Ultrasonic crushing device

A pulverizing device and ultrasonic technology, applied in the direction of grain processing, etc., can solve the problems of automatic stabilization of cell storage cups without cell solution, inaccurate test results, and inability to isolate and protect the cell storage cups, etc., to increase the diversity of use. and convenience, improve the stability and safety of use, improve the effect of convenience and efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

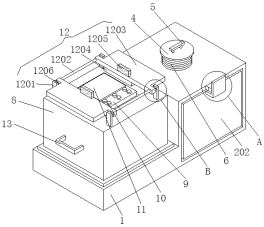

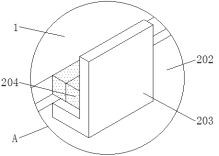

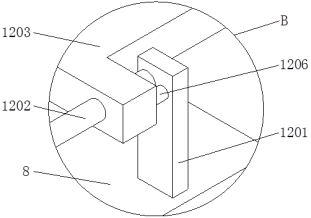

[0036] Such as Figure 1-Figure 8 As shown, an ultrasonic crushing device includes a device housing 1 and an ultrasonic transducer 4, a sound insulation protection component 2 is installed on the device housing 1, an automatic clamping and limiting mechanism 3 is installed in the device housing 1, and the ultrasonic transducer 4 A threaded body 6 is provided on the top, and the ultrasonic transducer 4 is threadedly connected to the top of the device housing 1 through the threaded body 6. A fixed handle 5 is welded and fixed on the top surface of the ultrasonic transducer 4, and the bottom bolt of the ultrasonic transducer 4 An ultrasonic crushing head 7 is installed, and a control host 8 is welded and fixed on the device shell 1;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com