Novel composite ceramic foam filter

A technology of ceramic filter and composite foam, which is applied in the direction of filtration separation, chemical instruments and methods, and improvement of process efficiency. Good effect, not easy to drop slag, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

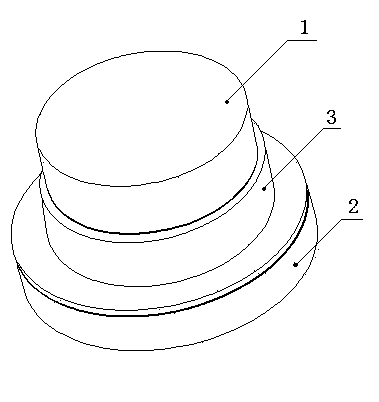

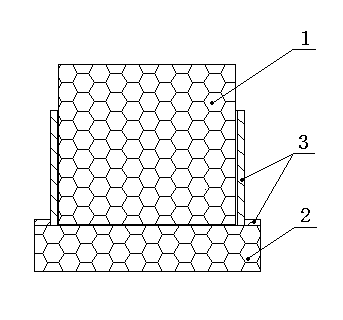

[0019] The small filter 1 is a 20ppi alumina ceramic filter with a diameter of 49mm and a thickness of 48mm;

[0020] The large filter 2 is a 20ppi alumina ceramic filter with a diameter of 74mm and a thickness of 12mm;

[0021] The high-temperature-resistant wrapping layer 3 is high-temperature-resistant fiber paper made of aluminum silicate with a width of 30 mm and a thickness of 3 mm.

Embodiment 2

[0023] The small filter 1 is a 30ppi zirconia ceramic filter with a diameter of 47mm and a thickness of 28mm;

[0024] The large filter 2 is a 30ppi zirconia ceramic filter with a diameter of 68mm and a thickness of 15mm;

[0025] The high-temperature-resistant wrapping layer 3 is a high-temperature-resistant fiber made of alumina with a width of 20 mm and a thickness of 3 mm.

[0026] The invention not only has the filtering effect of a filter, but also does not introduce impurities such as iron, and at the same time, it is not easy to drop slag during use, is strong and durable, has the characteristics of high strength and good filtering effect, and has great promotional significance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com