An ultrasonic welding equipment for cutting weldment residues based on different diameters

An ultrasonic welding and residual material technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as affecting enterprise benefits and reducing actual production efficiency of enterprises, reducing subsequent processing procedures, reducing differences, and reducing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

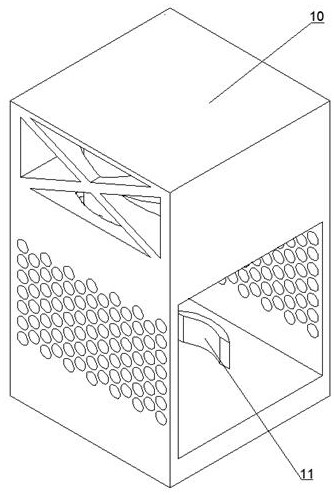

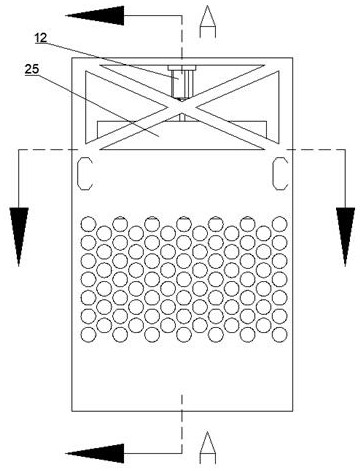

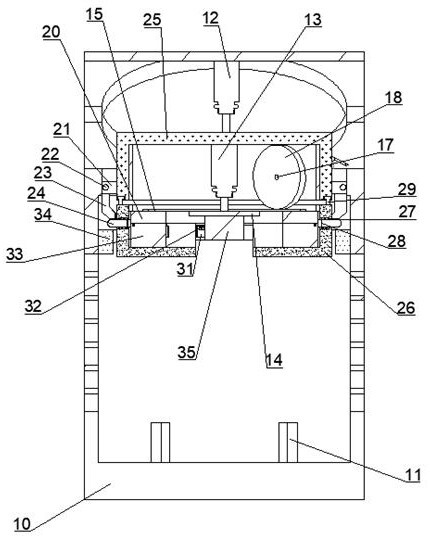

[0028] like Figure 1-10 As shown in the figure, an ultrasonic welding device for cutting weldment residual materials based on different diameters includes an external frame 10, and the bottom wall of the external frame 10 is symmetrically provided with clamping seats 11 that can move relative to each other, An external cylinder 12 is fixedly connected to the inner top wall of the external frame 10 , a fixed sleeve 25 is fixedly connected to the extending end of the external cylinder 12 , and a built-in cylinder 13 is fixedly connected to the inner top wall of the fixed sleeve 25 , the outer frame 10 is provided with an ultrasonic welding device S1 that uses the built-in air cylinder 13 as the main power to enable the ultrasonic welding mechanism 35 to perform ultrasonic welding on the weldment placed between the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com