Grinding tool kit, equipment and method used for rolling surface finishing of tapered rollers

A technology of surface finishing and tapered rollers, which is applied in the field of precision machining of bearing rolling elements, can solve problems affecting the number of tapered rollers, unfavorable comparative processing, and affecting the size consistency of the rolling surface of tapered rollers, etc., to achieve the rolling surface size The effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Example 1 of the lap kit: a lap kit for finishing the rolling surface of a tapered roller.

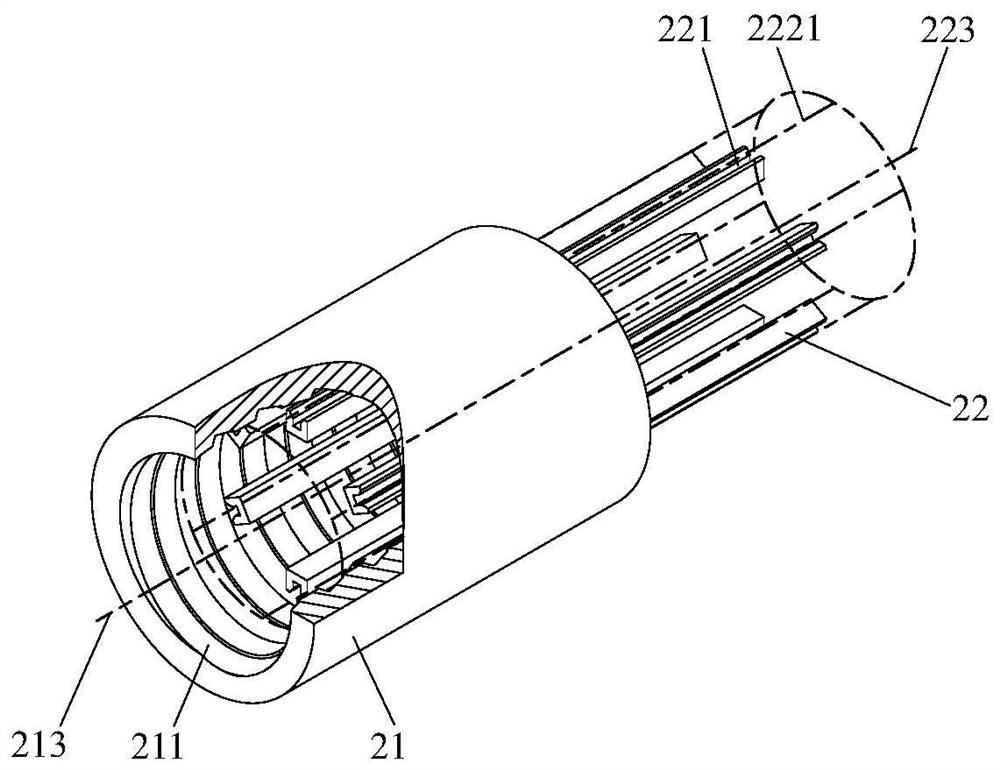

[0092] Such as Picture 1-1 As shown, the grinding kit includes a grinding sleeve 21 and a grinding bar assembly. During the grinding process, the grinding sleeve 21 is coaxial with the grinding rod assembly. In the figure, the mark 213 is the axis of the grinding sleeve 21, and the mark 223 is the axis of the grinding rod assembly, and the grinding rod assembly runs through the grinding rod assembly. The above-mentioned grinding sleeve 21. The inner surface of the grinding sleeve 21 is provided with one or more spiral grooves 211, and the spiral grooves 211 are cylindrical spiral grooves. The grinding bar assembly includes no less than three grinding bars 22 distributed in a circular columnar array, the surface of each grinding bar 22 opposite to the inner surface of the grinding sleeve 21 is the front of the grinding bar 22, each The front surfaces of the bars 22 are each pr...

Embodiment 2

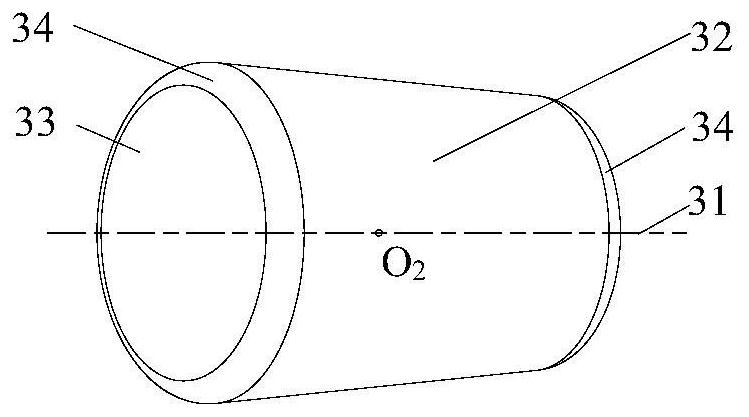

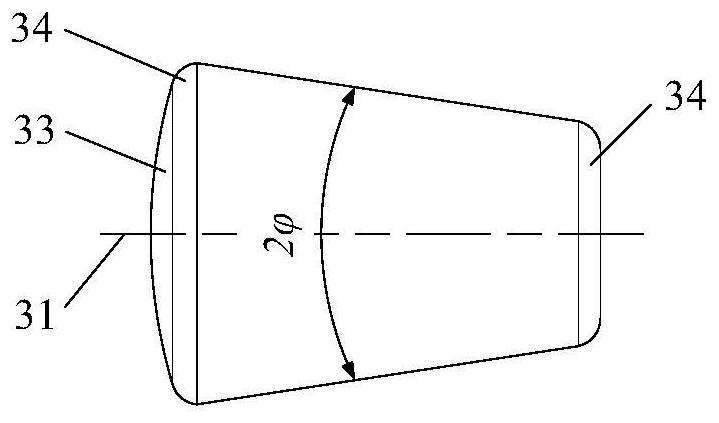

[0109] Example 2 of the lap kit: a lap kit for finishing the rolling surface of a tapered roller.

[0110] The main difference between the described lap kit and the lap kit described in the lap kit embodiment 1 is:

[0111] The surface of the big end includes the spherical base surface 33 of the tapered roller or includes the rounded corner 34 of the big end of the tapered roller or includes the spherical base surface 33 and the rounded corner 34 of the big end.

Embodiment 3

[0112] Example 3 of the lap kit: a lap kit for finishing the rolling surface of tapered rollers made of ferromagnetic materials (such as GCr15, G20CrNi2MoA, Cr4Mo4V30, etc.).

[0113] The main difference between the described lap kit and the lap kit described in lap kit embodiment 1 or lap kit embodiment 2 is:

[0114] The grinding sleeve 21 is made of magnetically permeable material, as shown in Figure 2-1(a) and Figure 2-1(b), Figure 2-1(b) is an enlarged part of C in Figure 2-1(a), A cylindrical magnetic structure 217 is embedded in the solid interior of the grinding sleeve 21 to form a grinding sleeve magnetic field in which the magnetic lines of force are distributed in the axial section of the grinding sleeve 21 in the grinding processing area, and the mark 2171 is the grinding sleeve Magnetic field lines. The spiral groove working surface 1 21111 is embedded with one or more spiral ribbon-shaped non-magnetic materials 218 along the scanning path A, so as to increase th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com