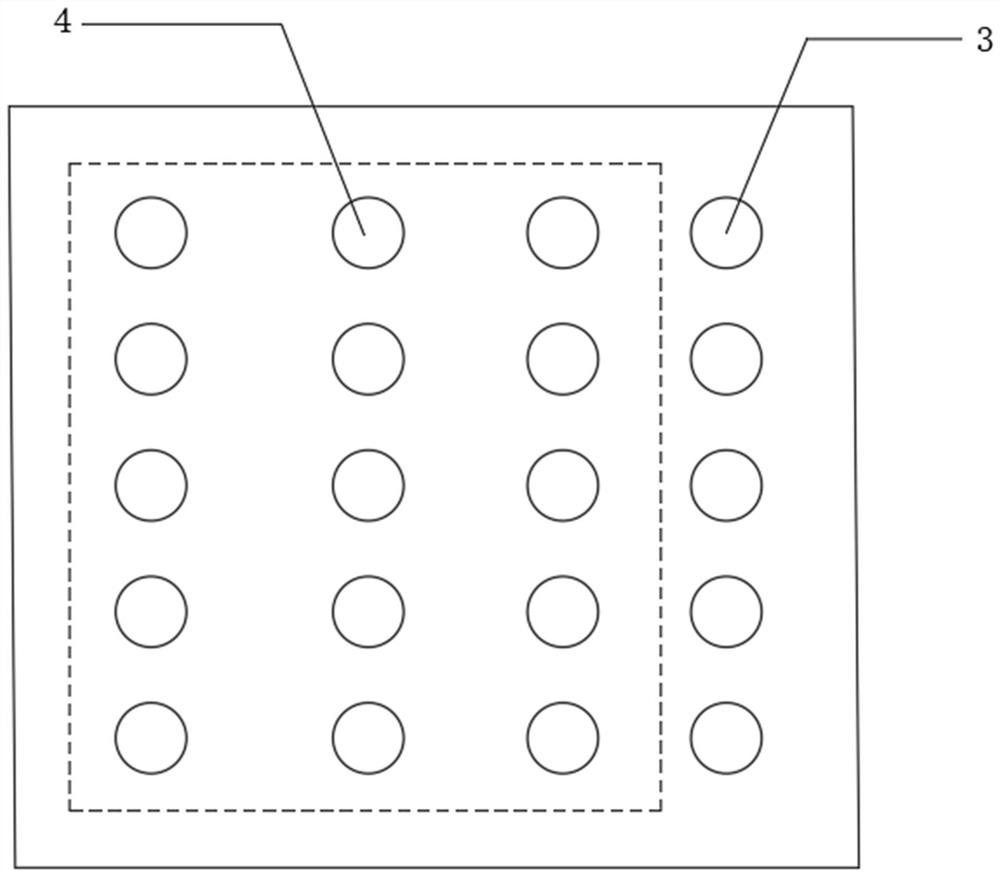

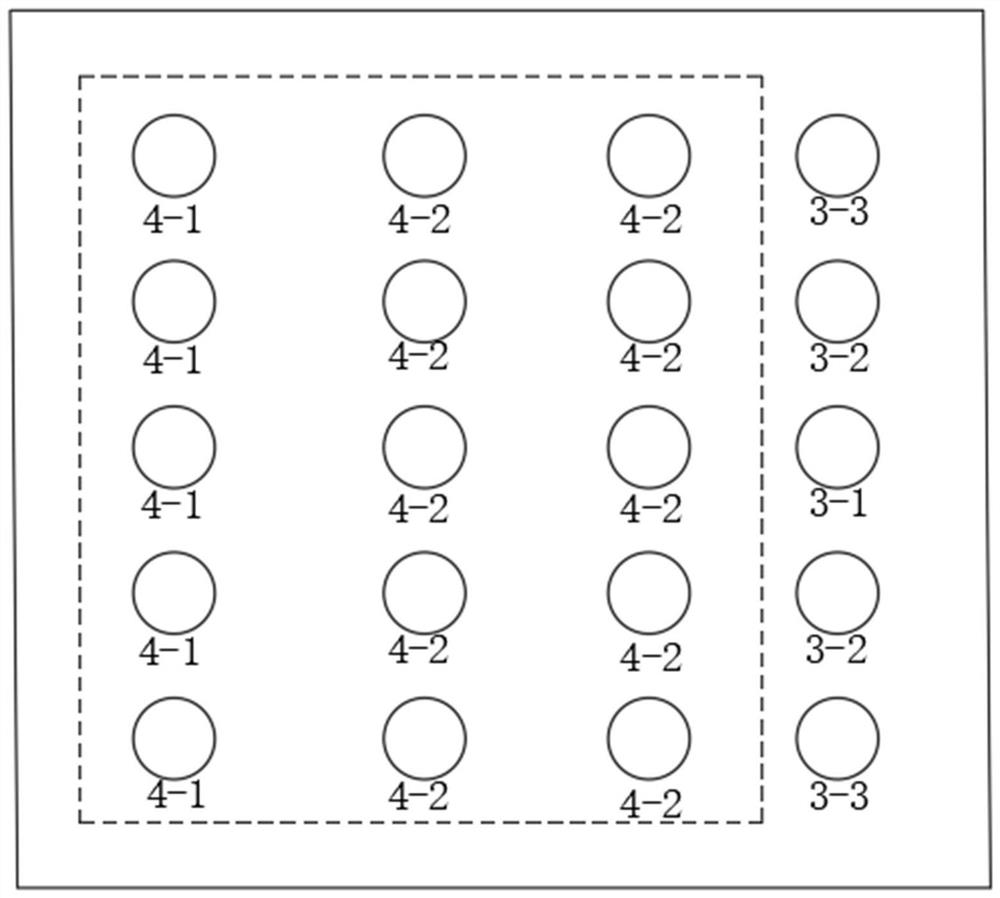

[0026] Example 1: The Figure 1-4 Shown uncoupled An axial space blasting water, comprising a tubular bag I12 of, drug volume 11, the tubular bag II9, stemming 8, detonating cord 7; blasthole substrate placed I12 of the tubular bag, the tubular I12 drug volume water bag 11 connected to the tip, drug volume 10 or 11 on both sides of the air gun is coupled with the hole wall, drug volume 11 using direct air radially decouple charge coupled or radial air charge, the distal end 11 drug volume II9 tubular bag is connected, the distal end of the tubular bag made from II9 stemming obturator 8, the entire blast hole 7 through the detonating cord 11 to the bottom of the drug volume.

[0027] The present invention employs an axial decoupling space blasting water provided by hole initiation of detonation in the network environment slope excavation required for accurate initiation by extension of the digital electronic control detonator, after explosion, the walls can slope semi-hole is prefer...

Embodiment 2

[0047] Example 2: Construction of the environment of the present embodiment and the construction standards different from Example 1.

[0048] In this embodiment with the standard required by the construction method of the center to both sides of the smooth blasting detonating sequentially consistent in Example 1, except that: the optical aperture 3 borehole diameter 45mm, pitch of 60cm; hole main borehole 4 having a diameter of 75mm, pitch of 70cm, row distance of 110cm. The