Axial vibration type oil-water separator

A technology of oil-water separator and axial vibration, which is applied in the direction of filtration separation, separation method, immiscible liquid separation, etc., and can solve problems such as low processing efficiency, long processing time, and human health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

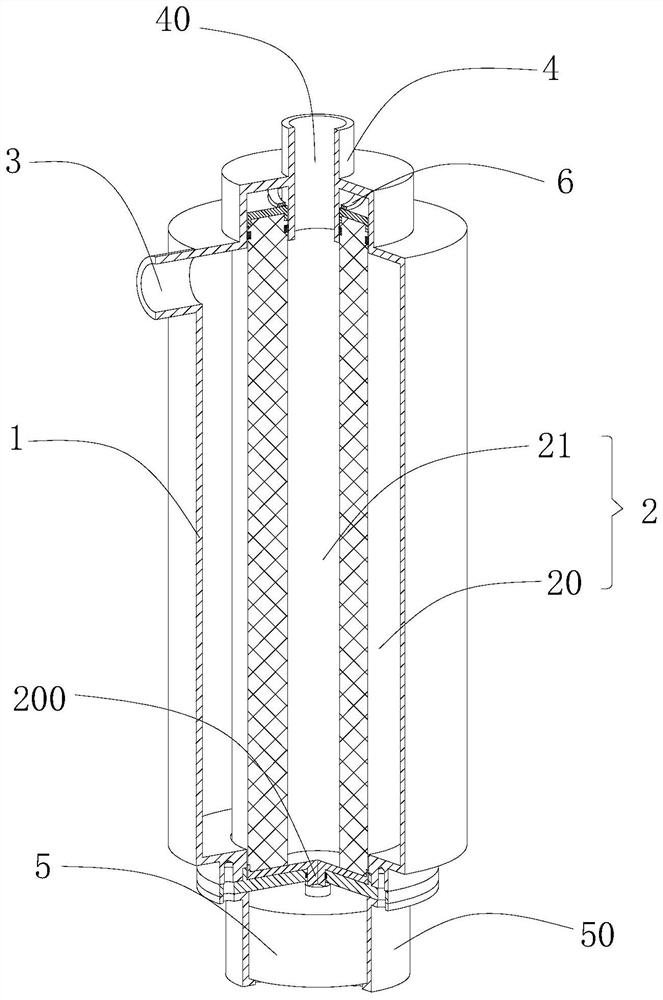

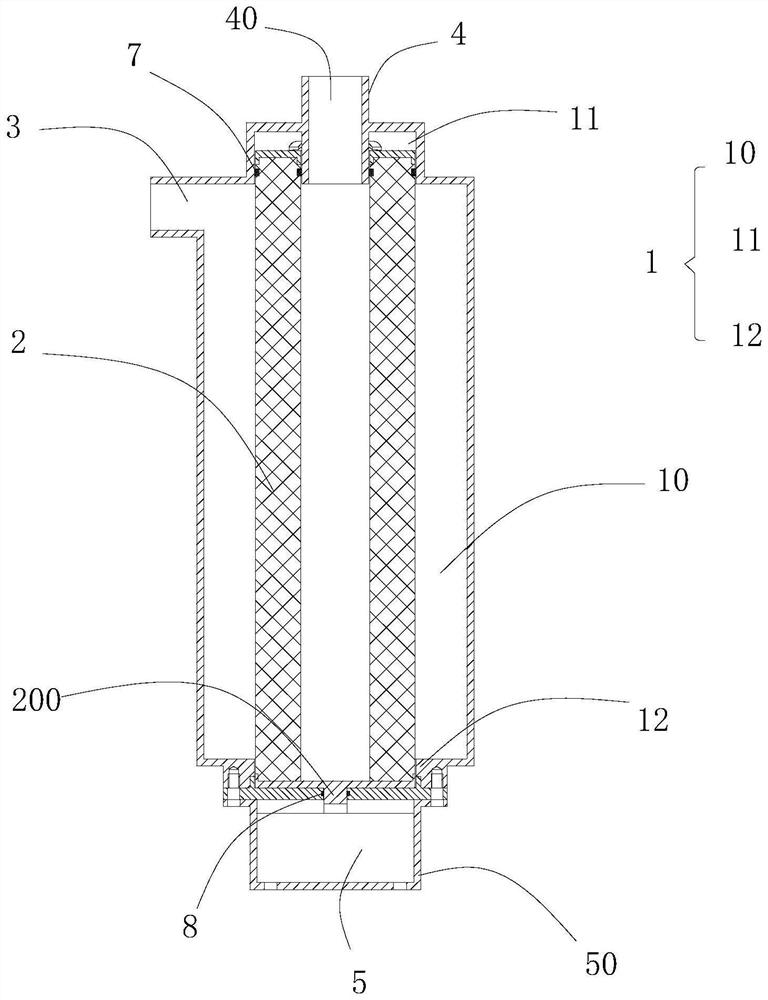

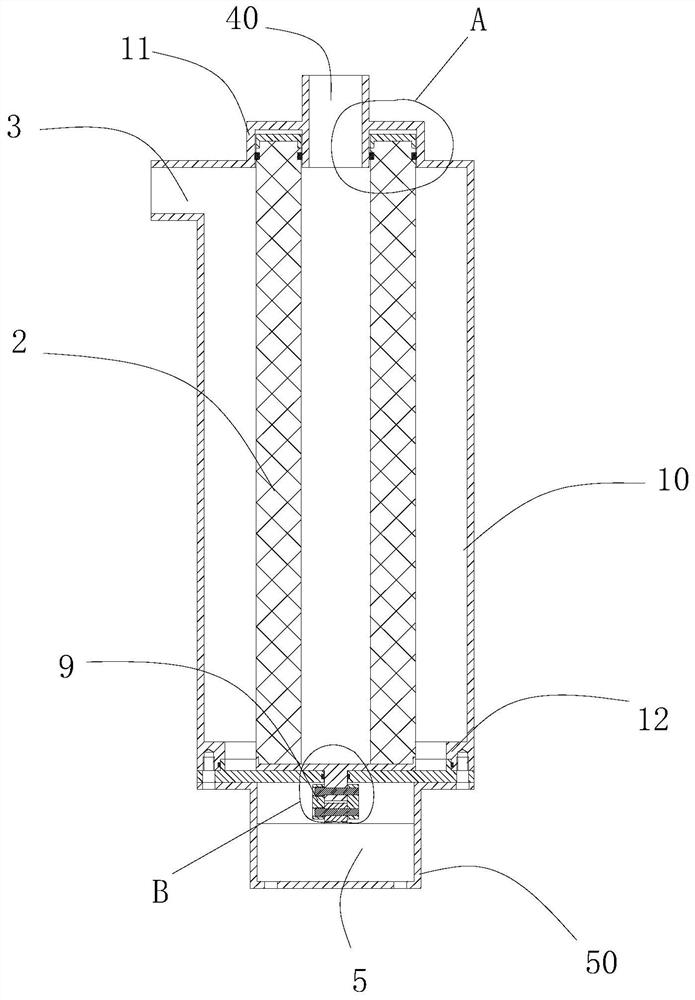

[0039] See Figure 1-10 , the present invention shows an axial vibrating oil-water separator, including a housing 1, a filter core 2 and a vibrating device 5, the housing 1 is a hollow structure, and the filter core 2 is arranged in the shell Inside the body 1, and the filter core body 2 is connected to the vibration device 5 to drive the filter core body 2 to vibrate axially; the vibration device 5 is preferably a vibration motor, and the vibration motor drives the filter core body 2 to perform axial vibration. vibration.

[0040] The housing 1 is provided with an inlet 3, so that the liquid to be filtered enters the housing 1 from the inlet 3, and the filter core 2 is formed with an inner cavity 21 and a filter hole communicating with the inner cavity 21 (not shown), the filter core 2 is sealed with the housing 1 so that the liquid entering from the inlet 3 can only enter the inner cavity 21 through the filter hole. That is, after the oily water is filtered through the fil...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap