Multifunctional machining platform for steel structure design and machining

A processing platform and multi-functional technology, applied in the field of steel structure, can solve the problems of labor consumption, reduced processing quality and processing efficiency, delay in construction period, etc., to avoid worker burns and inaccurate docking effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

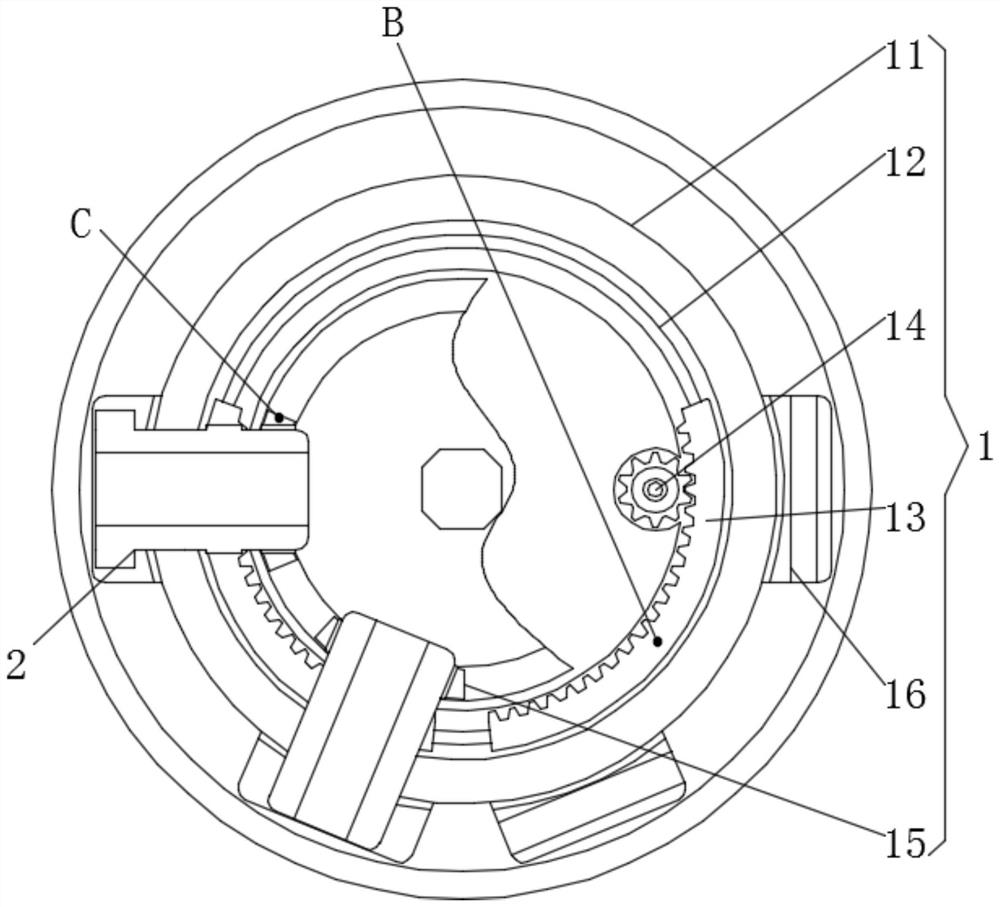

[0027] see figure 1 and Figure 5-8 , a multifunctional processing platform for steel structure design and processing, including an angle adjustment mechanism 1, the angle adjustment mechanism 1 includes a base 11, the inside of the base 11 is provided with a circular chute that is adapted to the support frame 15, the base The inside of the base 11 is provided with a turning groove adapted to the arc rack 13, the front of the base 11 is provided with a chute adapted to the flip clamping mechanism 2, and the outside of the base 11 is provided with a dovetail ring adapted to the flip seat 16. The chute, the inside of the base 11 is fixedly connected with a dovetail slide rail 12, and how the dovetail slide rail 12 slides is connected with an arc-shaped rack 13, and the bottom of the arc-shaped rack 13 is provided with a dovetail chute compatible with the dovetail slide rail 12 , the top of the arc rack 13 is provided with a threaded through hole, the arc rack 13 is meshed with ...

