Method for preparing flaxseed protein crisps by taking flaxseed as raw material

A flaxseed protein and flaxseed technology, which is applied to the protein composition of vegetable seeds, protein food ingredients, dough treatment and other directions, can solve the problems of complicated preparation methods, brittle and loose protein, low efficiency, etc., and it is not easy to loosen and fall off. The effect of slag, taste improvement and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

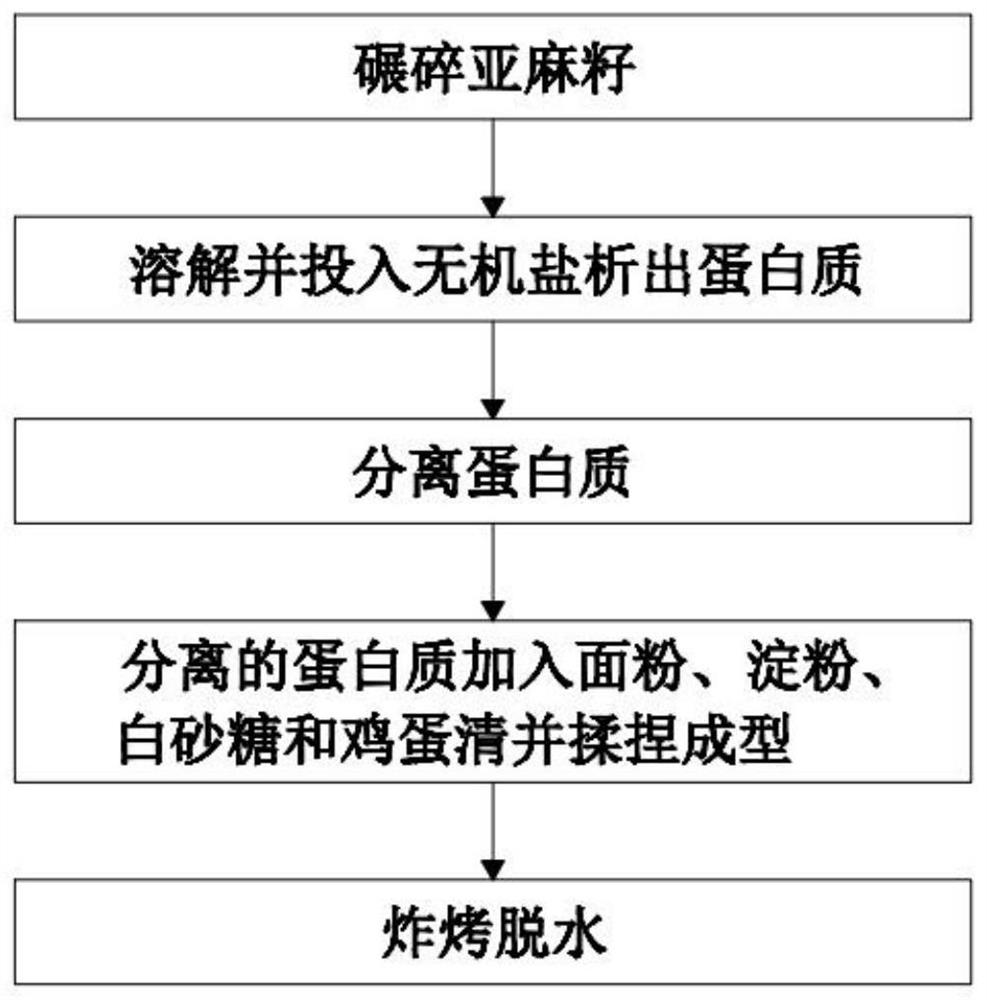

[0027] see figure 1 , the present invention provides a technical solution: a method for preparing linseed protein brittle using linseed as raw material, the specific steps of the method for preparing linseed protein brittle using linseed as raw material are as follows:

[0028] S1: Crushed flaxseed: Wash the flaxseed, press the washed flaxseed through an oil press, and discharge a large amount of fat components in the flaxseed by squeezing the oil press, and during the extrusion process , heating the linseed at 50 degrees Celsius, and obtaining the linseed cake after oil extraction, and crushing the linseed cake into powder;

[0029] The linseed cake crushing method is as follows: obtain the linseed cake, heat the linseed cake, stir and pulverize the linseed cake with a stirring device, sieve, filter the large particle material in the pulverized linseed cake and continue to pulverize, The heating temperature is 40 degrees Celsius, and the heating, stirring and crushing time i...

Embodiment 2

[0040] see figure 1 , the present invention provides a technical solution: a method for preparing linseed protein brittle using linseed as raw material, the specific steps of the method for preparing linseed protein brittle using linseed as raw material are as follows:

[0041] S1: Crushed flaxseed: Wash the flaxseed, press the washed flaxseed through an oil press, and discharge a large amount of fat components in the flaxseed by squeezing the oil press, and during the extrusion process , heating the linseed at 55 degrees Celsius, and obtaining the linseed cake after oil extraction, and crushing the linseed cake into powder;

[0042] The linseed cake crushing method is as follows: obtain the linseed cake, heat the linseed cake, stir and pulverize the linseed cake with a stirring device, sieve, filter the large particle material in the pulverized linseed cake and continue to pulverize, The heating temperature is 42.5 degrees Celsius, and the heating, stirring and crushing time...

Embodiment 3

[0053] see figure 1 , the present invention provides a technical solution: a method for preparing linseed protein brittle using linseed as raw material, the specific steps of the method for preparing linseed protein brittle using linseed as raw material are as follows:

[0054] S1: Crushed flaxseed: Wash the flaxseed, press the washed flaxseed through an oil press, and discharge a large amount of fat components in the flaxseed by squeezing the oil press, and during the extrusion process , heating the linseed to 60 degrees Celsius, and obtaining the linseed cake after oil extraction, and crushing the linseed cake into powder;

[0055] The linseed cake crushing method is as follows: obtain the linseed cake, heat the linseed cake, stir and pulverize the linseed cake with a stirring device, sieve, filter the large particle material in the pulverized linseed cake and continue to pulverize, The heating temperature is 45 degrees Celsius, and the heating, stirring and crushing time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com