Power distribution room switch cabinet temperature and humidity control system

A humidity control system and power distribution room technology, applied in control/regulation systems, non-electric variable control, substation/switch layout details, etc. Solve the effect of slow heat dissipation and speed up heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

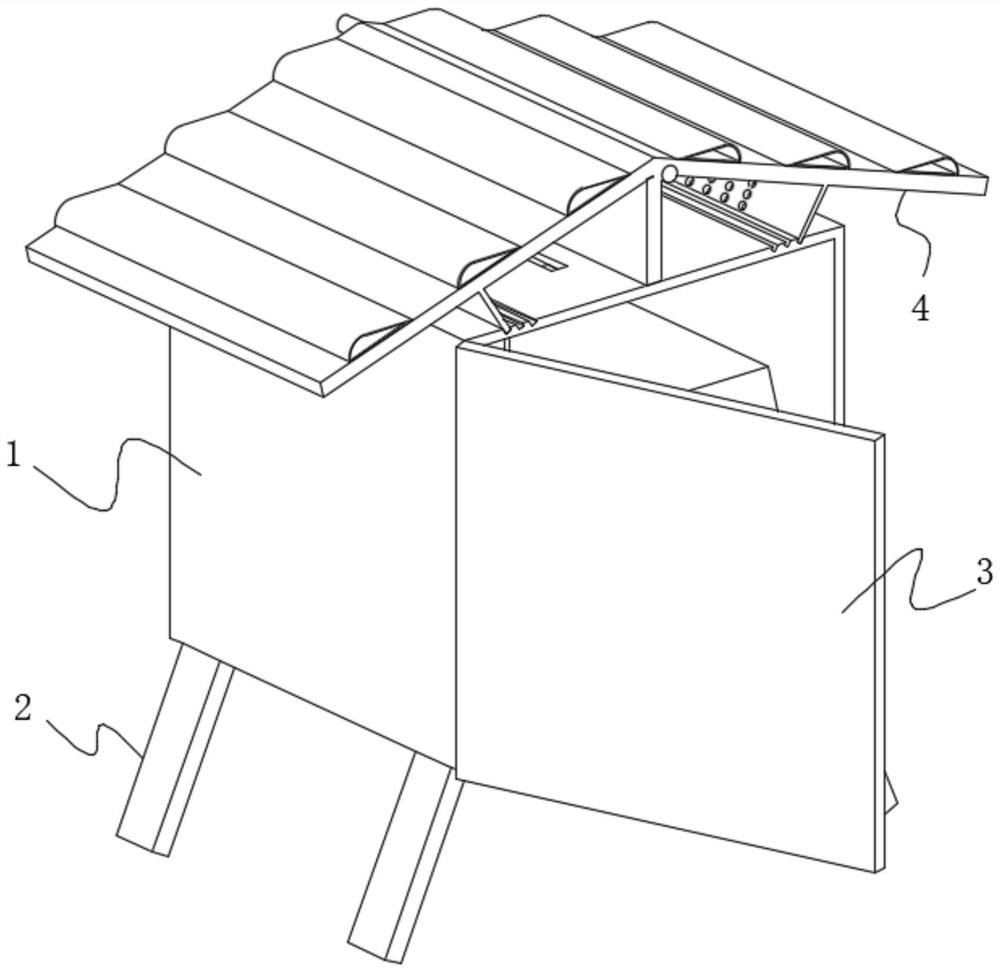

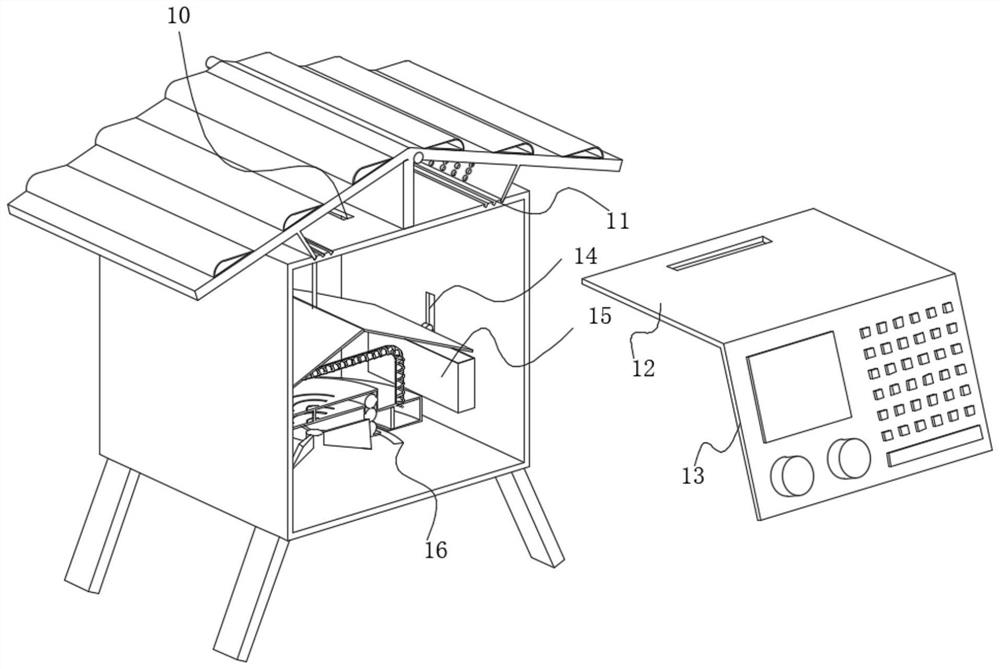

[0029] use Figure 1-Figure 6 A temperature and humidity control system for a switch cabinet in a power distribution room according to an embodiment of the present invention will be described as follows.

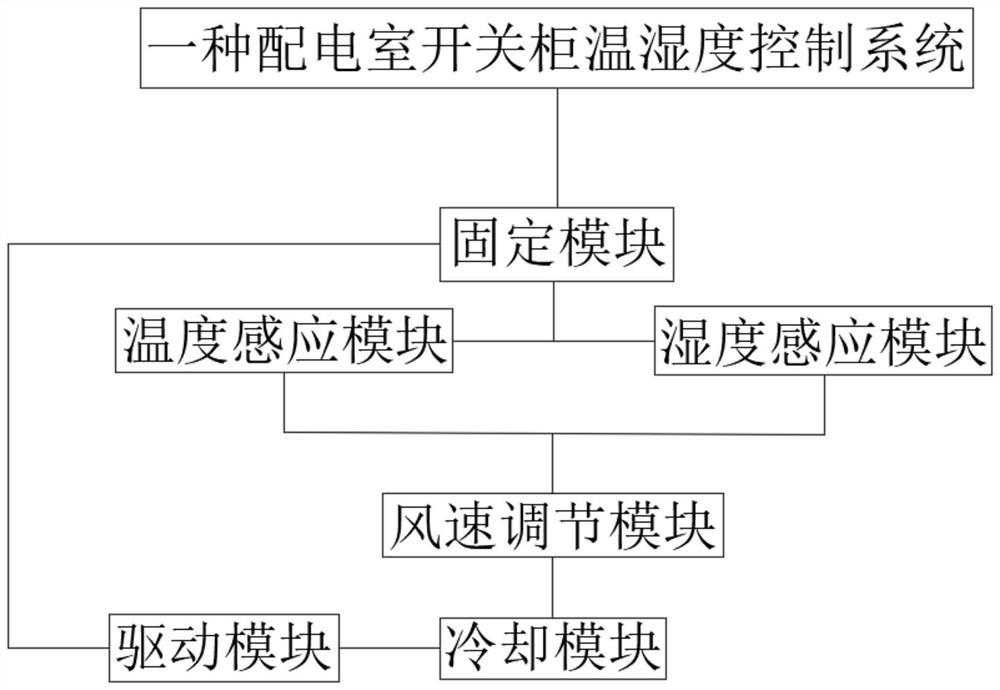

[0030] Such as Figure 1-Figure 6 As shown, a switch cabinet temperature and humidity control system in a power distribution room of the present invention includes a temperature sensing module; it also includes a humidity sensing module, a wind speed adjustment module, a driving module, a cooling module and a fixing module, wherein:

[0031] Humidity sensing module: monitor the air humidity inside the switch cabinet in real time to avoid circuit short circuit due to high humidity inside the equipment.

[0032] Temperature sensing module: monitor the temperature inside the switchgear in real time. Together with the humidity sensing module, when the internal temperature of the device exceeds the threshold, an alarm will be sent from the outside of the device, and the internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com