Embodiment 2

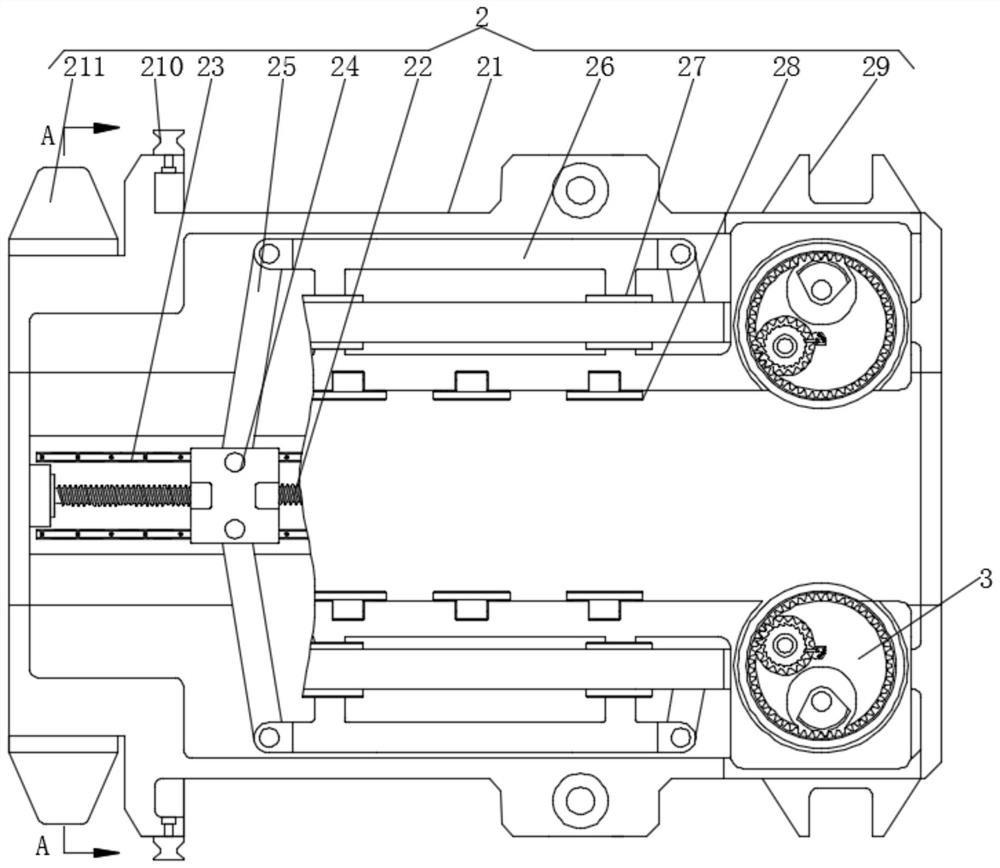

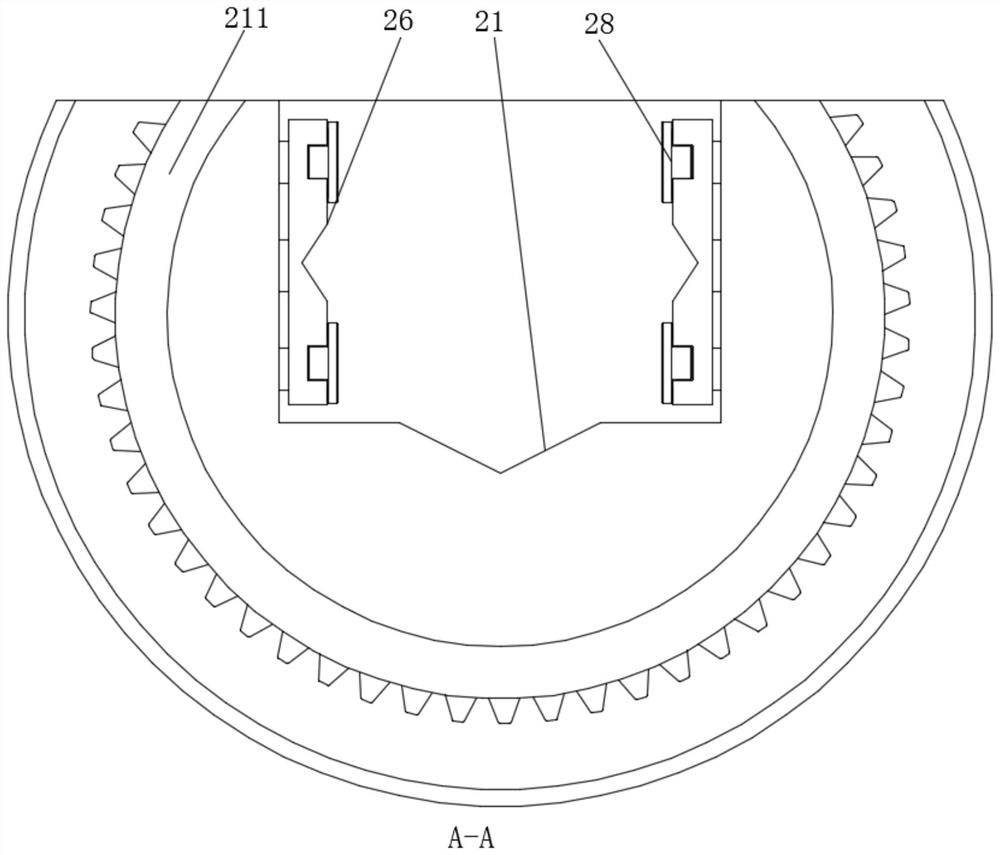

[0029] see Figure 1-4 and Figure 9, a multifunctional processing platform for steel structure design and processing, characterized in that it also includes a flip clamping mechanism 2, the flip clamping mechanism 2 includes a clamping seat 21, and the internal rotation of the clamping seat 21 is connected with a clamping Screw rod 22, the inside of clamping seat 21 is fixedly connected with fixed slide rail 23, how sliding of fixed slide rail 23 is connected with clamping carriage 24, and the outer side of clamping carriage 24 is rotationally connected with support bar 25, and clamping seat 21 The inside of the linear bearing 27 is fixedly connected with a linear bearing 27, and the inside of the linear bearing 27 is slidably connected with a clamping frame 26, and a contact seat 28 is threaded between the clamping frames 26, and the outer side of the clamping seat 21 is fixedly connected with a limit chute 29 and an arc. Shaped slide rail 210, the left side of clamping sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com