Method for measuring service life of electrochemical sensor through pulse excitation

A pulse excitation, electrochemical technology, applied in scientific instruments, instruments, measuring devices, etc., can solve the problem of sensor life evaluation and diagnosis methods without relevant technical solutions, and achieve the effect of improving work reliability and stability, and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

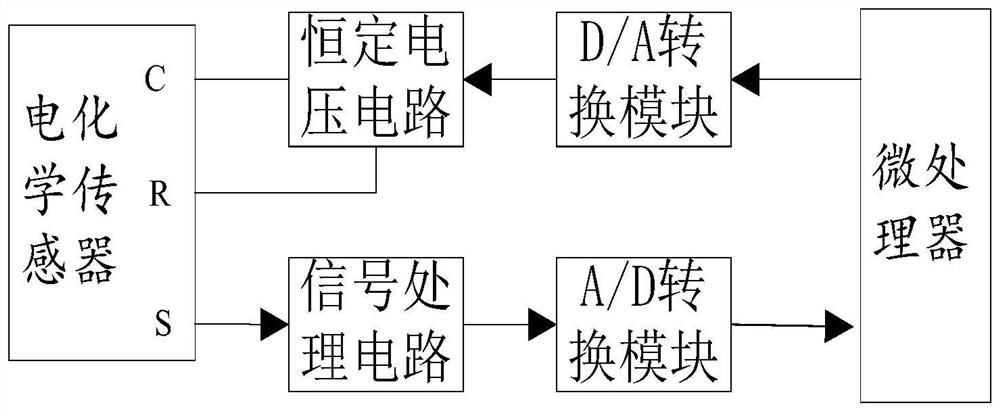

[0042] GTH1000 carbon monoxide sensor for mine uses the carbon monoxide gas sensor of electrochemical principle as the sensitive element. Through the analysis of a large number of samples, the voltage amplitude UI of the key parameters of the pulse excitation is set to 3mV and the pulse width T1 is 100ms; the microprocessor controls the constant voltage UR between the reference electrode (R) and the counter electrode (C) of the electrochemical sensor to be 1100mV, the output current signal of the detection electrode (S) of the electrochemical sensor is 150nA, the output voltage UO of the current signal is 1101.5mV after the signal processing circuit, UO enters the A / D conversion circuit, and the microprocessor reads the A / D conversion result D0 in real time For 1503, the carbon monoxide gas concentration is measured.

[0043] The microprocessor starts the timer, sends the excitation pulse, and the microprocessor reads the A / D conversion result in real time every sampling time ...

Embodiment 2

[0047] GTH1000 carbon monoxide sensor for mine uses the carbon monoxide gas sensor of electrochemical principle as the sensitive element. Through the analysis of a large number of samples, the voltage amplitude UI of the key parameters of the pulse excitation is set to 3mV and the pulse width T1 is 100ms; the microprocessor controls the constant voltage UR between the reference electrode (R) and the counter electrode (C) of the electrochemical sensor to be 1100mV, the output current signal of the detection electrode (S) of the electrochemical sensor is 150nA, the output voltage UO of the current signal is 1101.5mV after the signal processing circuit, UO enters the A / D conversion circuit, and the microprocessor reads the A / D conversion result D0 in real time For 1503, the carbon monoxide gas concentration is measured.

[0048] The microprocessor starts the timer, sends the excitation pulse, and the microprocessor reads the A / D conversion result in real time every sampling time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com