Three-jaw chuck clamping reliability detection device and judgment method

A detection device, three-jaw chuck technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems affecting the stability of machine tool processing, affecting the processing accuracy, positioning error, etc., to reduce waste products The number of times, the guarantee of accuracy, and the effect of reducing processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

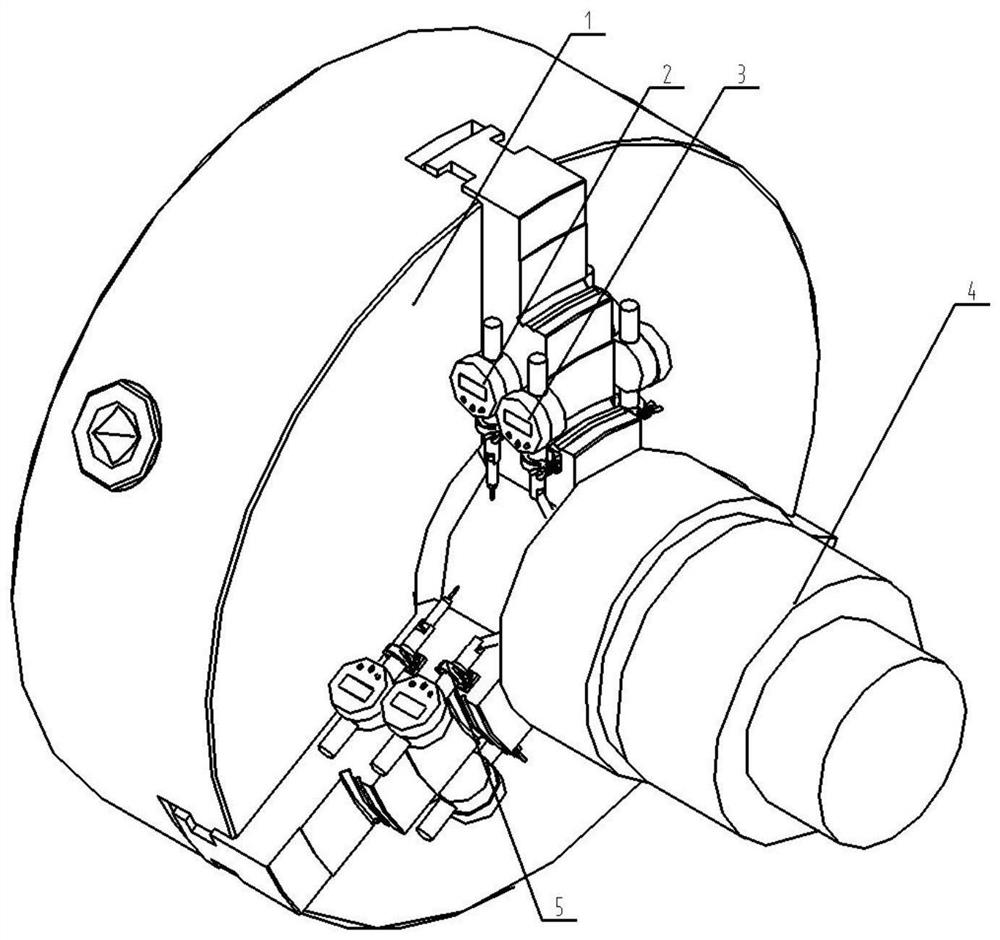

[0028] Such as figure 1 , figure 2 As shown, a three-jaw chuck clamping reliability detection device is installed on a lathe 6; the three-jaw chuck clamping reliability detection device includes a three-jaw chuck 1, and a workpiece 4 is positioned by the three-jaw chuck 1. Tight, the two sides of the three claws of the three-jaw chuck 1 are respectively symmetrically installed with the circumferential direction detection dial indicator 2 and the end surface direction detection dial indicator 3 through the fixed bracket 5, and the fixed bracket 5 is fixed on the three-jaw chuck by screws 1 on the jaws.

[0029] The end face direction detection dial gauge 3 is installed on the side close to the end face of the workpiece 4, and the end face direction detection dial gauge 3 probe is in contact with the end face of the workpiece 4; the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com