presence of the excavation walls slope at an angle with the ground, belonging to the slope of the inclined wall. According to the construction requirements, slope excavation contour is in the form of an arc, so that the borehole is arranged as a light arc, arc 80 °, due to the high slope excavation, 4 hole main borehole depth reaches 11m, light 3 hole borehole depth is 10m. And a light main borehole 4 drilled boreholes 3 are angled, the main borehole 4 80 ° angle with the ground, the light popping 3 70 ° angle...

Embodiment 3

[0049] Example 3: adjusting the light borehole 3, charge structure of the main borehole 4, reducing the peak pressure during blasting of the hole wall.

[0050] Examples of this slope excavation smooth blasting method is substantially the same as in Example 1, except that: the optical aperture 3 borehole diameter 30mm, pitch of 30cm; 4 hole main borehole diameter of 50mm, pitch is 50cm, row spacing is 100cm. At the same time the main blasting initiation region 2 is, the same sequence as in Example 3 borehole light initiation, delay time between the holes is 10ms. Contour line slope in the presence of a certain curvature, was 15 °, the main borehole 4 is more perpendicular to the ground, the ground was 70 ° angle, contribute to the formation of the inclined wall slope, slope light formed borehole 3 Stablize. Decoupling charge structure in this example as Figure 4 , The drug is not coupled to the air volume in the presence of light borehole 3 in the radial direction, so that is more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com