Dynamic soft measurement method for thickness of blank shell of continuous casting blank

A continuous casting slab and soft measurement technology, applied in the field of steelmaking and continuous casting, can solve the problems of waste products, low data accuracy, limited prediction area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

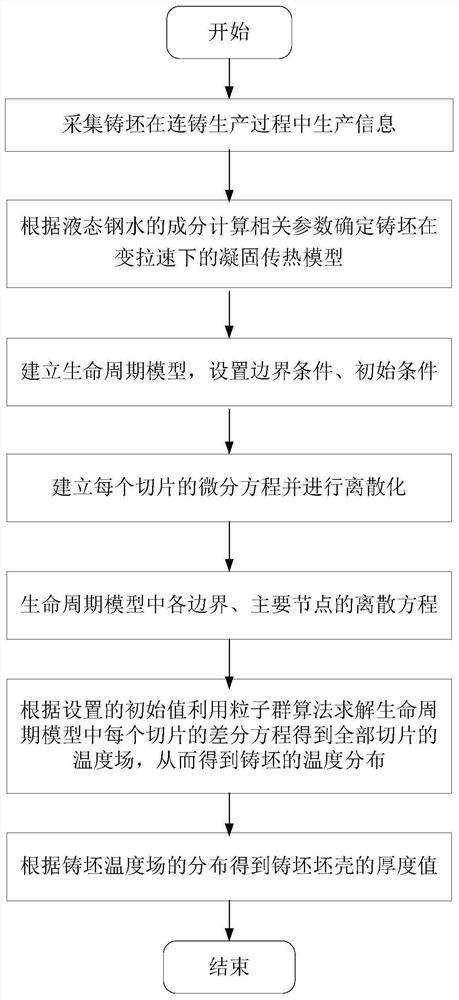

[0086] Such as figure 1 As shown, a dynamic soft measurement method for the shell thickness of continuous casting slab, including:

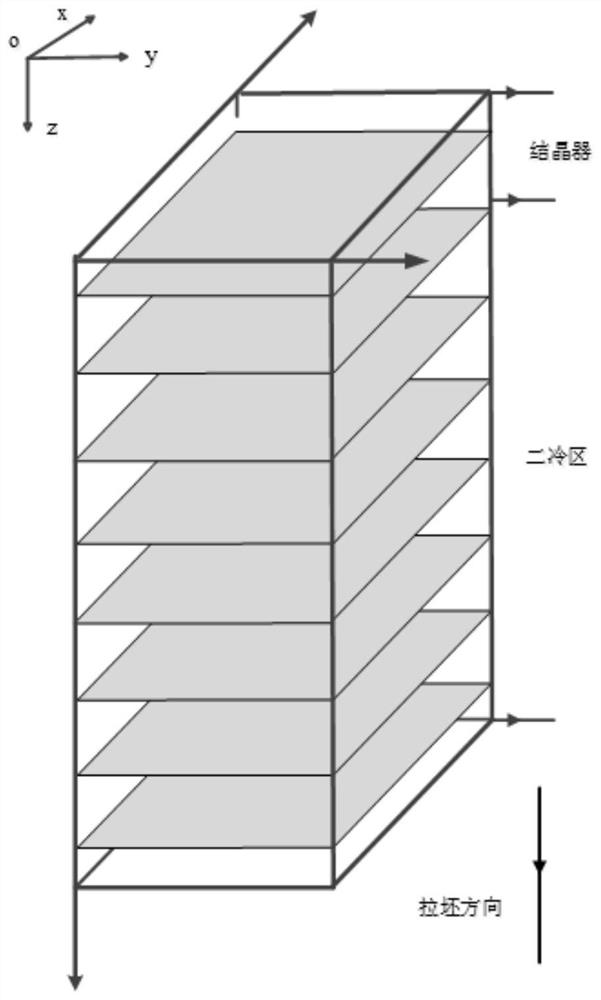

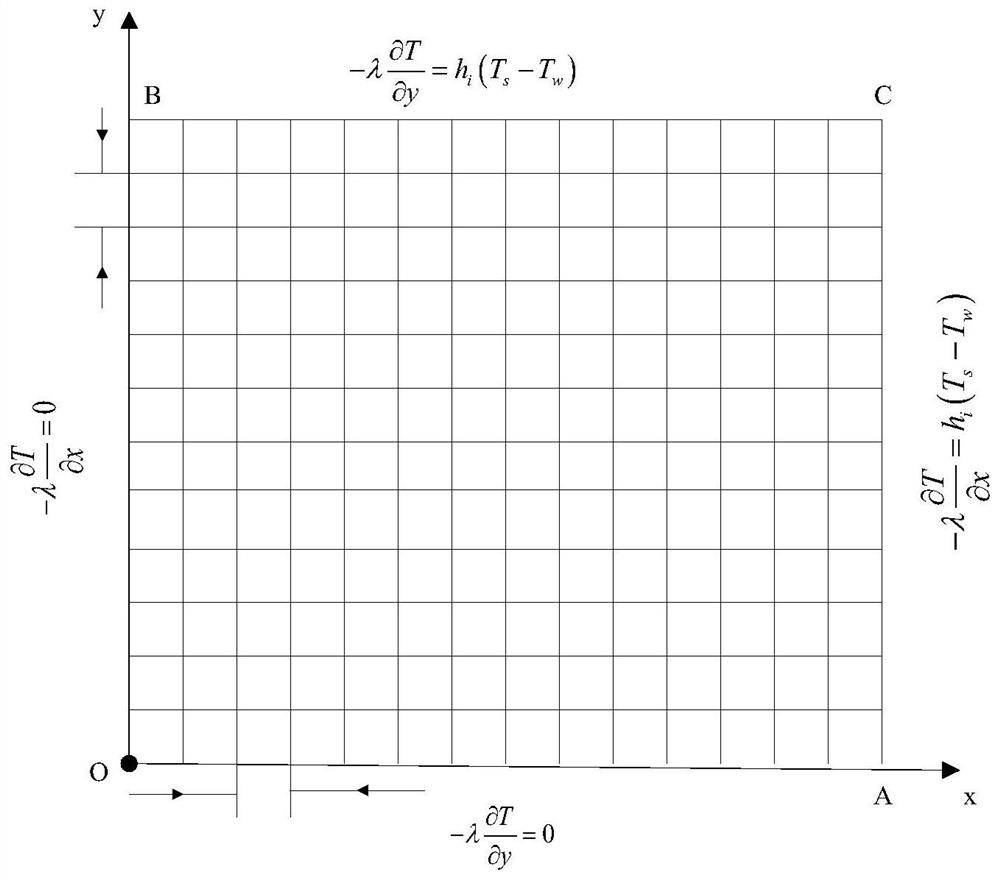

[0087] Step 1: Collect the production information of the slab in the continuous casting production process, the production information includes the parameters of the continuous casting machine equipment, the composition of the liquid steel, and the thermal physical parameters of the slab; the continuous casting machine equipment in the step 1 The parameters include the metallurgical length of the continuous casting machine, the casting speed, the geometric size of the crystallizer, the number of segments in the secondary cooling zone of the continuous casting machine (that is, the air cooling stage), the amount of water sprayed in each segment; the thermal physical properties of the slab The parameters includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com